Threaded Sealants: Types and Purpose

There are many types of thread sealants. They all have the same purpose: complete sealing of pipes. However, in different cases, each sealant works differently, and this must be taken into account.

Purpose

Many people mistakenly believe that the use of sealant is a purely voluntary matter. After all, it is possible to tighten the nuts tightly without any problems, and then to operate the plumbing equipment, making sure that nothing flows anywhere. However, there is no need to flatter yourself.

Threaded connections are not monolithic at all. Indeed, at first they will keep well, but then a leakage will inevitably arise.In the case of plumbing or plumbing, it is not as scary as if a leak occurred in a gas pipeline.

The same applies to the pipes through which diesel fuel is supplied: at least a strong unpleasant odor is guaranteed.

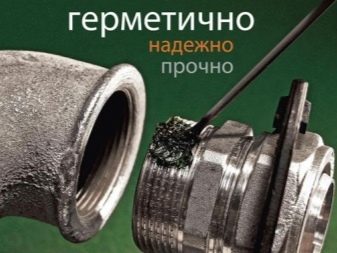

To avoid such troubles, it is recommended to immediately seal the threaded connections. In addition, it is necessary if gas or water is planned to be supplied under high pressure. Also, high-quality pipe sealing guarantees sealing of the joints, which means that they will last longer.

There are special sealants with which you can seal the fittings. Others are designed to work with pipes exposed to high temperature.

This is necessary when working with pipes of the heating system: batteries, radiators, "warm floor".

Characteristic properties

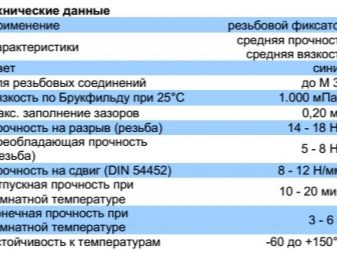

All sealants have a special set of qualities that you need to know and be able to evaluate:

- Flowability This refers to the viscosity of the sealant. So, if you need to seal a small gap, it is better to choose a gel or paste. Their texture is perfect for this. If we are talking about sealing a large gap, then it is necessary to purchase the most liquid composition.Remember that the larger the gap, the thinner the sealant should be. So he will be able to fill all the cracks, tightly fastening the pipe connection.

- Temperature. The working temperature range of sealants is not infinite. At a certain temperature, they will no longer firmly fix the pipe, which can lead to leakage. For most samples on the market, the temperature range is 200 degrees - from -50 to +150. Usually this is more than enough. If it is necessary to seal the pipes through which the colder substance flows (for example, pipes for liquefied gas), then it is necessary to pay attention to specialized samples.

- Strength. Under the strength means what effort must be applied to separate the joint. If a low strength sealant was used, it would be sufficient to apply strong force with your hands. The fitting, sealed with medium strength sealer, can be unscrewed only when using additional equipment. Sealant strong fixing impossible to dismantle: the joint will have to break.

- Polymerization rate. On the packaging it is indicated how long it takes for the sealant to fully harden.You can start using pipes only after this time has elapsed.

- The maximum diameter of the thread that can fix. It just so happened that not all sealants work on all pipes. In the case of an improper composition, the useful effect of its use is reduced to zero.

- The possibilities of use. Some sealants are not suitable for fixing pipes that carry drinking water, since they emit toxic compounds into the water. Need to pay close attention to this factor.

Advantages and disadvantages

The use of various sealants for threading has its advantages and disadvantages, which must be borne in mind before proceeding with the sealing procedure.

The advantages of using threaded sealant are great:

- It retains its properties, despite significant temperature fluctuations. This does not affect the tightness of the joint - it remains unchanged.

- Resistance to mechanical stress. Accidentally unscrew the nuts will not work. To do this, you will need to make significant efforts. If water is supplied under high pressure, then nuts in the pipes without uncooling can unwind due to vibration in the pipes. Here this will not happen.

- The ability to penetrate the smallest cracks and crevices.Due to this, a high adherence of parts to each other and, consequently, complete tightness is achieved.

- Low consumption. Very little material is needed for threading, so one bottle bought will be enough to handle all the pipes in an average apartment.

- Ease of use. Intuitively, how to use a sealant. Also attached to it is a detailed instruction with all the characteristics, precautions, recommendations for use.

In addition to all the listed benefits, there are sealants and cons:

- In order to disengage the pipes (for example, for repair), it is necessary to exert excessive efforts. Sometimes dismantling is not possible at all, because the sealant was chosen strong fixation. Then the pipe becomes monolithic. The only way out is to break the pipe.

- Compared to traditional materials, sealant is quite expensive. If you take the tool from a good eminent manufacturer, the price tag will be even higher.

- It will be necessary to wait until the sealant dries completely. The hardening time depends on the specific brand.However, as long as the joint is not “grabbed,” it will not be possible to use the pipe.

As you can see, there are only a few shortcomings; therefore, the overwhelming majority of professional builders agree to use only sealants of industrial production for sealing the thread, and not improvised materials that came to us from the Soviet Union.

Types and characteristics

In order to seal the pipe connection properly, many materials are used today. Some of them have long been familiar to everyone, others have appeared only recently. However, each of them has advantages over other means, and you need to know about these advantages.

Linen thread

The use of thread from flax is the oldest way of sealing the thread. The only advantage of this tool is its low price and constant availability. Even if any other sealants are not available, the linen thread will be accurate.

But the material has many shortcomings:

- It is difficult to lay on the thread. If you do not have the skill, then you can hardly do it right the first time. If a mistake is made during the winding, then this joint will quickly unwind, reducing to no. All your efforts.

- Small operating temperature range.Linen threads practically do not tolerate heat, so they can not be used to isolate batteries and radiators. They will quickly collapse, leading to leakage.

- Hydrophilicity Linen thread absorbs moisture well, as a result, in the process of work it greatly swells. This may cause the pipe connection to burst. Such cases are possible when it comes to pipes made of fragile materials, such as aluminum. However, the flax thread is still used to isolate those pipes through which water does not flow.

Teflon or plumbing thread

Teflon or plumbing threads are in many ways similar to those of flax. Likewise, there is a need for proper winding, but this is the only drawback they inherited from the natural “predecessor”.

Teflon threads are impregnated with special compounds that make them versatile. They function well both in the isolation of water pipes and gas or other. Compared with the previous case, the sanitary thread ensures a good fit, does not break for a long time. It can withstand high temperatures, and nothing will happen to it.

Teflon threads are completely safe. Nothing gets into the pipeline from them, so they are suitable for use on pipes with drinking water. However, it is better to clarify this point further.

Some cheap samples are intended solely for technical use.

FUM tape

FUM tape is one of the most popular options, as it is easy to use and has a low cost. All you need to do is to wind a piece of tape on the thread, and then carefully tighten the nut or fitting.

However, the main plus tape is not in it. It does not affect the thread. If other materials break up or stick, then the FUM tape is easy to remove completely by simply unscrewing the thread. At the same time, the tape is completely safe and excellent for sealing water pipes.

Unfortunately, the tape can not fix the connection, as they say, tightly. With vibrations or mechanical effects, the joint will weaken until inevitably a leakage occurs. The only means of prevention - periodically tighten the nuts. In connection with this drawback, do not use it to seal the joints on those pipes,along which water goes under great pressure.

Non-hardening

This type is relatively new for the Russian consumer. These compositions are produced in the form of a paste, with which you need to process the thread well, and then simply tighten the nut. It is also easy to unleash it in the future.

A viscous substance does not stick the pipes, but simply fills the gaps and gaps, preventing water from leaking out. The composition is absolutely harmless to humans, so these sealants can be used in works with water supply.

Do not use sealant-paste in cases where the water supply is under high pressure. Then the water will force out the sealant and a leak will occur. Unfortunately, there are no means of prophylaxis here, so you just have to give up using such a remedy, choosing some other, more suitable option.

Solidifying

Such substances have high strength characteristics. Sealant-lock dries long enough. Time may vary considerably from manufacturer to manufacturer. However, this is the only drawback of such products.

Applying and twisting this sealant, you must wait the time indicated on the package.before embarking on testing and active operation. This is especially the case when water is supplied under high pressure. It is worth noting that the sealant perfectly tolerates prolonged exposure to water under high pressure, since it is almost impossible to force out after it has dried.

On the market there are funds with some degrees of fixation.

It depends on the degree of how exactly if necessary it is necessary to unwind the pipe: just put more effort or break it.

Anaerobic

Today anaerobic fixers are the latest development, quickly gained recognition. They are suitable for use by both amateurs and craftsmen. Sold in convenient tubes of 250 ml and are suitable for long-term storage.

The principle of operation of the anaerobic sealant is as follows. In the open air, it retains a liquid consistency, so it can be easily applied to the thread, without fear that it will “grab” ahead of time. After the nut is tightened, the chemical process begins, the sealant crystallizes, becoming a plastic glue and making the joint completely monolithic.The total reaction time takes no more than 3 hours, after which you can begin full operation.

Dismantling is carried out with the help of heating: you need to warm up the joint properly, after which you will be able to unscrew the nut.

This method does not work with sealants strong fixation.

Sealing gel

Threaded sealants from this category are rarely used in everyday life. Basically, they have found application in the automotive industry, as it is convenient for motorists to carry with them a sealant in the form of a gel, so that if necessary it will be possible to quickly repair a broken part.

The main purpose of the gels - not sealing, but the strengthening of the joints. They make them more durable and resistant to vibrations and mechanical loads. That is why many are faced with such difficulties when naively trying to unscrew any bolt on the engine: even at the factory they are treated with a sealing gel.

The only way to cope with a joint treated with a similar agent is to heat it well.

Otherwise, you can waste your efforts, without having achieved the desired result.

Colors

Threaded sealants are available in a large assortment of colors.General concepts that means a particular shade does not exist. It all depends on the manufacturer. In this regard, it makes sense to consider the color of sealant in relation to the company that released it.

Along the way, the manufacturers themselves will be considered.

- Green. The most popular is the green locking gel for carving from the Russian manufacturer SantehMaster. It provides the weakest fixation, and therefore it is possible to unwind the junction with an ordinary key.

Green sealant has a limited range of action. It is suitable only for processing pipes whose diameter is less than one and a half inches.

The average cost of this tool is 410 rubles per tube of 60 g.

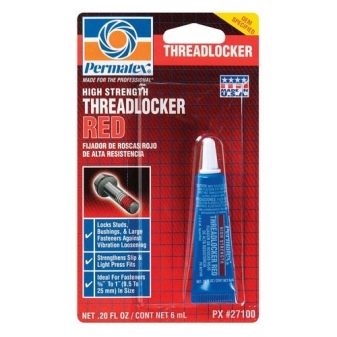

- Red. This gel is produced by the Russian company StopMaster. It differs setting time. So, if on average it takes about 2 hours to set, then this tool will polymerize in 5 minutes. Sealant is classified as anaerobic.

Most similar option is suitable for pipes made of ferrous metal, for example, cast iron. The temperature at which the sealant does not lose its properties - from -60 to +150 degrees.You can work with it at a temperature of +5 degrees.

As in the previous case, the average cost is 410 rubles per tube of 60 g.

- Blue. The Russian manufacturer SantekhMaster claims that this anaerobic gel has been specifically designed to seal sanitary equipment. Sealant refers to the universal, that is, it is suitable for plastic and metal pipes. The polymerization process takes up to 15 minutes, thus it remains possible to correct the joint.

Use sealant possible if the temperature exceeds 15 degrees. Otherwise, there is no guarantee that the subsequent work of the lock will be as efficient as possible.

The price for a 60 g tube is 410 rubles.

- White. The German company Loctite offers white sealants, mainly designed for sealing plastic pipes. However, these silicone sealants can also be used with small diameter metal pipes.

The maximum diameter of the pipe that can be processed is 3 inches, and the joints can be made from pipes of the same material or from different ones. Optimum tightness is achieved at a humidity of no more than 40%, while the temperature of the air or surface does not affect the polymerization.

The average price for a 100 ml tube is 685 rubles.

- Orange. This color has anaerobic gel-sealant from Scotch-Weld. Mostly it is used in the automotive industry, as it firmly glues parts. In order to further destroy the joint, you need to use a strong heat, otherwise the pipe will have to break.

- Yellow. Anaerobic adhesive sealant from QuickSpacer is only suitable for sealing metal pipes or fittings. The already low rate of its polymerization increases if you use this option with iron alloys.

It is possible to work with this sealant at temperatures from +10 to +40 degrees. In addition to the sealant itself, it will be necessary to purchase a spray activator from the same company, otherwise the retainer will not “grasp”.

The average price is 420 rubles per tube of 50 grams.

How to choose and apply?

In order to make a choice, you need to familiarize yourself with the technical parameters of the version you like. Of particular importance is the pressure it can withstand and for which diameter of pipes it is suitable. See also what you can use with it. Some products cannot be used with water, some with gas, and some with fuel materials.

If the application of sanitary tape requires special skills, then the treatment with anaerobic or other liquid or gel-like sealant is not difficult.

Stages of work:

- First you need to clean the thread well, remove dust, rust. If there is a lot of rust, it is allowed to use a metal brush to clean it.

- After that, you need to degrease the thread. It is necessary to degrease not only one of the pipes, but both. For degreasing, you must use a specially designed tool, and if it is not, then acetone will do.

- The sealant is applied with a thick layer to one of the parts, after which the joint is joined. Those remnants that come out from the inside, wash away with water. Do not rush to also wash away the extruded from the outside: they can be used for other threads.

To transfer the excess, you can use a plastic stick. Pre-need to warm it up. Then the sealant does not “grab” ahead of time. Do not be afraid that the transferred composition will not be of sufficient quality. As practice shows, the properties of the anaerobic gel (and this option is most preferable) do not change due to interaction with air.It begins to polymerize only in contact with iron and in the absence of air. In no case do not use metal objects for transfer, as the sealant may react with them, and its fixing properties will deteriorate.

Dismantling

In each case, the dismantling is carried out in different ways.

If the sealant was chosen weak fixation, it will be enough to unscrew the nuts with a key.

The medium fixation sealer needs to be slightly heated, and then apply a little effort, spinning the connection with the key.

Sealant strong fixation, you can try to warm up well, then unleash.

If this did not help, then dismantling is impossible.

After all the nuts have been removed, it is necessary to remove the sealant from the thread. This should be done carefully, trying not to damage the thread itself, otherwise it will not stop. Water in this case is not an assistant, but you can try to use solvents.

On the package with your sealant should be recommendations for its removal from metal or plastic. If you read them, you can save a lot of time instead of guessing and putting experiments.

You can find out how to apply thread sealant in the video below.