Choosing a pneumatic gun for sealant

Currently, the stores offer a large selection of pneumatic guns for sealants. They are the best option when thinking about high-quality repairs in the apartment. Each of them can make the workflow easier or more difficult if you make a bad choice.

This tool is simply necessary for accurate and uniform application of sealant for any repair work and is irreplaceable, as it allows to fill any gap, even in a difficult-to-reach area.

Tool description

Pneumatic gun for sealant consists of two words. The “pistol” is used due to the principle of operation, since the mixture is released by pressing on the trigger, and the first part of the word “pneumatic” means that the mechanism operates by compressed air.This gun is used to perform a small but serious work, so it is great for workshops that provide commercial services, or self-repair apartment or a country house. The tool works at the expense of air entering under pressure from the compressor. Because of this, it is impossible to move around the room during work, you have to do it in one place.

The composition of silicone, polyurethane or acrylic is served after lowering the handleThe force of the piston pressure can be controlled, so that the mixture will be applied neatly and economically. Pneumoguns exist only closed type. A closed case is a container that is shaped like a pipe or a balloon. Due to this, they are firmly fixed and do not allow the substance to penetrate into the device. Piston pneumatic gun is used to apply a suture, glass or spray sealant.

Spheres of application

Pneumoguns are versatile tools that are used not only for applying sealant, but also for silicone with mounting foam. These compounds are necessary to perform any repair or construction work in everyday life.Hermetic substances are produced in liquid form, but freeze rapidly in air. The resulting mass fits tightly to the surface, is not afraid of moisture, temperature changes and the influence of ultraviolet radiation.

Hermetic substances are used for such purposes as:

- hide minor flaws made in the performance of various works;

- protect joints between different surfaces from moisture.

They are widely used in the repair of machinery, construction and industry. However, without a special construction mounting gun, their use is impossible.

How to choose?

To make a choice of equipment is easy, you need to first examine its structure. The pneumatic gun for hermetic mixtures is a professional and almost autonomous tool. When choosing it, you first need to look at comfort at the time of use, ease and reliability. And also inspect all the buttons, pistons and body connection. Next, you should check the threads of the nozzles, the return of the buttons and the ability to control the pressure force of the piston. And also you need to look at the work of the trigger, because pressure should not feel the tension.

Choosing a gun, you should pay attention to the volume of the container for the sealant.Simple tools can only work with small volumes. The most common are cylinders of 310 and 600 ml. More expensive equipment is intended for more large-scale and professional work. It can be refilled in containers of 900 ml.

It is best to choose models of famous and proven brands. Of course, they are more expensive, but the quality pays off, especially if large amounts of work are planned.

Among the popular companies that produce air pistols, it is worth to highlight a few.

- Ani Company produces excellent piston air pistols from good materials, which ensures a durable and high-quality result. The models of this company provide for the regulation of pressure up to 8 bar, which allows for the most smooth flow of the mixture. Produce models for spraying and seam sealants.

- Wilton Company also creates durable tools that are reliably constructed. They are made of lightweight aluminum and high quality plastic, materials are used that are resistant to the influence of popular solvents for cleaning tools.

- Company Workman. The supply in the tools of this company is carried out smoothly and continuously, which results in an even seam. The adjustment mechanism works simply and safely. Models are made of lightweight aluminum and plastic, and there is still the possibility of buying additional attachments.

Method of application and operating rules

Hermetic products are available only in specialized plastic and metal cylinders, because in contact with air, they soon dry out and become unsuitable for further use. It is difficult to get the mixture, because it lends itself only at constant pressure on the lower piston. Therefore, a homemade homemade tool will not bring special benefit and you will have to purchase specialized equipment, for example, an air pistol. Before performing work, it is necessary to prepare the surface using the instructions on the packaging of the material. Remove the old coating and thoroughly clean everything from its crumbs.

Then it is necessary to degrease the surface and treat it with a primer. Use a gun must be strictly following the rules of safety.All kinds of sealant guns have a standard method of use.

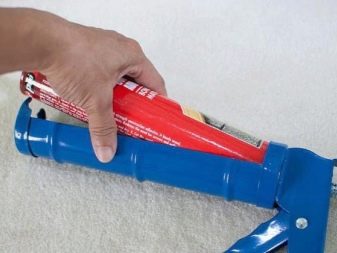

Refueling and use of the tool is as follows:

- you must first remove the stopper cover from the back;

- remove the plug in front or punch it with a sharp object;

- remove the piston, for this you need to hold the knob and press the trigger;

- then it is necessary to insert the cylinder into the container, push the piston up to the stop and fix the mechanism;

- install a pre-cut cone nozzle;

- perform work by squeezing the mixture by pressing the trigger and filling it with seams;

- after use, unscrew the piston and remove the container, after which it can be closed with a tip so that it can be used again;

- clean the gun with a solvent.

Some professional models need to be filled with a mixture. This process is similar to filling medical syringes with drugs. Sealant is drawn into a special cavity, the opposite action of extrusion. This procedure is always detailed in the equipment manual. Some companies even attach illustrations with its description.

To perform the perfect seams, you must use the following tips:

- The cylinder cap should be cut with a stationery knife at an angle of 45 °, in which case the diameter of the hole made will coincide with the size of the seam;

- to apply the mixture evenly, keep the tool at the same distance from the surface;

- you should not rush to leave empty areas;

- You can pre-paste the surface on both sides of the seam with masking tape;

- for a corner seam, it is better to wet the surface from the sides with soapy water;

- to smooth out the applied sealant if necessary, and the mixture does not stick to hands, it can also be wetted with soapy water; This method can remove material leaks.

Safety regulations

The use of pneumatic equipment obliges to comply with safety regulations. When using a tool and applying a sealing agent, protective equipment such as glasses, gloves and protective clothing should be worn. Before removing the applicator, you must not forget to disconnect the air duct. Using a pneumatic gun, you need to monitor the installation of the cap, it should fit snugly.After work, it is imperative that the equipment be cleaned using special cleaners, which the sealant manufacturer will recommend. However, do not completely immerse the gun in cleaning agent.

Advantages and disadvantages

Pneumatic gun has many advantages. It has a low consumption of the mixture due to the high precision of the seam. Work does not require electricity and expensive batteries. Ease, speed of application of the material and pressure control - all this allows you to do a lot of work in a short period of time. The tool does not create percussion and whistling sounds, it works silently.

The power of this type of equipment is higher than that of others. It works with different types of consumables produced in tubes and processes the seams with higher quality. It is an excellent choice for sealing glass. However, this type of tool has drawbacks. The main problem of the equipment is the lack of portability - it is necessary to perform work without departing from the place. And also to the disadvantages is its relatively high price compared to other types of pistols.

Cost of

Production of pneumatic gun for hermetic mixtures is more complicated than that of other models, as a result of which its price is also higher. Its cost depends on the volume of the mixture and the company producing it. The more famous it is, the more expensive the tool. Air pistol on average costs from 500 to 800 dollars, but there are more expensive models. The highest rates reach from 2000 to 3000 dollars, however, the overpayment is obtained not for the brand, but for a longer service life, because such models work from 3 to 5 times longer. For example, the professional tool of Soudal company, calculated on the volume of the sealing mixture in 600 ml, has a cost from 10 000 to 11 000 rubles.

Reviews

Pneumatic is the most popular type of equipment based on the statistics of sales of building stores. After examining the reviews of customers and professional craftsmen, it is possible to judge that sealant spray guns are considered very convenient for large and small construction. A tool for suture sealing can be used on various surfaces, from wood to double-glazed windows. And also the ease of doing the work with their own hands is commended.Due to this, it is not necessary to contact the craftsmen and call the workers, and the quality will not suffer from this at all.

It is also estimated that the valve does not allow the excess mixture to flow out, which is why material is being saved. Separately, the model designed for 600 ml, as they do not weigh down the weight. Hermetic mixture is enough to handle a large number of cracks and cracks.

Reviews about the material are opposite. It is believed that tools made from a combination of plastic and aluminum are practical and convenient, however, others believe that the metal in the case is superfluous.

In the next video you will find a review of the gun for the sealant company Licota, designed for hard and soft tubes.