How to sheathe the balcony with your own hands

Finishing and insulation of the balcony is a very necessary occupation, although it is quite troublesome. Many decide to sheathe the balcony with their own hands and do it quite successfully. After reviewing this article from beginning to end, you can easily trim your balcony or loggia.

Where to begin

In order for the trimming to last as long as possible, it is necessary to prepare and strengthen the balcony. If you only need to make the outer skin, then no special preparation is required. Otherwise, the work will be more time consuming. Therefore, it is obvious that the facing of an unheated balcony will be faster than that of a warmed one.

If you need to create thermal insulation, then first we sheathe the inner wall with insulation, after which we make the sheathing and only after that we cover the balcony from the inside with plasterboard or other suitable material.

How to sheathe?

What material to choose for plating? The question is quite complicatedas now there is a huge amount of materials that differ in appearance, quality and many other properties.

Drywall

Drywall finishing is very popular. It is quite possible to make the facing independently, having at hand sheets for covering and standard tools. The advantages include several parameters: fire resistance, durability, ease of installation. The only and main drawback of drywall is fragility, because of which it is not possible to mount anything on the walls sheathed by this material.

MDV panels

This type of material is no less popular, as it is fairly simple to use and affordable for most people.

The advantages of DVV are many:

- Beautiful appearance;

- Wide selection;

- Easy installation;

- Low price;

- Easy to care.

But without flaws, this was not done. This may include insufficient strength, sensitivity to moisture and high temperatures.

Finishing "block house"

Not so long ago, the material appeared in the construction market has gained great popularity, as it has an excellent appearance.There are two types of material: imitation logs and imitation timber. Both options have the same properties, and differ only in size.

Advantages:

- Neat appearance;

- Natural and eco-friendly material;

- Keeps warm;

- Easy to assemble and maintain.

Disadvantages at the “block house” is not observed, but if you do not cover the panels of wood with varnish or paint, then they will very quickly become unusable.

Plastic

Plastic in the modern world is widespread. Many prefer PVC panels when covering the balcony. That's because they have a huge list of positive properties:

- Safety in case of fire;

- Environmental friendliness;

- Easy to install;

- Long service life;

- Ease of care;

- Large selection of colors;

- The best value for money.

Cons, as such, no one noted.

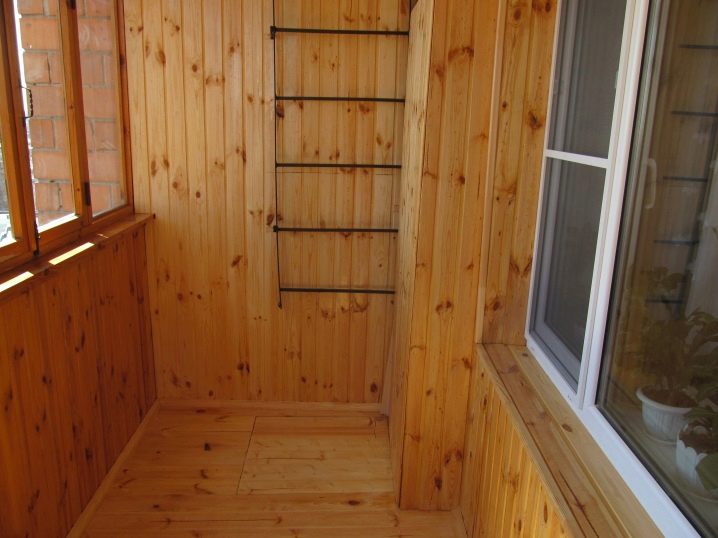

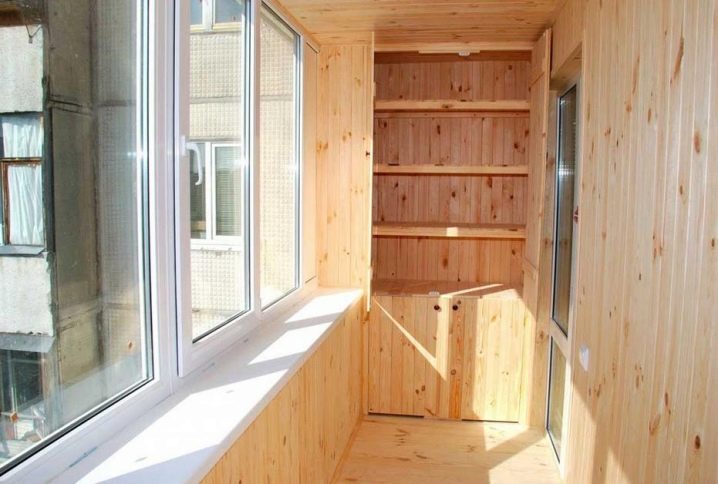

Clapboard

Once this material was at the peak of popularity, until it was pressed by the “block house”. This cladding material is made from a wide variety of wood species such as pine, aspen, larch, linden, oak and ash. The balcony, lined on all sides with clapboard, looks very attractive.

It has many advantages (ease of installation, appearance, long service life, environmental friendliness, etc.) and one drawback, which is the flammability of natural material.

The price and quality of lining depend on a class of production. There are several of them:

- Premium;

- "BUT";

- "AT";

- "WITH".

The higher the class, the higher its quality and price, respectively.

Plating process

To independently sheathe a balcony, you need to explore a relatively simple technology works. Each type has a general principle: you must first sheathe the most extensive areas, gradually moving to smaller ones. There are also differences, so when working with some separate material, it is necessary to take into account its features.

Clapboard

Since this material is natural, naturally, it is susceptible to infections with mold and various small parasites. Therefore, it is just necessary to process all walls and crate with special means.

Sheathing clapboard can take place in two ways: open and closed. Through the first, you can get a completely flat surface. Lining in this case is fastened with the help of screws or ordinary nails.

The second option is to mount the panels together with special clips. Due to this, the skin can be easily removed completely, or from time to time to replace individual boards.

Plastic

Plastic sheeting is either siding or PVC. The first option is much more convenient, since it already has the necessary and convenient dimensions. While PVC needs to be independently cut into various pieces.

In the first case, it is necessary to fix the fastening profile. After that, you need to set the starting level on which you can mount a variety of profiles. Further the finishing level on which establish a siding panel is fixed. Work should start from the bottom.

To get started with PVC, you must first make a strong crate. Then the panels are cut into pieces and fixed to the structure. The joints of the panels are connected by a special profile.

Be sure to make sure there are no slots and do not forget to close all corners.

MDF panels

Before covering, it is necessary to make and fix the crate of wooden bars. Then use the glue to fix the guide panel.Each subsequent panel is inserted into special holes in the previous one and additionally glued to the bars. The last panel needs to be cut and fastened as tightly as possible.

Drywall

Drywall is very fragile, so you need to make a metal frame for it. The width of each cell should not be more than 50 cm. It is best to work with such material in pairs, since drywall has large dimensions and weight.

Massive sheets are fastened by means of self-tapping screws, which need to be screwed on two pieces into each cell at a short distance from each other. From time to time it is necessary to check the level of coverage using a special device. Be sure to after fixing the sheets need to miss the mark all the joints. Then you can safely get to the decorative part of the work.