Anaerobic sealants: properties and application

A variety of acrylic adhesives are anaerobic sealants. They are suitable for fixing and strengthening threaded connections and demonstrate high technical and operational characteristics. Let us consider in more detail this type of compositions.

What it is?

Anaerobic sealant is a polymer gel used for threaded seals, as well as providing its anti-corrosion protection. It provides absolute sealing of threaded connections, therefore it is used primarily in the military and aerospace fields. If we talk about domestic use, then this plumbing work is a network of water, gas and heating.

The polymer has a liquid consistency, thanks to which it manages to fill all the grooves and spaces of the working base. In the conditions of contact with metal surfaces in the absence of air, the gel solidifies, ensuring reliable sealing.A kind of sealant is anaerobic glue, the main difference of which is to ensure superstrong fixation.

This composition has increased strength and is suitable for compounds that are not subject to further disassembly.

In contact with air, the polymer does not freeze, so it is easy to remove excess composition from the surface of the parts. From the inside of the pipeline, they simply wash off with water. And inside the parts, in the place of the thread, the gel is polymerized, firmly grasping the elements and ensuring their tightness.

The principle of operation is based on the polymerization reaction and can occur exclusively in the anaerobic (airless) space. This process involves several steps. Primarily between the parts to be bonded, free radicals are formed. Further, the ions of metal surfaces trigger the polymerization process, as a result of which the sealant begins to solidify.

The gel is resistant to vibration and pressure, the influence of high and low temperatures and their abrupt change, aggressive substances.

It can even be used in drinking water taps.

Composition

The properties and consistency of the gel due to its composition.The basis consists of acrylic oligomers and monomers. Plasticizers and stabilizers, as well as the initiating system, are responsible for the appearance of certain product qualities.

The viscosity and tint of the gel depend on the concentration of the thickeners and pigments that make up the composition.

Advantages and disadvantages

Anaerobic sealants replaced obsolete gaskets and seals. They are not only easier to use, they also provide better fixation of elements. Through the use of polymer gel, you can refuse to use special keys and carry out the work, even without professional skills.

Sanitary anaerobic sealant also has the following advantages:

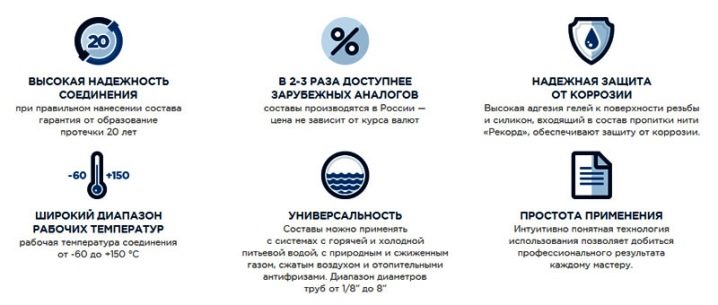

- wide scope of application, the ability to perform a huge range of work;

- mechanical stability;

- the convenient consistence in work providing also the best penetration and distribution of structure;

- the ability to select the composition of the desired viscosity for certain types of work;

- resistance of glue to temperature differences, wide range of operation (-60 ... + 300 ° С);

- composition vibration resistance;

- high strength properties - up to 39 MPa gas pressure and 58 MPa - liquid;

- resistance of the gel to the influence of aggressive substances;

- ease of use;

- fast freezing (depending on the type - from 5 to 6 minutes);

- economical consumption;

- environmental friendliness of the gel;

- affordability.

From the "minuses" can be identified too strong fixation of elements. Their separation requires preheating of the surfaces and tools treated with sealant. With excessive force, you can break the part. The sealant dries quickly enough, but only under the condition that the process takes place at a temperature of at least + 15 ° C.

If the temperature is below the specified, polymerization slows down, additional heating of parts may be required.

Kinds

Anaerobic sealants are divided into one- and two-component. The former are used in everyday life, the latter are used for the needs of industry and are characterized by higher technical properties.

Depending on the characteristics of strength indicators, the scope of use of sealants is determined.

In this regard, there are the following varieties.

- Low strength formulations. Suitable for fixing threaded joints, including those experiencing increased loads.

- Medium Strength GelsScope of application - strengthening of joints, performance of service works. The latter, as a rule, suggest periodic analysis of the compounds and their subsequent reassembly.

- Adhesives high strength. Provide a strong fixation, after which it is impossible to dismantle the threaded elements.

Depending on the ability to withstand high and low temperatures and the influence of aggressive media, the compositions can be divided into the following groups:

- sealants for sealing elements and components of the heating system, the maximum operating temperature is + 120 ° C;

- gels that withstand the effects of a wide range of aggressive substances with a temperature range of use in the range of -60 ... + 140 ° C;

- universal fast-hardening compounds, differing equally high adhesion to all types of surfaces.

Depending on the consistency, sealants are strong and medium flowing, flowable, non-flowing and pasty. Finally, the differences relate to the colors of the sealant.

They may have white, red, green, blue and some other shades.

Manufacturers

Today on the construction market there are many anaerobic sealants of various brands.

When choosing a specific composition, you should be guided by the following criteria:

- compliance of the sealant with the material from which the thread is made and its features;

- prescribed temperature conditions of operation of the composition;

- requirements for the type of joint strength.

Among the most famous, who deserve positive customer feedback, the following manufacturers should be highlighted.

- Loctite The manufacturer’s product range includes several forms of anaerobic sealants — liquid gels, sealing threads of similar effect, compositions designed specifically for gas pipes, etc. The products are notable for their reliability and durability. The cost depends on the type of gel. For example, for a tube in 50 ml of universal adhesive Loctite 577, characterized by a high rate of hardening, you will have to pay 1700-1750 rubles. For analogue low viscosity Loctite 542 - 50-100 rubles more.

- Anaterm. The products of this brand is also famous for its high quality, however, it is domestic, and therefore has a slightly lower cost. The manufacturer offers several modifications of the composition, which are suitable for fastening parts at the time of assembly and a more durable connection, to eliminate pores and small cracks in the threaded connection.Separately, you should select a line for steam lines and tools for the repair of components and mechanisms. Price on average ranges from 2400-2500 rubles per tube of 200 g.

- "Santekhmaster." A worthy representative of Russian-made anaerobic sealants used to grip and strengthen threaded and flanged connections provides anti-corrosion protection. The adhesive does not have an unpleasant odor, is easy to apply, tolerates pressure and temperature “leaps”, is resistant to chemical elements (including gasoline, antifreeze, alcohol), and is suitable for use in extreme conditions. The only inconvenience is the need to apply the composition by hand. In this case, prolonged contact with the skin can not be called useful. Available in tubes of 15 ml. According to the manufacturer, this volume is enough to handle 30 fittings with a diameter of ½ inch. The average price is 150 rubles per tube.

- Siseal. Medium strength sealer suitable for use in heating, gas and water pipelines. Cannot be used in systems characterized by increased oxidation. The color is white, the release form is tubes of 100 g each, the price of one is on average 900-1000 rubles.

- Permatex. Under this brand gels of increased strength are produced, which withstand ultra-strong vibrations and temperatures and are used for industrial purposes. Suitable for sealing flanges in pumping systems, gearboxes, cylindrical units.

- Tangit The tool is a universal paste for domestic use. Available in tubes with a brush, volume - 50 mg. The average price per item is about 550-600 rubles.

- Dirko. Sealant increased strength, thanks to which it has found application for industrial purposes, as well as car repair. One of the advantages of the composition is the possibility of applying the gel to moving parts without stopping the workflow. Suitable for use in extreme conditions, available in several versions. For domestic use, you can choose a heat-resistant universal sealant, all other varieties are more suitable for industrial purposes.

- "Catch number 3". It is an anaerobic adhesive for domestic use. Due to the uniqueness of its composition, it can be used for sealing systems and components of water and gas pipelines, heating pipes.The composition provides reliable protection against corrosion, suitable for the elimination of pores and small cracks.

Among other brands of sealants that deserve attention, it is worth noting the domestic "Unigerm" and imported compounds Abro, Quickseal, Uni-Fitt.

Application

As a rule, glue is sold in tubes equipped with a flat neck. Thanks to this, even for small threaded connections, it is possible to extract the required amount of sealant. The same neck, if necessary, it is distributed over the surface. Some manufacturers attach to the tube a small brush, which further simplifies the process of using the composition.

The procedure for using the gel is as follows:

- shake the package before use;

- open the tube and apply glue at the joints;

- fix the parts and hold them in this position for 20-30 seconds;

- eliminate any excess sealant by wiping the surface with a clean cloth.

In plumbing, as, indeed, in other areas, it is important to apply sealant from the inside and outside, ensuring a uniform distribution of the composition over the entire working base. Only in this case can we guarantee long-term and complete sealing.To obtain better fixing, work should be carried out on a dry and degreased surface. For these purposes, you can apply a solvent that should be allowed to dry completely.

The setting time of the sealant is usually 15 minutes. For compositions of different manufacturers, the time of polymerization can vary (from 5 minutes to an hour depending on the brand and purpose of the gel). The optimum temperature for work is + 15 ... + 25 ° С.

You can use the system in 3-4 hours, the final polymerization occurs, a day after application.

The sealant demonstrates its properties at pipe joints with a diameter of not more than 8 cm. Better adhesion is demonstrated when applied to rough than to smooth and polished surfaces. It is possible to apply over contaminated surfaces, but if possible, they are still better to clean and degrease.

If it became necessary to separate the parts glued with sealant, you should prepare special keys and a building dryer. The latter should be turned on and heated layer of sealant. After that, it will begin to crumble.When the threaded connection is released from the main mass of glue, the parts are disconnected using a plumbing key. If the further use of the parts is supposed and their fixation with an anaerobic sealant, the old composition layer can not be completely removed, but a new one can be applied on top of it.

You can find out how to use anaerobic sealants in the video below.