Wood stoves for giving a long burning

Wood-burning stoves for giving a long burning are used to fill the room with heat without constant regulation of the process of the furnace and with virtually no waste of ash and soot. Therefore, in most of them there is no ash-ash pan, as in the usual heating systems. Installing such a fireplace is the best way to create a cozy homely atmosphere with visible fire with minimal maintenance and with a small amount of firewood.

Long-burning stoves can be selected for the home, for the bath, with simple heating of the room or with additional functions of the hob, with a water or air circuit for heating the adjacent rooms. It is necessary to consider in more detail the most common types of such structures and their features.

Kinds

Prefabricated fireplaces

According to the method of installation of the furnace can be a ready-made versions of factory production and more complex models that need to be built into the interior.If you do not want to carry out complex construction work, then there is the opportunity to buy a factory model, the body of which is made of cast iron and is equipped with transparent doors. Included with such furnaces are often chimneys, which are fixed vertically above the furnace. These devices on the legs are easily transferred, it is possible, if necessary, to install them in a new place.

Embedded

For a small room of 20-30 square meters. The compact model of the built-in fireplace-stove on the wood of long burning is quite suitable. The facade can be lined with bricks or natural stone, and inside there is a factory-made cast-iron firebox with a transparent flap. The advantages of this project are that you can make any design of the fireplace to your liking and organize additional functions: stoves, worktops, heating circuits.

For bath

Features of fireplaces-stoves for baths in their high moisture resistance and compactness for a small room. Sauna models on the wood of long burning are in ready-made versions, which are easily installed in the steam room. Shells are made of high-strength stainless steel, transparent doors of tempered glass.Most designs provide for the adjustment of heat supply, and the dimensions of such products do not exceed 1000 x 800 x 700 mm, which allows them to be easily transported and installed in any corner of the bath.

The most popular and high-quality domestic models of long-burning sauna stoves are “Teplodar”, “Termofor” and “Ermak”, and the imported ones are Finnish “Harvia” and “Kastor”.

With hob

Combining two functions of stoves with a hob are very convenient. They are optimally installed in the kitchen for heating, with which it is convenient to cook dishes on an open fire. An example would be the Okhta model with a solid black steel case, a cast-iron firebox, and a single tempered glass door in a frame. On a ceramic panel with one hotplate in a short time, you can boil a kettle, heat the soup or make dinner. Due to its small size, this stove is suitable even for a small country kitchen, and its appearance with burning firewood is very attractive.

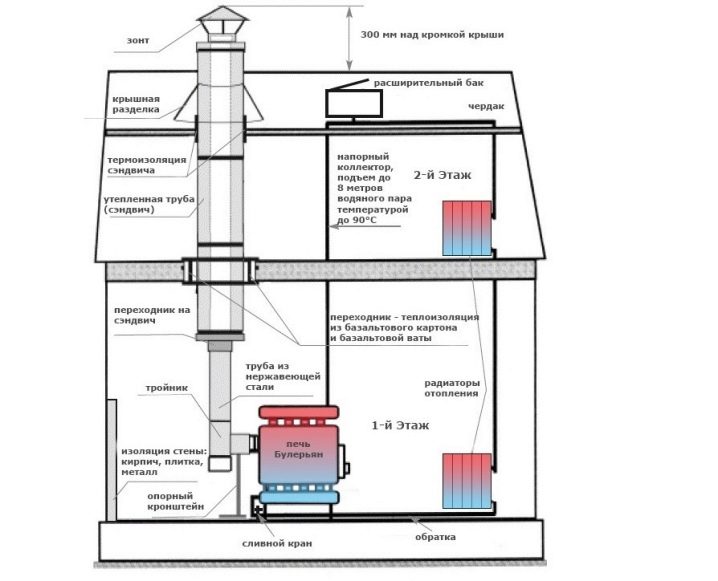

With water or air circuit

Factory models of stoves with water or air circuits allow not only to heat the room in which they are located, but also to provide other rooms in the house with heating and warm water.They can connect a complex pipe system with a length of several tens of meters, through which heated water flows to radiator batteries in adjacent rooms or is displayed on a faucet in the bathroom or bath. The average power of such systems is 9-11 kW, which is quite enough to heat a one-story building with 2-3 rooms, even in severe frosts. Of the most common stoves, fireplaces with a water circuit can be noted "Angara-Aqua" and "Pechora-Aqua."

A fireplace with an air circuit uses hot air for the local heating system in the house. By diluted pipes from the heating device, it penetrates into other rooms. The advantages of this method are more reliable, in contrast to water systems, there is less pressure on the air pipes, and they do not risk breaking suddenly. Among the shortcomings, it is worth noting that the air system is not suitable for rooms with ventilation: a kitchen, a bathroom, a toilet.

Constructions

The design of cast-iron or steel furnaces on the wood of long burning consists of the following elements:

- metal case with legs or heat insulating base to protect the floor;

- firebox;

- transparent heat resistant glass shutter;

- ashpot for collecting soot;

- cast iron grate;

- pipe for the output of combustion products;

- air ducts to ensure a stable burning process.

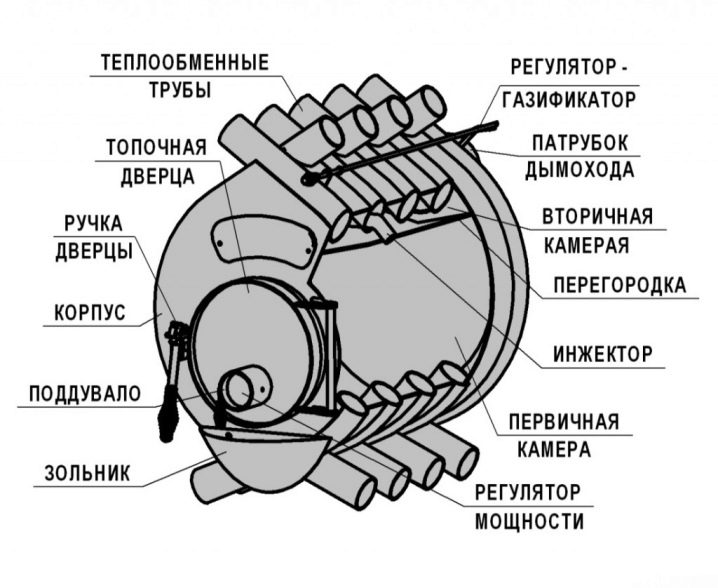

The operation of such a heating device is based on long-term combustion of fuel due to enhanced gas formation processes. That is, in the furnace there is not intense burning, but a slow smoldering of firewood. This releases a large amount of gas. Due to it and the access of additional oxygen through the nozzles, the gaseous products of combustion pass through the stage of secondary afterburning. The result is a minimum of waste, and the efficiency of the stove increases.

Another common design of long-burning stoves is based on the gradual advancement of the flame in stacked wood from top to bottom. Such a process greatly increases the time to complete fuel consumption, and the heat is not less released. As an example, it is worth considering a burning match - if its head is directed upwards, then the flame will move very slowly downwards, if you tilt the head downwards, then the match burns out in a very short time.

The design of a long-burning heating device with a vertical downward movement of the flame is called a Buboufon furnace by the name of its developer. In its firebox is a movable disk, which plays the role of a piston, which descends as the top layer of firewood burns. There is a gap between the disk and the walls of the boiler, through which the formed smoke rises up and out through the chimney. From above, the stove is equipped with an air duct for the intake of oxygen necessary for combustion; the horizontal chimney from the firebox is connected to the chimney that goes outside. In addition, a condensate tank is provided in this design.

Not only wood is used as a fuel, there are varieties of long-burning furnaces on coal and peat briquettes. Their specific heat of combustion is greater, but wood firewood is better suited for creating a cozy atmosphere, pleasant smell of the fire and an aesthetic look in the hearth of such a fireplace.

Stoves-fireplaces with a water circuit consist of almost the same elements as the usual form, which is used to heat a single room. But around the furnace they have a heat exchanger in the form of a radiator or a spiral.It consists of metal pipes through which water circulates. When heated, the liquid enters the heating system, distributed throughout the house.

In addition to buying factory models with a water or air circuit, you can create a project and build fireplaces to your own taste and needs, for example, brick, stone, monolithic. This method is unique in that it is possible to create a fireplace portal with a firebox of any size, and, accordingly, of any power - for large buildings with several floors.

If a ready-made cast-iron or steel fireplace-stove with a heating circuit is purchased, then its technical passport indicates the operating capacity. Based on this value, the model is selected depending on the area of the building:

- 60-200 sq. M. m. - up to 25 kW;

- 200-300 square meters. m. - 25-35 kW;

- 300-600 square meters. m. - 35-60 kW;

- 600-1200 square meters. m. - 60-100 kW.

For a homemade stove, you can calculate the average power produced by yourself, taking into account the type of fuel and its specific heat of combustion, the volume of the firebox, the shape and sectional area of the chimney.

Do it yourself

It is easiest to create an oven-fireplace for long-term combustion for a country house by purchasing a ready-made cast-iron firebox. There are several types of them:

- wall - designed to be mounted in a fireplace near the wall, they will be covered with masonry on three sides, and on the front side there is a transparent valve;

- Corner firebox - installed in the corner type of the fireplace;

- double-sided models have transparent flaps from opposite sides and are suitable for simultaneous heating of two adjacent rooms;

- with a heat exchanger for output to the heating circuit.

After the firebox is purchased, you need to create a project of a fireplace with a facade cladding around it. Here it is necessary to consider whether the metal heating cabinet has a bottom leg or protection against high temperature. If it is not, then you need to build a heat-resistant base of concrete, brick or ceramics in the floor.

Facing the facade of the fireplace with a finished firebox is best done with refractory ceramic or clay bricks in a single layer. After masonry is completed, you should not immediately begin to kindle it. It is necessary that the solution is completely dry and the walls have shrunk. It will take from 2 to 4 weeks. During this time it is worth making a fireplace drying.To do this, it is necessary to heat it daily with a small amount of dry wood, not more than 2 kg.

You can make a wood-burning fireplace with long-burning and homemade firebox, without ordering an expensive cast-iron product in the store. Popular models, which are easily assembled with their own hands, are English fireplaces.

The English fireplace is constructed from classic red brick without additional decorative cladding. The hole of the firebox in his form of a trapeze, and the chimney is straight or slightly tapering from the top of the portal to the ceiling. The flue inside has a curved shape that prevents heat from escaping through the chimney.

Long-term support of heat in the English fireplace is carried out at the expense of the internal walls of the furnace, which are located at a slight angle to the base. Thus, there is a reflection of heat from the walls, the hot air circulates inside. This option is open, that is, it does not have a protective flap made of durable fire-resistant glass.

Independently English fireplace begins to be erected from the foundation. For the construction of the entire height of the floor 2-2.7 m, it is necessary to lay the foundation at least 20-30 cm thick.It can be made from the same brick or pour a strip foundation with formwork. After drying and shrinkage of the foundation, orderly laying of bricks is carried out. A mixture of cement grade M200 with sand is taken as a mortar. At 1 cu. m brickwork will need approximately 0.3 cu. m. of concrete. In the course of the work, you will need a hacksaw or a grinder to cut the brick for the inclined walls inside the hearth of the English fireplace.