Features sealants "TechnoNIKOL"

All sealants of the TekhnoNIKOL brand are manufactured on the basis of one-component and two-component compositions. Due to this content, they acquire high quality and constant elasticity. The most popular of them are polyurethane-based sealants, which protrude as an elastic and viscous mass. When such a solution is applied to the surface, it will polymerize, forming a high-quality compound of materials.

Special features

Today, craftsmen pay much attention to the quality of the tightness of joints, as well as different types of joints when assembling structures made of various materials. For such purposes, a popular compound is a sealant based on polyurethane "TekhnoNIKOL", which is a medium modular.This feature makes it possible to apply it in a wide variety of fields, for any kind of material. It creates a high-quality and durable compound that does not let moisture through.

This type of brand composition can be used for such purposes:

- for elastic sealing of compounds of a structure that is made of light metal or steel;

- it can be used for high-quality sealing of tanks, containers and other similar objects;

- they are filled with vertical and horizontal joints of the compensation type;

- this composition is often used for grouting joints after laying ceramic tiles, cable shafts, concrete floor slabs;

- used to obtain waterproof connections in the construction industry, as well as for the purpose of compaction in industry;

- such a composition can be used as a glue for the roof.

The main feature of this material is the fact that it can be used not only for domestic needs., but also for industrial facilities. This is due to the fact that such a composition perfectly connects the building elements of any type of material.It also possesses resistance to external aggressive action, elasticity, makes it possible to paint treated surfaces to the color of the base.

It should also be noted that the use of sealant "TechnoNIKOL" does not allow moisture to affect the design.

The features include the following parameters of corporate sealant:

- increased elasticity after solidification of the composition;

- excellent adhesion with any type of surface;

- resistance to moisture;

- the rate of hardening and drying, if you use the composition correctly;

- resistance to different temperature indicators, for example, the composition is able to withstand temperatures down to -45 degrees, but the treatment of the base itself should be carried out at a temperature not lower than -10;

- most sealants have a negative effect on direct sunlight, and the “TechnoNICOL” composition is not afraid of this effect;

- after applying a layer on the surface, the composition does not shrink;

- the material is safe, does not emit harmful substances into the environment, and does not affect the human body;

- consumption of this material is economical;

- The compound with this compound is durable and reliable;

- The peculiarity of this material is the possibility of dyeing it after drying, but the paint should be water based.

Due to this number of features and advantages, TekhnoNIKOL sealant is considered universal, which makes it popular among consumers. There are drawbacks, but they concern hand protection and heat.

These nuances do not affect the quality and reliability of the sealant.

Kinds

The manufacturer TekhnoNIKOL manufactures an extensive range of sealing compounds, which have their own characteristics and various technical characteristics. Consider the main types of sealants.

Composition based on polyurethane

One-component polyurethane material is the most popular. It is based on the fact that it has excellent adhesion with any type of surface. For example, such a sealant perfectly glues wood, metal, concrete, brick, ceramics, plastic and other types of materials. Such a connection is of high quality, reliable, and does not respond to moisture and vibration. When exposed to moisture, this material acquires additional strength.It can be used at air temperatures from +5, but not higher than +30. No less effective and practical is a two-component composition based on polyurethane (2K).

When the composition hardens, it is able to tolerate temperatures from -30 to +70 degrees. As for the use of such a sealant, before starting work it is necessary to clean and then dry the surface. It starts to harden after 2 hours, and full hardening takes place with the calculation of the day for a 3 mm layer of material.

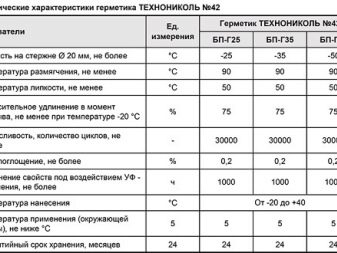

Based on bituminous polymer

This tool is labeled №4. The basis of this material is bitumen with an admixture of artificial rubber and mineral components. This two-component sealant is used to seal the joints of asphalt, concrete and on airfield pavements. It differs fast freezing. When dried, this sealant does not shrink, but remains elastic.

Bitumen-polymer composition is produced in 3 types:

- BP G25;

- BP G35;

- BP G50.

The first type is used in the environment where the air temperature can not fall below -25 degrees. BP G35 is used in places where the temperature does not fall below -35, and BP G50 is used where the temperature indicator can fall below -42 degrees.

Mastic based

This sealant is available with the marking number 71.As a rule, sealing mastic is used as a roofing material that can withstand about 20 kg. They can repair the roof or glue the elements of the roof. He also has excellent adhesion to the concrete surface and metal. Such a sealant does not pass water and is resistant to high temperatures, which allows it to be used as a membrane.

Silicone Based

Silicone-looking materials are used during construction. It is recognized as a universal compound that is suitable for high-quality sealing of surfaces, and therefore relevant in various fields. After application to the surface, it quickly hardens. When water gets on it or moisture influences, the structure becomes even stronger and more elastic. This is a popular product that is sometimes used as an analogue of a rubber seal for various types of structures, for example, for PVC.

The rate of solidification of such a sealant is calculated taking into account the 2 mm layer for 1 day.

Colors

If we talk about the colors of sealants, which are produced by the manufacturer TekhnoNIKOL, they can be gray, white and black.So, the composition of black color is often used for sealing gaps, gaps and joints between structures. Also, using a similar sealant, heat-insulating panels and air-conditioning systems are glued together. The shelf life of the composition is about 15 years. The main disadvantage of this material is its dark color, due to which it can not be used in all cases.

Gray and white sealants are popular today. Such compounds are the best option for use on any type of materials. They do not shrink when cured, have a high level of elasticity, are resistant to oil, and can also withstand aggressive environmental influences. Such thiokol-based sealants are manufactured, which is why they can be used in all weather conditions.

The main feature of the white sealant is the fact that after hardening it can be repainted to any desired shade, but the paint should be water-based.

Consumption

Consumption of materials produced by TechnoNicol is very economical. It should be noted that this parameter depends, first of all, on what size of the seam will need to be sealed.For example, a minimum package is enough to “close” a joint of 6 mm in width and 3 mm in depth. Such cracks are often found in bathrooms. The consumer will need about 25 ml of sealant to carry out all the necessary types of work.

There are large packages, for example, the composition of PU 600 ml. Such packaging is enough for a long time. With it, you can correct many shortcomings, for example, slanting seams, semicircular gaps between the bathroom and tile, as well as any other problem areas.

Tips

The manufacturer TekhnoNIKOL produces various sealants, therefore the scope of their use is very wide.

These compounds are suitable for:

- repair work;

- used instead of a waterproofing layer;

- used to eliminate the empty gaps near communications;

- to align the seams when installing plastic structures;

- These types of sealants are used for a variety of industrial applications.

Experts recommend using the material in this order:

- need to mix the material well;

- it is also necessary to clean the surface from dust and dirt, since such factors negatively affect the quality of the coupling of the composition to the surface;

- it is important not to forget to degrease the material;

- in that case, if the work must be carried out at a minus temperature, the sealant must be left in a warm room for a day;

- the composition is applied with a rubber or iron spatula, but it is necessary to wear protective equipment for hands and possible places where the composition may fall;

- It is not recommended to add a solvent to the composition, although this will facilitate the work process, but will negatively affect its quality;

- when processing, you need to monitor the gaps (if there are gaps in the seam, this will affect the quality of the sealing);

- It is recommended to follow the instructions for use, which is on the package with a sealant.

The compositions of "TechnoNIKOL" can be used at low air temperature, as well as in places of high humidity.

For information on how to properly seal the seams and abutments on the facade, see the video.