Guns for foam bison "foam": the types and principle of operation

Special guns for polyurethane foam of the Zubr trademark allow to save materials and improve the quality of work during construction and repair. Such products are needed by both experienced professionals and beginners, who for the first time are faced with repair and construction work. Let's try to figure out how to choose the right device for applying foam from this brand, what its device is, what are the features, are the rules of work difficult?

Tool importance

Such guns are necessary for each master for a number of reasons. They come in handy in the process of a variety of works:

- during installation and insulation of windows, doors;

- when repairing and warming roofs, attics;

- to ensure absolute and partial sealing;

- during the installation of air conditioning, heating, plumbing;

- to fill empty cavities, seams, joints, cracks;

- when working on insulation and noise insulation;

- when fixing not heavy tiles;

- for the repair of various building structures and many other occupations.

To know exactly which option to choose, you need to get acquainted with this device in more detail.

Device

- Trigger (trigger mechanism).

- Trunk.

- Lever.

- Clamp with dosing adjustment screw.

- The union with the valve.

- Adapter for installing foam.

The main part of the gun - the barrel, which is a regular hollow cylinder. Along its edges there are special valves. The foam bottle is attached to the adapter. Then gently pull the trigger, while definitely need to hold the gun. After that, the assembly material begins to flow through the nozzle, its volume and the feed rate of which can be adjusted with a clamp.

Models

The trademark "Zubr" offers the buyer a variety of models: knowledgeable and non-separable, for use in everyday life and by professionals. Collapsible better because their design provides easy use and repair, allows you to clean the device from the remnants of foam.

Do household models "Buran", "Installer" There is a nozzle from plastic materials.This eliminates the option of cleaning the device in case of freezing foam. The absence of the lock does not allow to adjust the feed rate of the foam, which can increase its consumption, and hence the cost of repairs and construction. The foam in the tank in such models remains not fully used. The obvious advantage of household models is a lower price.

Specialized models for masters "Expert", "Professional", "Drummer", "Buran" made of metal with teflon coating. The barrel is made of steel, which does not rust, there is a sealing ring on the nozzle. The precise and easy operation of the foam dispenser prevents the needle valve from moving, which prevents the gasket from wearing out. The fixture device provides a safe and durable connection to the balloon.

What to consider when choosing?

- Body material. Metal models are better because they will serve you much longer. The easiest way to check the material of the device is a magnet. But metal models have more weight.

- What handled the trunk inside. Teflon-coated models are the best.

- The barrel and nozzle must have a sufficient length that can be measured with a tape measure.

- The integrity of the gearbox (best of cast metal).

- The correctness of the course and unit dispenser.

- No less important is the material from which the needle is made (steel, brass, stainless steel).

- How comfortable is the grip.

- Are there instructions for use, as well as warranty card.

Be very attentive!

- Do not forget to check the integrity of the case, look for defects.

- Require a pistol to be tested.

- Retained cashier's receipt is a guarantee of return of the goods if its quality does not suit you.

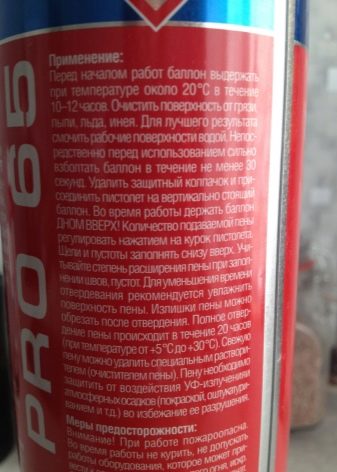

Before using the gun, you need to carry out preparatory activities. If it is necessary to work with assembly foam in winter at low temperatures, it is recommended to heat it to + 5–10 degrees. It is best to use foam for all seasons. The gun itself is immersed in water heated to +20 degrees or kept in a room for at least 10–15 hours.

The place where the foam will be applied should not have a temperature below -5 degrees or be above 30 degrees. Therefore, to perform repair or installation work at temperatures below the data is not recommended.

Safety rules at work are also important. One of the main points is the organization of the airing mode of the room, so the installation material is toxic. Also use special protective masks and gloves. Items specified in the instructions require mandatory implementation.

Order of use

- First make sure that the fixture is assembled correctly and its parts are securely twisted.

- Remove the cap from the cylinder and install it in the gun. Shake the contents by lowering the bottle cap down. The cylinder seat should be lubricated to prevent air from entering. If the gun is not used for some time during operation, it is left in an upright position.

- Click on the trigger. Hissing proof of proper connection of the cylinder. The work can be started only after the foam of the desired consistency begins to come out.

Cavities fill only in certain directions from top to bottom or from left to right. It is necessary to monitor the smoothness, uniformity and continuity of the feed material. It is not recommended to touch the foam until it is completely dry. After hardening, the layer is 2.5–3 cm thick.

Cleaning products and the process itself

In the process of using guns for foam, it is important to clean them in a timely manner. Do not use tap water for cleaning. Because of this, the mechanism may fail and will have to pokapat another gun.

In order to save money and time of the buyer, the Zubr brand offers a line of high-quality tools for cleaning the gun from the remnants of foam. Means for cleaning are issued in cylinders. You can buy them in the company outlets with pistols. Use them in strict accordance with the instructions:

- When cleaning, the bottle with the rinsing solution is inserted into the fixture in the same way as the cylinder with the mounting material.

- For flushing do the necessary number of injections to fill the gun. In this form, it is left for two or three days.

If you can not buy a special tool for cleaning, you can use acetone. In this case, the procedure is the same as when using special cleaning agents.

Related products for repair and installation

In addition to guns for polyurethane foam, the Zubr trademark offers pistols for silicone sealants, which are often used in the maintenance and repair of glass packs.These are multipurpose guns from plastic which can be used for installation and isolation at the same time.

The Bison polyurethane foam is suitable for use at any time of the year, including winter months with negative temperatures. Such products are compatible with any materials used in construction. The exceptions are:

- silicone;

- polyethylene;

- polypropylene;

- teflon.

Frozen yellowish foam. It is light, hard, resilient and porous. Does not contain toxic substances and is absolutely safe in further use. As well as the number of its positive properties include refractoriness, the impossibility of defeating it with various microorganisms (especially fungi). It can be used for sound insulation and thermal insulation of rooms both inside the house and outside. After only 15–20 minutes, its surplus can be cut with a knife without fear of damage.

Benefits

The products of this brand has obvious advantages, among which are the following factors:

- The body of metal does not allow damage, and hence the replacement guns.

- Can be used for a long time.

- Stainless steel and Teflon coating prevent damage to parts and rust.

- The design of the pistol grip makes the device very ergonomic.

- Despite the metal case, these models have less weight.

- The presence of the latch allows you to adjust the material consumption, and therefore significantly saves money.

- The special needle does not pass air that gives stronger connection at installation. In addition, it prevents air from entering the mounting material and it does not increase further in volume.

- The design of the pistols provides a simple operation of all types of models, the ability to assemble, disassemble and clean the device.

- Pistols for different types of materials save time on finding the necessary tools for various types of work.

- Easy operation. If necessary, it is easy to disassemble and reassemble.

- Works with Zubr pistols do not require special qualifications. They can be used by everyone.

- Not very high price with high quality and product reliability.

Quality Reviews

The analysis of consumer feedback on products of the Zubr brand, conducted on sites and forums dedicated to repair and construction, is generally positive.All consumers note the reliability and quality of products, a long service life compared to products of other brands.

Having the opportunity to purchase additional funds of this brand in stores expands the capabilities of the buyer, saves time, effort and finances. Such reviews are the best recommendation of the Zubr brand products.

On how to clean the gun from the dried foam, see in the video below.