Condensate in the winter in the waiting room: how to get rid of?

After construction, it is time to use the bath. Since it is used all year round, in some cases, many have noticed the appearance of condensate in the waiting room (especially in winter). This unpleasant phenomenon causes the metal parts of the interior to rust, it leads to the appearance of mold.

The reasons

Many have noticed that droplets of water are formed on a glass jar that is sterilized over steam (the jar is sweating). After heating the banks, the droplets cease to appear. The same happens if a cold metal spoon is brought to the tip of a boiling kettle. Some time after the spoon is heated, the droplets will no longer form.

The main reason for the formation of condensate is the fact that from the heated water vapor that falls on a colder surface or in a colder environment, water begins to form in the form of small droplets.

For the same reason, rain falls. The heated water vapor enters the upper (colder) layers of the atmosphere. In the same way there is moisture on the walls and ceiling of the waiting room. At the same time wet, damp walls and ceiling. Accumulated water droplets drip down onto the floor, it becomes wet.

There are several reasons for the appearance of condensate in the waiting room:

- High humidity in the room. Humid air is collected in poorly ventilated parts, moisture and dampness appear.

- Warm air enters the cold walls of the bath.

- Lack of ventilation in the room or its lack of functioning.

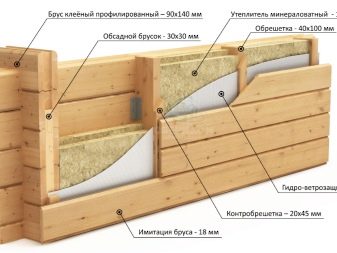

Besides the reason for the appearance of condensate is the lack of necessary insulation between the inner coating of the walls of the dressing room and the outer wall of the bath. As a result, the coating is constantly cooled. All this leads to the constant presence of condensate. It impairs the properties of the material from which the building is built, reduces its durability. Falling on electrical wires, water droplets can cause a short circuit.

One of the reasons for the formation of condensate may be the flow of water under the floor directly from the bath itself.Therefore, it is necessary to ensure that there is no moisture through the cellar. If there is a leak, it is necessary to do everything to eliminate it.

This unpleasant phenomenon may be accompanied by the rotting of the materials of which the bath is built. These are mainly wooden parts of the building. There may be a large amount of mold and mildew on the walls and ceiling, as well as under the lining. Rust forms on metal surfaces.

Remedies

There are different methods of getting rid of condensate in the waiting room. Among them there are several that can remove this negative factor.

- Ventilation. This method is the simplest and is used when it is not possible to use other methods. Airing allows to remove a part of damp air from the room. This leads to a decrease in total moisture and cessation of condensation. To air the waiting room, just open the front door for a while. Walls and ceilings must be wiped off from moisture.

- Natural ventilation system. With this method, air ducts are installed at the bottom and above,which provide natural movement of the air flow. For effective ventilation, the duct diameter must be at least 10 cm.

- Installation of forced ventilation systems. Even the most insignificant system of forced airing will allow to remove humid air from the room, rather than eliminate the main cause of condensate formation. At the same time in the air ducts install small fans, which provide continuous movement of the air flow. Fans are installed in the lower and upper ducts.

- Thermal insulation. At the same time, the installation of heat-insulating panels is carried out in order to eliminate cooling of the internal facing panels of the walls and ceiling.

- Installation of an additional stove or fireplace. One of the most difficult and expensive ways to deal with condensate. This provides additional heating of the room and walls, this eliminates the cause of condensation.

In this case, additional free space is required in the dressing room for the installation of a stove, heater or fireplace, as well as provision of additional exhaust.

Conclusion

Eliminating the causes of condensation in the waiting room, care should be taken to protect the internal parts of the structure (especially wood and metal) from the formation of fungus, mold and rust. For this wooden parts are treated with special antiseptic compounds that provide moisture resistance and antifungal effect. All wiring for electrical installation, indoor lights and switches should be used with increased protection against moisture and corrosion.

The floor in the dressing room is recommended to cover with ceramic tiles, which are not susceptible to corrosion and resistant to moisture.

Taking into account all requirements in the construction of the bath (including the possibility of condensate formation), the processing of internal parts with modern materials, the use of efficient and high-quality heating and ventilation systems will provide a cozy atmosphere and a great rest in the bath, its long-term operation. Accounting for all the nuances will get rid of condensate.

How to get rid of condensate in the waiting room, see the next video.