Features of butyl sealant

Construction and repair work can not be imagined without the use of sealant. In this article, we consider butyl sealant, its functional features, pros and cons, and how this product differs from its counterparts.

Specifications

Butyl sealant is a thermoplastic mass with a single-component structure, which is made on the basis of synthetic rubber called “polyisobutylene” - it is it that determines the special strength and strength of the material, as well as its specific consistency.

The composition shows resistance to bleach, and also does not react with acid-base solutions and many other chemical reagents. In its structure and technical-physical parameters, the sealant resembles volcanic rubber.

The main use of butyl sealant is the formation of the first sealing layer in plastic windows, it creates a barrier that prevents water and condensate vapors from entering the glass, and is also used as an additional material for their installation due to the fact that it effectively combines glass with a spacer frame.

Before work should pay particular attention to the working melting point of the substance, as a rule, this information is contained on the packaging, and on the parameters of the tank for loading the cylinder itself. If all these factors are taken into account correctly, then work with sealant will have no difficulty.

As already mentioned, the main active component of the material is polyisobutylene.which is a high molecular weight polymer with a chain-chain structure. Such a structure causes increased resistance to oxygen, as well as ozone and solutions of alkalis and acids. In addition, the substance is able to withstand the effects of permanganate and potassium dichromate, as well as other strong oxidizing agents.

Synthetic rubber does not swell, it does not dissolve in ethanol at all, retains its physical and technical characteristics in acetone and similar oxygen-based solvents, however, it quickly diffuses into aliphatic and aromatic hydrocarbon compounds.

The material is able to withstand prolonged heating, so it does not melt and does not change its consumer parameters. even with prolonged exposure to temperatures of 100 degrees, from higher temperatures when heated to 150 degrees and more acquires high plasticity, and at this point it can begin to form. In addition, the material does not change its performance as at temperatures as low as -55 degrees.

A distinctive feature of the substance lies in its water resistance and dielectric ability - by these indicators it is second only to polyethylene and polytetrafluoroethylene.

Polyisobutylene sealant has a low gas permeability, is not creeping and low strength composition.

Advantages and disadvantages

Like any other material, butyl sealant has its advantages and disadvantages. Let us dwell on them in more detail.

Of the benefits should be noted:

- high plasticity - thanks to which the joints and gaps of any shape are successfully sealed;

- vapor tightness - this prevents the formation of condensation and moisture on the double-glazed windows;

- the ability to repel water - so that the material does not form mold and does not multiply fungus;

- versatility - can be effectively applied on a wide variety of surface types (steel, aluminum, plastic, rubber and glass);

- environmental and chemical safety - the substance does not contain harmful and toxic substances, does not emit radiation;

- excess of the applied composition can be quickly and easily removed;

- has a long lifespan - retains its sealing properties up to 20 years;

- does not contain any volatile components in the composition;

- shows resistance to direct sunlight;

- has a wide operating temperature range from -55 to +100 degrees Celsius;

- different affordable price.

The disadvantages of the composition:

- has a narrow scope of use;

- only available in black or dark gray;

- at sub-zero temperatures, the tensile strength of the material decreases.

Field of use

The main scope of the use of butyl sealants is the production of glass. With this material all the gaps and joints that appear in the manufacturing process are sealed. With its help heat-insulating panels stick together with each other, and also condense the operating air ducts and central airs indoors.

Some use such compounds to ensure the greatest tightness of various vessels and containers.

Polyisobutylene-based sealants often serve for the production of electrical insulation coatings and elements of anti-corrosion systems, as well as for the manufacture of chemical equipment and pipelines of various types.

Separate compositions are the basis for the preparation of adhesive solutions, as well as for the manufacture of moisture-resistant fabrics.

Rubbers with a molecular weight of from 10 to 25 thousand g / mol are used as thickeners for lubricants and additives.

Separate versions of sealants are used to work with automotive glass and auto-optics.

Species

There are several varieties of butyl sealants.

"Vikar" - This is one of the most popular materials based on synthetic rubber.It has many advantages over other compounds, namely: it exhibits qualities such as high elasticity, strength, excellent adhesion with metal, tile, ceramics, PVC, natural stone and such porous bases as concrete.

"Vikar" is a plastic homogeneous mass consisting of bitumen, rubber, filler, technical additives and solvent. Due to its composition, the material exhibits special resistance to UV radiation and temperature fluctuations.

With the help of this composition produce such types of work as:

- reliable sealing of joints, as well as connecting joints in order to increase the heat resistance index, while its use is allowed for both internal and external works;

- sealing joints of plastic panels;

- sealing of ventilation and air conditioning systems, as well as roofs and chimneys;

- reinforcement of seams in vans and metal bodies, which is made in order to increase protection against the risk of rust and subsequent destruction of the material.

Sealant "Vikar" is implemented in tubes of 310 ml in dark gray and black versions or in the form of a tape, which looks like a two-sided moisture-resistant self-adhesive material.

Such tape is not necessary to heat up before use, as a rule, a similar modification of the sealant is used when working with panels, stained glass windows, ventilation systems and hard roofing.

It is often purchased for mounting insulating components and sizing cloths, in addition, instead of a cushioning material in the construction of sewage and plumbing systems.

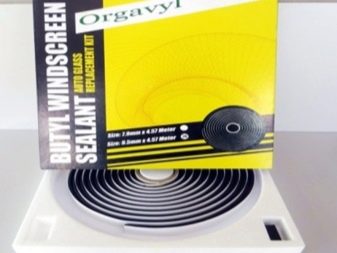

Orgavyl Sealant - This is another quite popular among consumers butylene type of sealant, which is produced by the same American company. Its scope of use is slightly different - it is made to work with car headlights and glass.

This type of sealant does not form cracks, it does not dry out and at the same time forms very high-quality waterproofing and sealing of auto-optics. Such a composition can be used repeatedly, enough for the simplest reheating.

Orgavyl is resistant to antifreeze and all sorts of solutions of the oil structure, it is highly tacky, has no odor, and does not stain car parts, and at the same time prevents the glass from sweating in the car.

To exploit the sealant, it’s enough to do a few simple steps:

- completely clear headlights;

- put on her tape-sealant, after slightly stretching it;

- heat the material with a hair dryer and press it tightly to the glass.

This sealant is available in tape form in several sizes.

The reliable composition of "Hermabutil" is also very popular with consumers.

Butylrubber sealant is a high-quality and practical material. They are low cost and sold in any hardware stores.

About Orgavil butyl sealant for assembling car headlights, see the following video.