Insulation for the walls of the bath: tips on choosing and installing

The bath should be warm and the stove plays a key role in fulfilling this requirement. But no heating will be sustainable, if not provided high-quality insulation of walls. And it has a number of features, unfamiliar to those who insulate only houses and ordinary outbuildings.

Special features

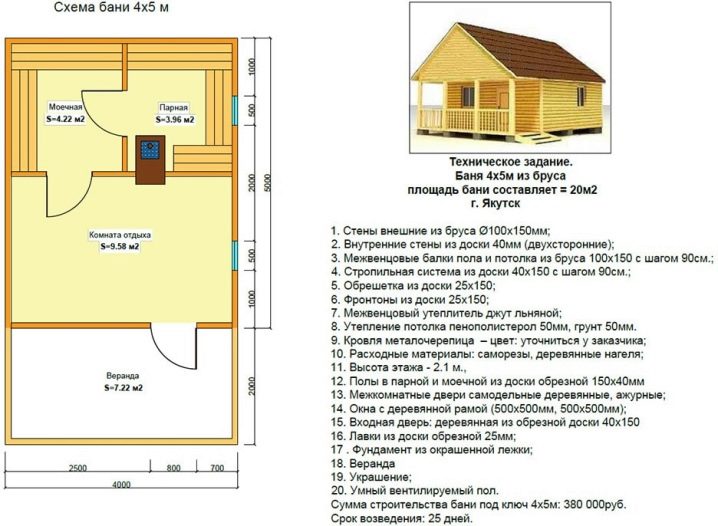

To insulate the walls from the inside is enough for a private house or an ordinary non-residential building. But in the case of the construction of the bath also requires an exterior trim insulation layer. The approach depends largely on what kind of structural material is selected for the walls of the bath.

Also taken into account:

- climate of the region;

- year-round or periodic use of the bath;

- required temperature;

- financial capabilities of customers.

Differences in the selection of heaters for different types of structures are associated not only with unequal heat capacity. Experienced builders take into account the bearing capacity - if it is too small, the insulating material simply does not hold.In the case of log cabins, shrinkage can lead to the formation of new and the opening of old cracks.

Kinds

There are dozens of varieties of insulation on the market, but for a bath you can only use those that:

- are safe in the ecological and sanitary relation;

- excellent resistance to moisture;

- prevent bacteria and fungi from multiplying;

- many years keep a stable form;

- and, of course, provide maximum heat retention.

Warming stone wool is the most effective solution, because no other material can provide such a low thermal conductivity. Organic heat-insulating materials have a long history of use and are undoubtedly safe. Chips and sawdust, felt and flax tow do not exhaust their diversity. Modern industry has established quite a long time the release of plates on the basis of reeds, shavings or peat.

It is important to understand that in the hot bath rooms such a solution is unacceptable.

Even an old wooden bath is quite acceptable to insulate with polymeric substances. So, foam is great for the ceiling, it maintains contact with moisture and considerable temperature.Mechanical processing of various types of foam is very easy. Foamglass is most often used on the most problematic surfaces, when it is difficult to fix something else.

Problems can be associated with chemical composition - with a significant warming up the release of toxic substances begins.

Often, the choice again refers to basalt, dolomite or diabase wool.

These materials are suitable for cinder blocks, and expanded clay, and for brick baths. They are not spoiled by rodents, and it is very easy to mount the necessary layer.

Glass wool is even easier to install, but not so resistant to high temperatures.

To avoid contact with moisture and to reflect heat inside it is recommended to use foil.

Foiled ready-made heaters are placed mainly on the ceiling and prevent them from leaving the steam room to the most important thing in it, that is, infrared rays.

In order to insulate a chopped bath, for centuries various types of moss, hemp and jute have been used. But each type of such fiber causes a stir in birds and insects. The solution was found in their combination. The result is achieved due to the fact that the combined material is not recognized by animals as something familiar and is not taken apart.

When using plant materials is very important high-quality drying.

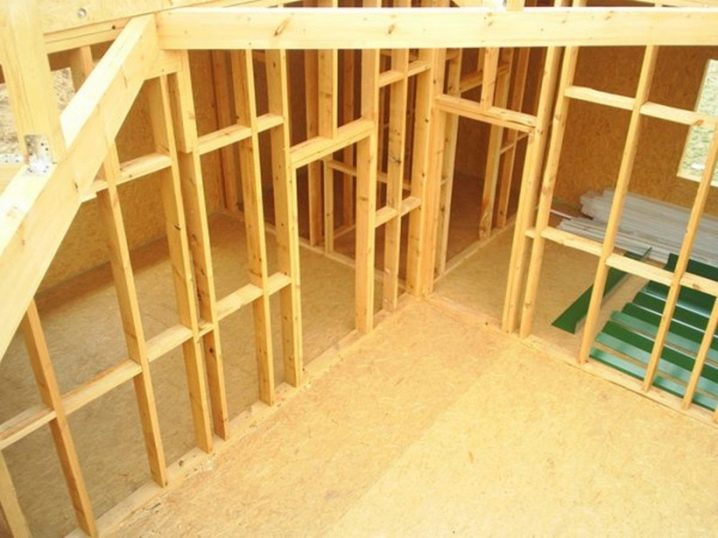

It is necessary to warm a bath from blocks differently, than constructions from a log. Preferred solutions are fiberglass and mineral wool.. Regardless of the type of insulation used and the basic structures, a thorough vapor barrier is required.

A wooden crate should be installed on top of the cinder block, gas block or gas silicate block.. Without it, no structures and insulation will not stick to the surface.

The same approach in block construction applies to the ceiling decoration. If fiberglass is used, it is strictly impossible to cover with both sides of the foil. Otherwise, the passage of air and wet steam to the outside will be disturbed.

The brick bath is sometimes insulated with penoplex. But for it only internal insulation is needed, there should be no finishing layers outside - this will only cause overspending on the masonry heating.

How to choose?

But the choice of insulation material can not be uniform for the entire bath as a whole. There are too many differences between the individual rooms. In addition to the washing and steam rooms, you must also place a dressing room and a dressing room inside (often these rooms are combined into one if there is not enough space).The air in the vestibule is always cooler than in other compartments.

Paints and plasters, which manufacturers proudly call heat-insulating, provide an insufficiently high level of thermal insulation, and can only be an auxiliary link in it.

Bulk material is used mainly for roofs and floors. It is much harder to lay it inside the walls, and for this you need well-laying. Brick dressing rooms are mainly insulated with foam plastic due to its ideal compliance with the required parameters and reasonable prices.

The frame fixing of the insulation on a wooden beam is made for finishing:

- clapboard;

- plastic panels;

- boards;

- professional sheet and siding.

The mounting step of the frame is determined by the width of the lining being created. Considering the inevitable crumbling of the foam during cutting, a certain amount of material should be reserved.

If the humidity in the sauna waiting room is relatively low, it is acceptable to use mineral wool.. They fix it in the same way as foam plastic. If the gaps of the racks are occupied by communications, a layer of unedged board is placed above the frame, and heat protection is already mounted on it.

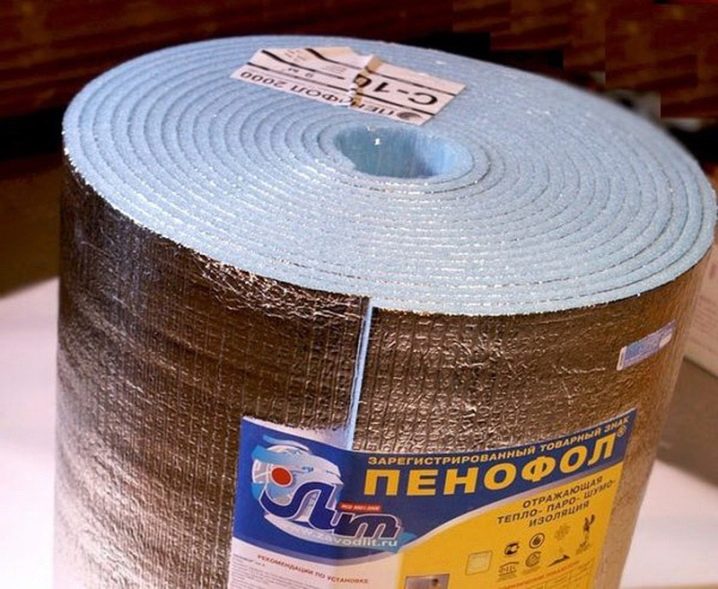

Internal warming of the dressing rooms is most often produced by penofol, which stops 97% of the thermal energy.

Given the small thickness, this coating will allow the most efficient use of useful areas. Where heating devices are attached, penofol should be left without finishing. It can be used in the composition of the warm floor. Laid out under pipes or an electric cable, penofol increases heating efficiency.

When forming the slab basement, the dressing room is insulated on wood lags. Joining of a bar to a plate is made by self-tapping screws, intervals need to be filled for 100%.

In the case of pile foundation equipment, all structures are installed on steel or wood beams. They are treated, respectively, with antiseptics or anti-corrosion mixtures. The heat-insulating layer should be covered with a vapor barrier in the form of a membrane, which stops the vapor condensation inside the thermal protection.

Requirements for thermal insulation in the steam room will be significantly higher, but to reduce the need for it will help:

- installation of solid glass;

- formation of a high threshold with a low door;

- the acquisition is not a simple stove, and the heater;

- elaborate configuration of the bath;

- high-quality ventilation.

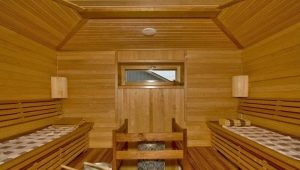

Waterproofing material for a steam room should easily carry even very intense heat. Kraft paper copes well with this task. The walls of the steam rooms are insulated with sphagnum (laid in between the crowns) and tow (overlapping cracks). In fact, insulation is achieved with the help of construction moss, extruded polystyrene foam, foam plastic and foam polystyrene.

The advantage of synthetic materials are:

- resistance to mechanical failure;

- long period of work;

- excellent heat retention.

The steam baths of frame baths are often insulated with basalt wool.

It is chosen both because of its excellent practical qualities, and because of its cheapness. Expanded clay, too, is inexpensive, but it will have to fall asleep inside the walls of 30 cm at a minimum, which greatly complicates the work.

Ceilings can be insulated with clay.; if they are filled with sawdust, earth must be placed on top of the insulation layer in order to guarantee fire safety. From modern solutions, experts recommend basalite, izospan or overlapping plain foil layers.

Warming scheme

When the means for warming the bath is selected, you need to figure out how to better warm the room with their help. Wooden walls are supposed to be covered with foil vapor barrier. And Foamed polyethylene with an external aluminum layer will not work, you need a strictly clean foil. She nailed directly to the crate of wood. At the joints, at least 10 cm of overlap is made, and it must be glued with aluminum tape for maximum tightness. Slats are required to be used for fixing parts for interior decoration.

A similar scheme is practiced in buildings made of gas silicate and foam concrete blocks made of brick. When working outside the list of permissible insulation is much more than inside, because the risk to health is significantly reduced.

External insulation during construction, the first step is to work with the foundation. If you do it later, you will need to break the blind area and then create it again.

The base and basement is undesirable to insulate with foiled materials. - they are too thin and do not allow to achieve the desired effect. Mineral wool is also no good.It is too easily damaged by water.

Plate insulation is required to be laid under the pavement to prevent freezing of the soil next to the building. Concrete paving and exterior trim basement are formed only after that.

If you correctly install foam and other synthetic insulation, they can be laid even in the floor of the bath.

The preparation of the concrete screed, which completely isolates the insulation layer from the inside of the room, becomes the right step.. Begin work with the creation of an inclined surface, over which a layer of waterproofing is laid out, followed by insulation. Then lay out a vapor barrier film that serves as the basis for concrete. The middle part of the structure should be equipped with a drain drain pipe.

A simpler solution is mixing concrete with foam or vermiculite.

This step allows you to get at the same time a strong and heat-holding layer, due to which there will be no need to place whole plates under the screed.

If to use expanded clay, it will be possible not to care at all about isolation from the internal volume of a bath. Mineral is poured into the void separating the finishing floor from the draft; in another embodiment, it is laid out around the columns of brick. Because claydite easily gets wet, need to take care of powerful ventilation, which will contribute to its accelerated drying. It is possible to choose expanded clay and for warming bath ceilings under a cold roof, so long as the filing is strong enough.

Warming of attics above the steam rooms using sawdust is permissible only after mixing them with clay.

The formed solution is laid out between the lags. Otherwise, the pairs coming from below will saturate the lined insulator and worsen its characteristics. The combination of sawdust and cement recommended for ordinary homes should not be used.because it spoils too quickly.

It is important not to forget about the warming of the entrance doors using felt padding, thermal curtains or foam coating.

How to calculate the required amount of material?

When the scheme of work and the type of material used are completely clear, it is time to estimate the thickness of the cake being created on the basis of thermal calculations.Only specialists can competently execute them, so it’s not at all embarrassing to turn to ordinary customers and amateur builders for help.

In order for the inner and outer layers of thermal protection to meet the necessary requirements, you need to take into account a number of nuances:

- total area;

- useful area (the one in which steam is circulating);

- number of rooms;

- climatic conditions;

- type and thickness of construction materials;

- the strength and direction of the prevailing winds;

- type of bath and the level of humidity in it.

The order of work

When insulating baths with their own hands, they will definitely need a hammer, a saw on wood, a drill, and a doboynik. If the tree is to be used for interior trimming, it is recommended to use alder or linden plank. They perfectly resist contact with water and do not heat up even in overheated air.

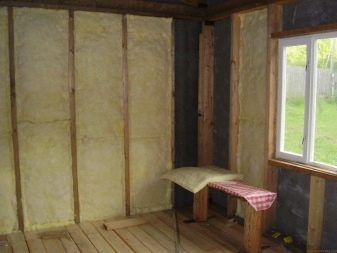

The walls are insulated first., and for this purpose lath is always crammed. It can be both wooden and aluminum.

The next step in the step-by-step instruction is the installation of a frame that will ensure reliable ventilation.It is advisable to put the frame vertically so that the lowermost parts of the skin are horizontal and subject to simple replacement.

A vapor barrier is placed on top of the rolled or slab insulation, which is fixed on slats approximately 0.3 cm thick each. Next comes the turn of the plating. The lining is fastened with the help of clamps or clips, and the boards are nailed with galvanized nails, which are driven tightly with the help of a doboynik.

Be sure to warm the ceiling. Most often, such work is carried out outside, but when using a lean-to roof, it will be too laborious. Then finishing is done inside, the sequence of steps is the same as when working with walls. The difference is that it is necessary to attach the plates on the "fungi". Insulation can not be put a layer thinner than 0.2 m, because otherwise the ceiling will be strongly pressed the steam room. The overlap of the vapor barrier should be the same size.

Inside the bath of brick also mounted rack frame. Instead of mineral wool, penoterm is often placed in it. - it is more reliable and not so quickly destroyed by the action of water.Docking points overlap with thin, but relatively strong slats.

It is recommended to impregnate draft wooden floors with waterproofing and rot-inhibiting compounds.

It is recommended to create a ventilated floor - it will be safer and will last longer, will provide perfect comfort in the bath.

Tips

Even careful selection of materials and strict adherence to standardized technology may not be successful. This is most often associated with ignoring the subtle, non-obvious at first nuances. The outer edges of the foundation should be provided with ventilation holes, then water will not collect at the bottom, creating a cold center.

To improve the vapor barrier properties of Kraft paper, it is recommended to cover it with a mixture of sawdust and clay or other similar materials. Experts recommend carefully inspecting the perimeter of the windows, especially the part that is under the window sill - this is where most of the cracks appear that require closure of the insulation.

When choosing the door to the entrance to the steam room you need to make sure that they do not have gaps and are well fitted.

For those suffering from allergies and respiratory disorders, it is better to avoid using glass wool.Even the insignificant probability of its entry into the body outweighs the positive qualities of this insulator.

Environmental cotton wool is less dangerous, but too sensitive to the harmful effects of water. When selecting materials with increased environmental and sanitary characteristics, it is always necessary to find out how great is the risk of their ignition or the occurrence of foci of mold.

Thermal insulation of the bath is too important work to violate the manufacturer’s instructions. You should get acquainted with them completely before starting work. If the foiled material is mounted, it should be placed with the metallized film inside. It is unacceptable to install insulation thicker than the installed bars. Also, do not disturb the typical order of the layers.

Fastening on a wooden wall is more correct than nails, not screws.

It is recommended to leave a gap of 0.8-1.2 cm from the insulating material to the trimmed surface, which provides internal air circulation. The layer of thermal protection at the floor should be thicker than on the walls. Whenever possible, it is better to put the material on this overlap on top, not bottom.Underfloor waterproofing is most often created using roofing felt or solid polyethylene.

Finishing the floor should be done as carefully as possible, because the slightest penetration of moisture into the insulating layer is completely unacceptable. If expanded clay is used, under the floor it should be twice as thick as in the walls, and this is the minimum figure.

For a steam room, it is recommended to equip a ventilated facade.

Sealing windows with jute or any other fiber is much more practical than using silicone sealant. Even in places with a comfortable climate, it is recommended to make a heat shield with a steam bath at least 150 mm thick.

It is impractical to use for thermal insulation inside roofing paper and glassine. The most convenient foil for work is 65 microns thick..

Concrete and brick baths most often outside are covered with a layer of soft thermal insulation (produced in the form of mats). Foil must be put on top and then finishing finishing material is mounted. At the very bottom, it is advised to install the profile in the form of a letter P, which will prevent the heater from sliding down from the wall and thereby increase the reliability of the structure.

For information on how to insulate the walls of the bath, see the following video.