Gate Automatics: Selection Criteria

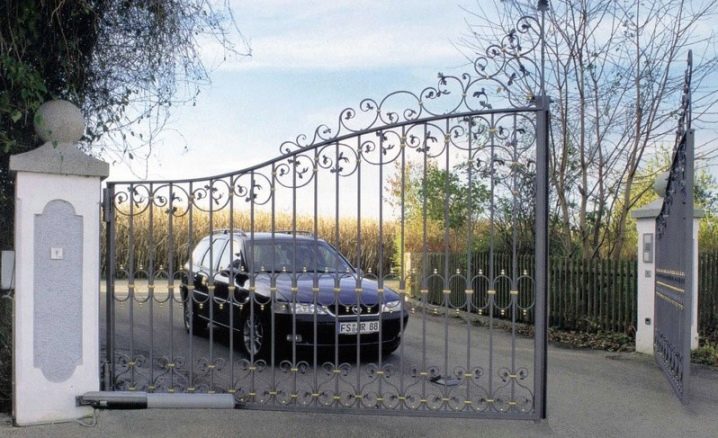

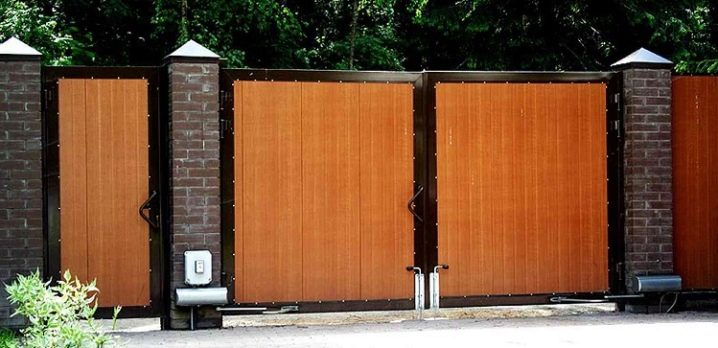

Modern technology has allowed to create automation for the gate, which provides ease of operation. You no longer have to spend time and energy plowing and locking the gate. The movement of the sash is now possible to implement by pressing a button on the remote control.

In addition, in industrial areas they are indispensable, as they allow you to freely open massive structures when driving vehicles.

Specifications

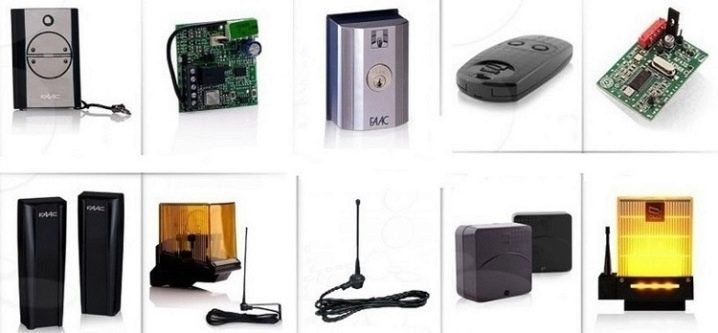

Gate automation has its own advantages and disadvantages, which are individual for different models. Most consumers buy a kit, which includes an electric motor and additional devices. Some manufacturers put an instructional video disc inside and a backup button that replaces the remote control because of unforeseen circumstances.

The drive deserves attention due to the advantages that allowed gaining popularity in the market:

- Speed. Power connection mechanism allows you to quickly open the sash. A single cycle is produced in 15 seconds.

- The minimum area. Installation of the device is carried out in a limited area, hidden behind the gate. Thus, the design does not prevent the movement of vehicles.

- Convenience in operation. The manufacturer is focused on comfortable use of the device, whose operation is silent and reliable. Each model is capable of performing up to 50,000 work cycles.

- Additional security. The installation of an electric motor blocks the flaps in the mounting msta, thereby providing an internal layer of protection.

- Mechanism Closers contribute to the automatic closing of the valves without additional manipulations with the control panel.

- Unexpected power outage is not a hindrance to the movement of the valves. When purchasing a set, the owner receives a key that allows you to open the sash manually.

However, along with the advantages, electric drives have a number of disadvantages.For example, the main disadvantage lies in the supporting structure, which must be sufficiently massive and wide enough to support additional weight.

Mounting the actuator damages unreliable support. To avoid the unpleasant effects of the collapse is possible due to the strengthening of the pillars.

The second disadvantage for some models is the narrowing of the choice of finishing material for the gate. For a swing type, it is not easy to select forged decorations that would not prevent the replacement or removal of an electric motor in the event of a breakdown.

Functions

The main advantage of electric drives is comfort. When transporting vehicles, it is no longer necessary to leave the vehicle interior several times in order to manually open and close the valves. Even the gate will be able to automatically admit and release pedestrians, it is necessary only to improve it.

However, the comfort functions do not stop:

- Automation takes the security level to a new level. Without a control panel, opening a gate without a lock becomes an almost impossible task. In this case, the leaves protect the site from intruders and stray animals.

- The drive provides protection of the valves from strong wind fluctuations, as it is able to work regardless of weather conditions.

- Interlocking systems that read cards or receive a remote signal allow access control.

- Unlike creaking locks, the automatic mechanism works silently, contributing to ease of operation.

Electric drives save time and effort of the site owner, providing effective protection and convenience. The mechanism is represented on the market by a wide range that allows you to choose an individual model for any territory.

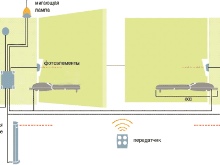

Manufacturers also offer various types of modifications that improve the performance of devices. For example, a system equipped with photocells or sensors of a certain type can detect an approaching object.

Thereby it is not necessary to spend time for control of shutters by means of the control panel. The gate automatically forms a passage and does not lose the safety function.

Types of drives

Automation for the gate is divided into three types:

- linear;

- lever;

- underground.

It is required to measure the distance between the hinges and the inner side of the supporting structure in order to clearly determine the choice. Linear electromechanism is used at a distance of less than one and a half centimeters, which determines the low price of this drive. Lever type is installed when the interval from 1.5 to 3 cm.

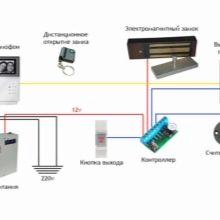

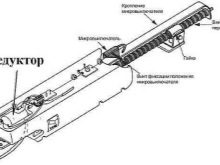

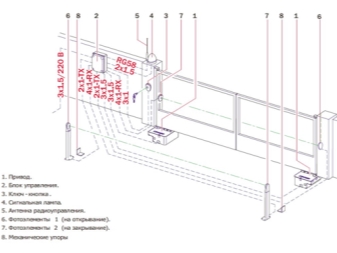

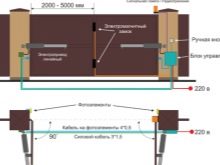

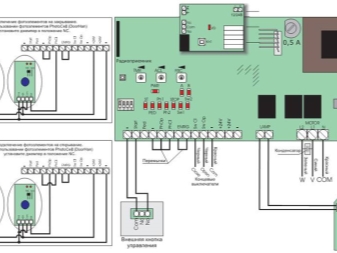

Setting up the scheme involves the installation of a set of equipment, and not just the installation of the drive. For self-installation will need to know the width of the door leaf and wind vibrations. Most consumers are afraid to do the installation by hand, but careful attention to details of the instructions will eliminate all troubles.

Linear type is the most common in the construction market due to the fact that it has clear advantages:

- the opening and closing drive of the gate can be located both in the upper part and in the lower part;

- the opening cycle has a slow action, which provides the undoubted advantage of the linear type over the lever;

- Programming the system at a slow speed increases efficiency and saves energy;

- when the current supply is cut off, it is easy to open the valves manually.

A linear type electric motor is installed on additional posts, which saves space on the site. However, a significant disadvantage in this case is the restriction of opening the gate to 90º. The angle of movement binds the passage of wide cars.

It should be remembered that the chain drive is designed for a weight of up to 600 kg, which limits the installation on sash widths up to 3 meters. For more massive automatic gates will have to use a hydraulic mechanism.

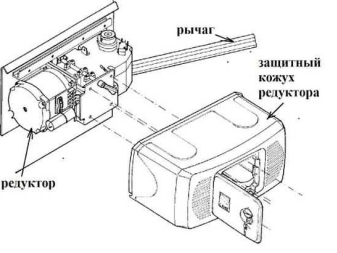

Among the electric drives, the lever mechanism is no less in demand, which is the best option for installation with your own hands. Installation is made easier thanks to its weight of 13.5 kg.

Levers work independently, therefore this type of mechanisms does not require deceleration. It remains reliable for a long service life, and does not limit the movement of the gate, contributing to the opening of the valves up to 120º. Installation of the structure is made only on massive pillars that can withstand the working return. At the same time, like the linear type, the levers are set for single sash weighing up to 600 kg.

The most expensive type of automatic mechanism is an underground structure. It is mainly chosen by the owners of large areas who want to maintain a harmonious landscape design. The system, hidden under the ground, preserves the aesthetic style of the wrought gate and the surrounding territory.

Under the ground is wet enough, which requires additional protection of the mechanism from damage. It is possible to avoid unpleasant consequences due to the use of a special box accommodating the entire drive system.. Protection is located on a single line with the roadway straight under the hinges of the valves. This location completely hides the mechanism from prying eyes.

The advantages of the inconspicuous mechanism do not end. The design allows you to increase the opening angle of the valves up to 110 º. Separate kits or technical modifications will increase the opening width to 360 º. The changes made do not affect the operation of the drive, which operates in the established smooth and silent motion.

Modern technologies have increased traction for a maximum weight of the flaps of 900 kg wide up to 5 m.However, it is better to entrust the installation of the system to specialists. The nuance is that the professional makes the installation of the drive in accordance with the design of the site.

Features of operation

The type of automation is selected depending on the type of gate and frequency of operation. The electric motor must be reliable, since it performs several functions, in addition to the comfortable movement of pedestrians and vehicles outside and inside the territory.

The mechanism is a system of access control not only private, but also folding premises. Thus, installation and operation of the electric drive is possible not only for residential, but also for production sites.

In the latter case, most of the fences should be massive and high, which directly affects the size of the gate leaf. At the same time homemade assembly is extremely difficult. It is better to entrust the installation to specialists.

However, the engine can quickly break if you do not follow several basic rules of operation:

- Manufacturers do not recommend leaving the gate half open. This situation increases the load on the electric drive, which often leads to breakage.Adjustment of the full cycle of plowing sash is necessary.

- It is necessary to clear the territory of plowing the gate from unnecessary items. Foreign objects interfere with the opening of the sash, which leads to overload and unnecessary costs of electricity.

- In winter, it is necessary to monitor the cleanliness of the lower sealing rubber, which is located just above the floor. Dirt or foreign objects can make opening the gate difficult.

- Cables require regular inspection and maintenance. To avoid gaps, experts recommend replacing worn and damaged parts in a timely manner.

- The manufacturer upon purchase gives a certain guarantee for products that can be replaced in case of untimely breakage or a defective device. However, the warranty ceases to be valid in case of replacement of the gate or in case of independent careless manipulations that caused the equipment to break.

Most troubles can be fixed with your own hands. For example, moving parts that require regular maintenance can be lubricated from time to time. Prevent metal wear and rust formation is possible due to the timely application of anti-corrosion coating.

Manufacturers

The abundance of goods sometimes leads to confusion and a complete misunderstanding of which drive is better. The leading position is held by Italian manufacturers who produce goods of the best quality. The secret lies in the fact that it was in Italy that the idea of remote control of external fencing was born.

It is possible to purchase automation for gates in the construction market by pre-assembled kit. but Before buying this or that product, you should review the reviews on various forums. Manufacturers often focus on one of the areas of extensive functionality, so manufactured products can be highly specialized.

It is recommended to build on the right direction when buying a device.

The most popular brands have several advantages, thanks to which they are leading in the construction market:

- Came - Italian manufacturer, which occupies a demanded position for 30 years, maintaining high standards of quality. Products are manufactured in a wide range that allows you to individually select the drive of interest.

- Comunello manufactures drives, ready for operation at a temperature of -35? С and with voltage drops. The manufacturer focuses on the strength of mechanisms, guaranteeing a long service life of 50,000 cycles

- Nice produces effective products that confirms its name, because the automation confirms reliability. The product is not damaged for a long time, and an affordable price allows you to purchase a product to various categories of consumers.

- Faac produces professional-class automatic drives. It is possible to install the equipment with your own hands, which is a big plus when buying. Hydrodynamic technology is superior to electromechanical, but it needs more attentive service.

- Alutech - domestic products that do not fail during the cold season. Automation is focused on work in harsh climatic conditions. The motor works both at low temperatures and in conditions of high humidity. Accordingly, the manufacturer guarantees a long service life for the drive. Clear instructions provide easy installation and ease of operation.

However, if the installation and purchase of automatic drives from well-known companies severely hits the wallet, it is recommended to purchase devices from China. Contrary to cheap prices, the products are not inferior in quality of operation and characteristics of Italian. Unfortunately, the materials used in the manufacture of low quality. Sooner or later, the design will require replacement, as low cost devices rarely allow themselves to be repaired. In recent years, Chinese manufacturers have raised the quality to a new level, thereby securing a place in the market.

Recommendations

Owners of private territories are often willing to handle the installation on their own, without the help of professionals. However, before carrying out manipulations with the electric motor, it is necessary to check the gate itself, lubricate the hinges or repair it if necessary. Strengthening of the supporting structure will also be required if it is unreliable. Brick and concrete pillars require additional reinforcement when installing the base of an automatic engine.

The state of the support pillars should be focused on when choosing a drive.Linear requires a distance of 150 mm, while the lever - up to 300 mm.

For installation, you will need a set of tools:

- screwdriver;

- roulette;

- drill;

- hammer.

To strengthen the frame, the device is welded to the bearing support with brackets. The wires must be carefully insulated to prevent damage. In winter, they can be damaged by low temperatures, and a short circuit can occur in the rainy season.

Professionals recommend that before use, reserve a centimeter of travel from a linear-type stem of a drive. After its installation, check the operation of the device. In the case of a smooth opening and closing of the valves, they begin to engage in special automation, which has switches. If it is not included, use closers. However, it is easier to purchase a complete set of equipment, since the assembly of different models can lead to a sharp closing of the valves.

If, when the mechanism is turned on, the door moves in the opposite direction, then the wires should be checked. In most cases, they are confused. It is necessary to rectify the problem, because the sash will function incorrectly, which will lead to breakage.

The final stage of installation is to connect the system to electricity.With a stable operation of the mechanism, they start adjusting, as well as installing additional devices in the form of sensors or signal lamps. In case of unforeseen circumstances, experts advise installing a backup button. It opens the gate when the remote is lost or broken for remote control.

If the installation causes confusion, then it is better to trust the experts in this field. In this case, the best option would be to contact the company that supplies the equipment. Employees are already familiar with the models and nuances during installation, so they will carry out installation work faster than specialists who have no experience with this type of device.

In case of lack of experience with electrical and mechanical types of installation work, professionals recommend contacting specialists for safety purposes. At the same time, agents at the conclusion of the contract provide a guarantee for high-quality installation during a certain period of operation.

The manufacturer often puts in a set of equipment training disc with all stages of installation. If the function of some details is not clear, then you can contact the consultation on the hotline.In most cases, the operator will be able to explain in detail all the steps when installing a particular model. The call is free and does not require participation and hiring a professional.

It is also necessary to read reviews about the company's work, because cheap services do not always provide high-quality results.

In the next video, see the video on installing automation on the swing gates.