Glue for gas silicate blocks: how to choose and how to use?

When erecting aerated concrete masonry, you should carefully consider the choice of fixing composition. Due to the high porosity of the material, ordinary cement mortar is not suitable here, and special glue is a worthy alternative to it.

Special features

Gas silicate blocks are widespread, especially in private housing. This is due to the affordability of the material, the high rate of cocking of the masonry due to the increased dimensions of the blocks, as well as the relatively low weight, which makes it possible to refuse to prepare deep and solid foundations.

However, this material itself is porous, which reduces the thermal efficiency of the structure. A lot of small holes leave the house warm. In fact, they are "mystics of the cold." These features should be considered when choosing masonry mix for gas silicate blocks.

More and more users are abandoning traditional sand-cement mortar, as special dry adhesive mixtures are available for these materials today. They provide high adhesion of gas silicate blocks, are not absorbed by them and reduce their thermal conductivity.

Despite the higher cost of such glue compared to traditional solutions, ultimately it is more profitable to buy glue, because due to the high absorbency of the cement slurry unit, it will take 6-7 times more. In addition, it is necessary to choose the optimal recipe, purchase and deliver the components of the solution, knead it.

The formulation of the finished glue is carefully checked and tested by the manufacturer. The composition is a cement and fine-grained filler, as well as plasticizers, providing one or other technical characteristics of the adhesive.

Due to the plasticity of the adhesive, it is possible to lay it in a thin (2–5 mm) layer without fear that the seams will lose strength due to the high hygroscopicity of the blocks. Glue demonstrates frost resistance, water resistance. When selecting the appropriate composition can be at any time.

Kinds

Depending on the season of application, there are 2 types of glue:

- Summer. It is similar to autoclaved aerated concrete, based on Portland cement. Due to this, the seams are light, and given their small thickness, you can save on interior decoration. Masking such seams is not necessary.

- Winter. This glue is also called universal, it contains components that make it possible to work with the mixture at low temperatures. At the same time, such glue still has temperature limitations for use - it can be applied only at a temperature not lower than -10 degrees. And the temperature of the glue during operation should be not less than 0. Otherwise, the adhesion of the composition decreases, which affects the solidity of the masonry. It is possible to store and knead the winter mixture only under room conditions, for mixing use water t +60 degrees. The viability of winter glue is noticeably reduced and is on average equal to 30 minutes.

Depending on the form of release, a dry composition for dilution with water and a recently appeared polyurethane composition are isolated. It has a foam consistency and is available in cylinders. Such a composition for gas silicate is ready for use, does not require mixing.

Browse popular brands

It is important to purchase high-quality certified products from famous brands. If you are too cheap goods or nameless packaging, it is better to abandon the purchase. Great risk of running into a fake.

The trust of buyers enjoys the composition of "Zabudova". Glue is not only characterized by increased frost resistance, but also contains special components that make it possible to lay it in winter. Buyers note the ease of application and the affordable cost of the product.

Similar properties have the prestige glue. In addition, it is characterized by high strength and adhesive properties and is suitable not only for laying blocks, but also for cellular boards.

Additional thermal insulation for building blocks can be given using the composition of "Yunis Uniblok". It is suitable for operation in aggressive conditions, primarily in direct contact with water, as well as under the influence of low temperatures. The product contains no toxins, which suggests its absolute environmental safety.

For thin-layer seams, the composition of the Aeroc (manufacturer - Petersburg factory),characterized by increased strength in combination with improved ductility of the adhesive. Due to this, it is possible to lay the glue with a layer from 1 to 3 mm. It is also waterproof and frost-resistant, does not shrink.

Option "EK Chemicals 190"on the contrary, it is laid in a thick layer, so that it can be used with significant (up to 15 mm) height differences. Suitable for year-round use.

The versatility of application (can be used both in summer and in winter) is characterized by glue "Wins 160". User feedback suggests that this is a compound with a good fixing ability. The formed seam remains plastic until the moment of hardening, and then demonstrates moisture resistance and vapor permeability. The advantage is that the glue does not stick to the tools.

Regardless of which of the most reputable brands is preferred, the purchase should take into account:

- Grain size, what determines the thickness of the reservoir. The finer the filler and cement particles, the thinner the adhesive layer will be.

- Adhesion rates. You should look at parameters such as adhesion strength and compressive strength, and choose the composition with the maximum performance.

- Viability, styling and editing composition.Affect the speed of the work - the less experience laying, the longer these values should be.

- Frost resistance. The average is 35-75 cycles, it should be selected taking into account the climatic conditions of the region.

- Layer thickness The optimal composition is that when applied forms a layer with a thickness of 1-3 mm.

How much do you need?

When buying glue for gas silicate blocks, one of the questions arising from a potential buyer concerns what the mixture consumption per 1 m3. First of all it depends on the layer thickness. For thin layers of 1 mm, about 8–9 kg per m3 are sufficient. With an increase in the thickness of the masonry joint up to 3 mm, the required amount of the compound increases to about 25-28 kg / m3.

The geometric accuracy of the blocks also affects material consumption. As is known, glue can not be used with masonry defects of more than 3 mm per 1 m3. But even such a small error leads to an increase in the consumption of the mixture by about 20-30%. Much also depends on the skill of the builders, so the work is best left to professionals. Normally, the calculation is based on the standard 1.5-1.6 kg of glue per 1 m2.

Interestingly, different types of mixtures have almost the same consumption.That is, the amount of the required composition does not depend on whether the “winter” or “summer” version is used, normal or with a high moisture resistance.

Instructions for use

In general, the laying of gas silicate blocks on a special glue is not much different from a similar process of laying brick from a cement-sand mortar. However, certain subtleties still exist here.

Regardless of the composition selected, a solution should be prepared. It is important to take the composition and the liquid in the proportions indicated by the manufacturer.

For mixing the solution is better to use a plastic bucket or a similar container. It is better to add dry ingredients to the water, so better dissolution can be achieved.

The composition is thoroughly kneaded with a mixer until a uniform consistency, and then left for 5-7 minutes. This time is necessary for swelling and better mixing of the particles. Work as a mixer should be at medium speeds, whipping glue is unacceptable. After the indicated time, the solution is stirred once more, after which it is ready for application.

The finished mixture should be checked by applying a notched trowel onto the surface of the block. If it is applied evenly, and grooves remain from the spatula that do not spread, the consistency of the glue is considered suitable.

Glue should be prepared in portions, taking into account its viability in the diluted state. Not lost vitality, but the thickened composition is allowed to mix again with a mixer. It is not allowed to add water or solvents.

Preliminary preparation is also needed for the blocks. They should be carefully examined to ensure the accuracy of the geometric dimensions, the strength of the faces. It is necessary to postpone uneven products with chips and cracks. They will not only reduce the strength of the masonry, but also cause increased consumption of the composition.

The surface of the material must be clean and dry, otherwise the adhesion of the adhesive is reduced. If we are talking about material with smooth surfaces, it is recommended to sand it a little.

Styling tools

For the work required capacity for the dilution of the solution and construction mixer. It is used to knead the solution and give it a uniform consistency. It will not be possible to do this manually due to the high density of the composition.Instead of a mixer, you can use a drill, equipping it with a special nozzle.

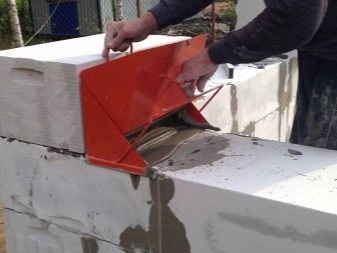

You will also need a smooth trowel, which is convenient to impose glue on the surface of the block. And for leveling the composition is better to use a notched trowel. In addition, for applying a uniform layer of glue of the required thickness, you can use a more advanced tool - a carriage for aerated concrete (or trowel-ladle).

During installation, you also need a rubber hammer, which is convenient to knock blocks after they are laid. This will avoid voids that reduce the strength and reliability of adhesion.

How to put?

The very first row is placed on the cement mortar over the foundation. It allows to level roughnesses, providing durability of a laying. Subsequent rows of blocks are fixed with glue.

The mixture should be placed on the bottom row, as well as the side of each block of the next row. The optimum thickness of the seam should not exceed 3-4 mm. Too thick a seam (if a kind of glue does not provide for this) will dry for a long time and entail an irrational increase in the consumption of the mixture.

The block with the applied glue is laid on the bottom row, if necessary, correct its location, level it (this can be done within 10 minutes after fixation). Each unit should be lightly tapped with a rubber hammer.

At what temperature can you work?

The choice of operating temperature depends on the composition used. For “summer” this indicator is not lower than +5, for “winter” it is not lower than -10 degrees.

Laying aerated concrete during rain, snow is undesirable because it adversely affects adhesion performance. With excessive dry and hot weather there is a risk of shrinkage cracks.

Temperature and moisture levels affect the rate of glue setting. At positive temperatures, the glue hardening takes no more than 1-2 days, and the final setting is the third. With a decrease in temperature, this process becomes longer. However, it is impossible to raise the temperature excessively to accelerate the process of setting, since this is fraught with the appearance of shrinkage cracks.

When the air humidity increases, the drying process of the glue slows down. With excessive air dryness, freezing will occur fasterhowever, microcracks may occur on the surface of the blocks, which adversely affects the solidity of the masonry.

Useful tips from the pros

The reliability and durability of aerated concrete masonry is largely determined by the quality of glue. Many large companies and construction stores offer the purchase of a pilot batch of this composition at a reduced price. You should not refuse such an offer, as this is an opportunity to determine the quality of the glue.

To do this, you can conduct the following tests:

- It is necessary to glue together 2 blocks of aerated concrete with different adhesive compositions. A day should be broken connection. It is optimal if the blocks themselves are deformed and damaged, but not the suture joint. Otherwise (when the place of the fault falls on the seam at least partially), the purchase should be abandoned.

- Shut up several types of mixture and pour it into the same container. A day to weigh each of them. The one with the least weight should be preferred. Low weight indicates that most of the water has evaporated from the solution, which has led to a decrease in thermal conductivity.

In the video below you will see how to properly knead the glue for masonry block.