How to choose a needle roller?

The roller is widely used in modern construction for painting and plastering and finishing works and has variations. The needle roller is the same roller tool. This roller is indispensable for arranging self-leveling self-leveling and polymer concrete floors, it is needed for processing gypsum and cement mortars, it helps when bending gypsum boards and removing the wallpaper manually.

Why do you need?

In the process of repairing the floor, a special mixture is prepared. In most cases, when it is mixed, air bubbles form, which can become a serious obstacle to the performance of quality work. If they are not removed from the solution in time,after drying, the screed will have micro-voids. Such deformations will further lead to surface irregularities. To serve such a floor will not be long.

Needle roller is indispensable for removing air from a liquid polymer or concrete solution. The cylindrical base of the roller consists of a handle and a substrate, which is covered with a needle-shaped material. The handle, in turn, is metal, plastic or wooden. Rollers made of metal are heavier, they are strong and durable, convenient for bending drywall, working with old wallpaper. Often, manufacturers equip such products lengthened handle.

How to use?

With the help of the needle roller, you can easily bend the drywall and give it the desired shape. For these manipulations, it is better to choose a roller from plastic material with steel needles. The technology is as follows: it is necessary to wet a sheet of drywall from the side on which it is planned to bend it. Then it is necessary to walk on the surface with a needle tool and make punctures with a diameter of 2 mm, after which the softened material will remain.The longer the needles, the more moisture will penetrate into the surface structure, the easier the drywall will bend.

To remove old wallpaper, you must first moisten the wall covering with water.and then carefully remove from the wall with a needle roller. This process is quick and easy. The needle roller is suitable for removing various wallpapers (paper, vinyl, non-woven, textile and others). In the processing of self-leveling and concrete coatings, the needle roller is used to remove oxygen bubbles and smooth the fill.

To eliminate voids, it is necessary to roll the roller intensively on the surface of the screed, which is already distributed over the floor.

Before rolling with a needle roller, level the floor with a trowel. Rolling is done without pulling the roller out of the mixture for 15-20 minutes. Time may depend on the composition of the mixture, before starting work, read the instructions in advance. It is necessary to work evenly and roll without pressure. It is better to move on special spikes for shoes, so as not to deform the new floor.

It is advisable to treat the floor in this way at least three times. Such pumping reduces the porosity of the mixture, prevents its deformation,what is especially important for rooms in which it is supposed to place industrial machines, massive objects and furniture on a floor. After the work is recommended to thoroughly clean the roller from dirt and dry.

Needle roller for flooring is widely used.It is a multifunctional and useful tool. All of the above manipulations you can perform independently, without invoking the wizard, which will save time and budget. In today's market there is no replacement for the needle roller, its use simplifies the process of floor arrangement and provides a guaranteed result. However, do not rely on only one tool. A good result involves a preliminary preparation of the base, the use of high-quality mixtures and materials, following the instructions. It takes sufficient time to dry the floor.

Tips for choosing

Finding a needle roller today is not difficult; choosing a suitable and high-quality tool is a matter of responsibility. Needle rollers are presented in hardware stores, markets, Internet sites. Needle rollers were used in the field of beauty and health.An example of this is a magnetic or special needle roller for massage treatments. It is important not to confuse these products.

Construction magnetic brushes also exist, but they are designed to clean particles from the surface of the floor or sandy surfaces. They are quite bulky, they are produced in the form of trailers or versions for manual rolling. When purchasing a conventional needle roller, you must consider the following features:

Manufacturing material

Material production affects the service life. The tool from metal more strong and durable, it is worth giving preference to it. Plastic over time becomes useless.

Roller width

The width of the roller, which varies from 150 to 600 mm. For a large area it is more practical to buy a wide roller, the narrow model is convenient for processing narrow niches and hard-to-reach places. For the treatment of drywall suitable roller of any width, for removing the wallpaper, you need a medium (400 mm) or maximum width (600 mm).

Needles

Needle clamping tools have needles from 8 to 34 mm long. This parameter is especially important if the tool is purchased for processing the floor.The thicker the tie height, the longer the needles should be. They will penetrate deeper into the solution, which will ensure work efficiency and the desired result.

There are needles of several forms: sharp cone-shaped, spherical and drop-shaped. Masters believe that spikes in the form of droplets are less effective. Sharp needles are used for more viscous mixtures, for example, based on epoxy resin. These mixes need to be pierced to remove air pockets. For a liquid self-leveling solution, spikes with spherical tips will do. The length of the needles is better to choose a little longer than the thickness of the poured floor.

If the needles are too short, the body of the roller will come into contact with the surface, create tension and dislodge the solution. As a result, there will be irregularities. Long spikes picked up incorrectly will create more bubbles and splash the mixture. It is important to choose the length of the needles for the height of the floor. For mixtures of gypsum or cement, bending drywall will require a roller with a maximum length of needles. For finishing coatings up to 5 millimeters thick, it is recommended to buy rollers with the thinnest needles.

A pen

The roller handle is simple and extendable.The second option can be adjusted in length, it is convenient in operation (tension is removed from hands). Floor treatment is performed in a standing position, so it is better to immediately purchase a roller with a special extension. When buying a product, pay attention to the length of the handle that is convenient for you, so that you do not have to work, bending over, otherwise your back will quickly tire. Short rollers with a niche to install the holder will have to modify and insert the handle. It is better not to choose this option.

When purchasing, it is better to check with the seller whether the handle is bent, resistant to solvents.

Another advantage is the availability of coverage.protecting from splashing (special cover). The choice of material depends on the treated area. For a large amount of work it is better to purchase a roller made of steel. Usually the price of the roller depends on the type of material and the width of the product.

Manufacturer

The result of your work directly depends on the quality of the needle roller. Therefore, it is recommended to immediately acquire a quality and certified product. You should consider the products of the most popular manufacturers, which include products of domestic companies: “Comfort”, “Intention”, “Sibertech”, “STAYER”, “ZUBR”. Among foreign factories can be identified "MATRIX", "Janser", "Bauma" from Germany, "Corte" from Poland, the Chinese company "888". Some of these companies manufacture products in China, supply them under their own brand, or assemble in Russia. Before buying, you should carefully study the description of the product, pick up a video of the required width.

Model overview

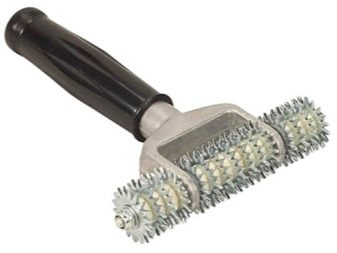

The photo shows a needle tool for drywall. His needles are steel and have the appearance of a cone. The handle is varnished, it is practical for durable use and a variety of manipulations. The width of the roller is 150 mm, which is convenient for applying notches on sheets of drywall. It is suitable for removing the wallpaper.

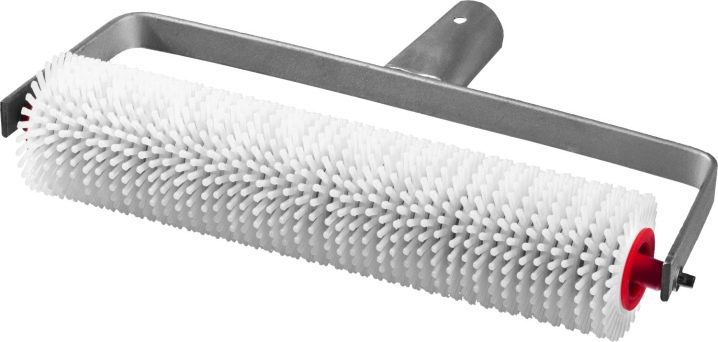

Roller for self-leveling floor with a metal frame and a protective cover. After rolling, pores appear on the floor, but they will smooth out and disappear when completely dry. This option is suitable for rooms with a large area. To align the screed in a small room, it is enough to purchase plastic products with an optimal width of 250 - 300mm.

If necessary, the protective cover can be built independently.

The needle-plated roller is a kind of universal and indispensable tool that contributes to the performance of impeccable work. Do not ignore the need to use it when pouring the floor: as a result, you can get a perfectly level and load-resistant floor.

To learn how to make a roller for self-leveling floor, see the next video.