Acrylic Adhesive: Types, Benefits and Scope

Acrylic glue is quite popular adhesive and is presented on the market of household chemicals in a large assortment. Due to the huge variety of compositions, glue has found wide application in all areas of construction and repair and installation work.

Specifications

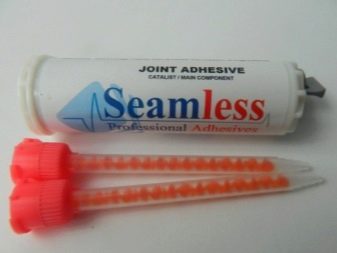

Acrylic adhesive is available in several versions. Each species has its own purpose and has certain operational properties. The material is produced in one- and two-component versions, and the first type is already fully ready for use, and the second one should be diluted with a catalyst, which is water. Of the common features characteristic of all finished compositions, it should be noted liquid consistency and colorless or light yellow shade.

The consumption of acrylic glue varies from 150 to 500 g / m2 and depends on the structure of the material being glued and the purpose of the composition. The ultimate tensile strength is also not the same for all grades and ranges from 5 to 25 kg / cm2. The drying time of the glue ranges from a few minutes for assembly suspensions up to two days for water-dispersion solutions intended for laying parquet. The density of the solutions corresponds to 1-1.25 g / cm3, and the dry residue is 38-45%. The minimum temperature of use is 7 degrees.

Composition

Acrylic adhesive is made in strict accordance with GOST and is a mixture consisting of acrylic resins and various additives. A distinctive feature of these products is the absence of inorganic solvents in their composition, which have a strong odor and are particularly toxic. Instead, organic, consisting of aromatic and chlorinated hydrocarbons are used. Such solvents have a high evaporation rate, are completely non-toxic and harmless to humans and animals. In order for the adhesive composition to be elastic and well applied to the surface, plasticizers are added to the adhesive, which use dibutyl phthalates, dioctyl phthalates and triphenyl phosphate.

The composition of acrylic products include various fillers. They serve to increase the volume, reduce the cost of the material and help reduce the shrinkage of the adhesive during solidification. Fillers are often sand, kaolin and sawdust. The composition of acrylic blends also includes rosin and its esters, frost-resistant additives, defoamer and thickeners.

Release form

The material is produced both in finished and in dry form. Dry formulations are packaged in bags whose weight ranges from 1 to 25 kg. Such mixtures are diluted with water and adjusted to the desired consistency using a construction mixer. The viability of the prepared solution is about half an hour, and therefore it is recommended to dilute as much of the composition as will be used in 30 minutes.

Ready-made adhesives are much more convenient, they do not require preparation and can be used immediately after opening the package. Depending on the purpose and type, the compositions are available in tubes, barrels and cans.

Purpose

Acrylic compositions are widely used for construction and repair and installation work. The material is suitable for combining a huge amount of materials in any combination.Using acrylic blends, you can glue together ceiling and ceramic tiles, mirrors, bath screens, flexible stone, floor coverings, including linoleum and all types of carpeting, as well as glass, drywall and foam. Glue is excellent for working with wood and its derivatives, for example, with MDF, chipboard and laminate.

Due to the absence of highly toxic components, the compositions are widely used for the repair of interior items and household utensils.

Special features

A large number of positive reviews and high consumer demand for acrylic glue due to a number of indisputable advantages of this tool:

- The absolute environmental safety of the glue is due to the absence of toxic components and toxic substances in its composition.

- High fixation strength allows you to glue various materials in any combination. With the help of acrylic glue you can connect glass, wooden, ceramic and metal bases without fear for the result.

- After applying to the working surface, the composition is able to spread evenly. The high permeability of the adhesive makes it possible to connect curved and uneven parts,not paying much attention to their careful preparation.

- High waterproof properties allow using the product as a sealant. Glue tolerates the influence of aggressive environmental factors, so it can be used when conducting outdoor work.

- The wide range, low cost and the presence of fully transparent species greatly facilitate the choice of glue and make it even more popular.

The disadvantages include the possible yellowness, subtlety of the formed seam and the inability to adjust the location of the working elements when using quick-drying species. The disadvantage is an unpleasant odor, which, however, quickly disappears and is completely absent from the dried composition.

Species

Acrylic-based adhesives are classified by purpose, composition and performance.

Cyanacrylate mixtures are single-component, solvent-free and fast-curing compounds. Such solutions are completely non-toxic and are well suited for joining metal, rubber, leather and plastic products and can be used to repair children's toys.The downside of the composition is too fast setting, which does not allow to correct the parts during installation.

Modified mixtures are represented by two-component compositions designed to work with all types of materials without exception.

Glue with the effect of ultraviolet curing is intended for bonding transparent parts of glass and plex. The structure grasps and completely hardens under the influence of ultra-violet radiation.

A feature of acrylic blend with the addition of latex is the absence of a solvent in its composition. Due to this property, the basis of the adhesive is natural and absolutely safe for humans. Latex adhesive is non-flammable and can be used in all conditions of temperature and humidity.

Water-dispersion composition has a two-component design and has high adhesive properties. Hardening occurs after complete evaporation of moisture present in the solution, which allows you to easily adjust the location of the parts to be glued and makes this type of glue most convenient for work.

Acrylic-based tile adhesive is distinguished by excellent fixation of tiles both on the floor and on the wall, it is easy to apply and dries quickly.

Instructions for use

Any bonding should begin with the preparation of the working surface. To do this, both bases must be cleaned of mechanical debris, sand, residues of old paint, primer and dust, and degreased if necessary. If the surfaces are wet or wet, you should wait until they are completely dry, then continue working. When gluing glossy bases to ensure better adhesion of the surface is recommended to clean fine sandpaper.

It is allowed to work with acrylic glue at a temperature from 5 to 35 degrees. After being transported in winter, the glue needs to be adapted slightly to room temperature. To do this, the container with the composition is left in the room for 2-3 hours, after which you can begin work. Some types of glue have a very short period of primary setting, so when gluing parts it is important to correctly calculate the time and quickly correct the parts.

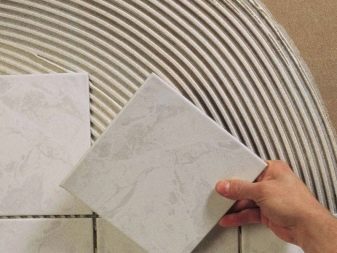

Before using tile adhesive, the surface of the floor or wall should also be prepared. To do this, remove all protruding elements, as well as putty cracks, irregularities and large chips.This can be done with the help of cement-sand mixture or putty. After complete drying of the solution should proceed with the application of a primer mixture. This will provide better adhesion of the acrylic glue to the base and significantly reduce its consumption.

After the surface of the wall or floor is fully prepared, you can begin to glue the tiles. To do this, it is necessary to apply a certain amount of glue to the working surface, after which it is distributed with a notched trowel over the area. It is recommended to hold the tool at an angle of 30 degrees to the base, slightly pressing on it while seeking to fill the voids. When forming the adhesive layer should be closely monitored for its thickness. Too thick a layer can cause the tile to “float” and increase the risk of uneven laying, while too thin will not provide good adhesion and durability of the joint. Excess glue should be immediately removed with a dry cloth, otherwise it will be very difficult to make it after it has hardened.

When using acrylic glue of any modification, the following precautions should be observed:

- Gloves are recommended when working.

- To avoid the appearance of allergic reactions that occur when the adhesive evaporates, installation should be carried out in a well-ventilated area.

- Do not allow the solution to come into contact with the skin and mucous membranes of the nose and eyes. In case of accidental exposure of the product to exposed areas of the body, it is necessary to thoroughly rinse them under running water.

- Keep the glue out of the reach of children.

How to choose?

When choosing a product, consider the place of use and the purpose of the adhesive. For use in everyday life suitable universal composition in the form of a suspension. It has a wide spectrum of action and is characterized by a convenient form of release and ease of application. In addition to the intended purpose, the installation conditions should be taken into account.

When using the composition in conditions of low temperatures, you should choose frost-resistant glue, and when installing in wet rooms - waterproof. The next selection criterion should be the form of release. If gluing of the smooth bases is supposed, the expense will be much less, than during the work with porous surfaces, for example, a carpet or concrete.Therefore, if gluing of soft absorbent or cellular bases is intended, the capacity should be chosen more.

Acrylic glue is deservedly very popular and has many positive reviews. Consumers note high adhesive qualities and low cost of the compositions, durability of the formed joint and transparency of the seam. Attention is paid to the waterproof properties of the adhesive and the possibility of its use as a sealant. Buyers even note some superiority of acrylic compositions over silicone ones and more often choose them. Of the negative properties, it is noted that the glue adheres too quickly, in which it is impossible to correct irregularly positioned parts. In general, there are much more positive reviews, which speaks of the high consumer demand and versatility of acrylic products.

Video review of universal acrylic glue is waiting for you in the video below.