Knauf Perlfix Adhesive: Features and Specifications

The range of Knauf company is filled with a huge amount of materials, without which it can not do in the construction work. The adhesive mixture Knauf Perlfix in terms of demand among consumers occupies one of the leading places.

Features and benefits

Knauf Perlfix construction adhesive is a gypsum-based powder mix with additives of polymeric substances, due to which the function of coupling with various types of surfaces is increased. Mainly used for facing works. Without problems, she will put sheets of drywall, foam plastic or mineral wool. Warranty from the manufacturer - a few decades.

Knauf Perlfix should be used indoors with standard humidity.It can be slightly elevated, but it is forbidden to apply this glue in places where water can get into.From this it also follows that in the process of work it is not necessary to treat the working surface with water, otherwise the glue will not stick or will soon become unusable.

One of the advantages of Knauf Perlfix glue is the convenience of mixing the dry mix. The finished solution should not turn out to be liquid, the perfect consistency resembles a pasty mass.

Composition

Despite the high marks for the quality of the product, the composition of the Knauf Perlfix glue is quite simple. Initially - this is a natural gypsum. The color of the mixture may be different, for example, pink. This suggests the presence in the composition of the polymers, but also exclusively of natural origin.

Glue Knauf Perlfix has a certificate of conformity, as well as other documents confirming its high quality. Due to the main rule of the manufacturer (minimum cost - maximum quality), all Knauf products without exception receive only positive feedback from satisfied consumers.

Kinds

Each type of material produced by the Knauf trademark is intended for individual repairs. Knauf Perlfix is ideally combined with GWP, but mainly intended for GVL and GCR. In addition, Knauf Perlfix glue is used in the installation of tongue-and-groove slabs (blocks).

As for the technical characteristics of the dry mixture, the composition has the following features:

- increased adhesion strength due to special polymers included in the composition;

- temperature range of use - no more than +30 and not less than +5 degrees;

- setting time - 30 minutes;

- moisture resistance;

- possibility of use in unheated rooms;

- it can be applied in small works, for example, putty;

- strength to mechanical loads.

It should be noted that the most comfortable temperature for the glue Knauf Perlfix is 22-25 degrees, otherwise it will flake off and the work will have to be redone.

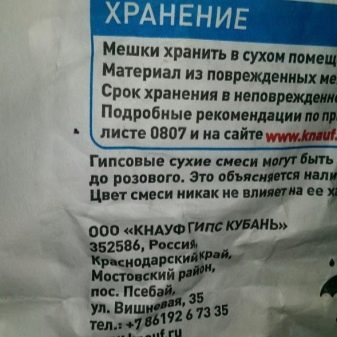

Release form

Knauf Perlfix glue is packaged and sold for sale in special paper bags weighing 30 kg with several levels of protection. The shelf life of the dry mixture is six months.

Another issue that often arises when buying dry mixes in large packages is weight. For the sake of the desire to save money and get more profit, some manufacturers carry out underweight frauds. Knauf in this regard is categorical. Each package is packaged in accordance with the requirements of GOST R 8.579-2001.

How to calculate?

When carrying out installation works an important factor is the correct calculation of the amount of material spent. According to the standards, the calculation is made on 1 m2 of working area. Each manufacturer notes on the packaging data on consumption. On 1 m2 of working surface is spent 5 kg of dry mixture of glue Knauf Perlfix.

How to use?

The instructions for use, which are indicated on the original packaging, say that it is necessary to dilute Knauf Perlfix glue according to the formula 2: 1, that is, 30 liters of dry mixture will require 15 liters of water. It is necessary to dilute the solution in a large container, preferably plastic. At first water pours out, and then glue gradually pours out. At the same time it is necessary to immediately mix the mixture with a construction mixer.

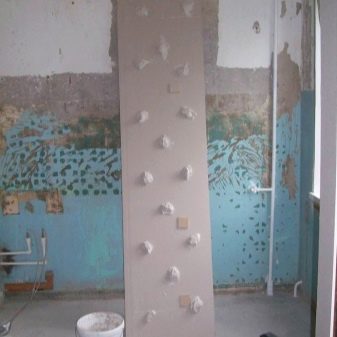

At the end of the work it is necessary to check the resulting solution for the presence of lumps: if they are, then it is necessary to beat up until a homogeneous mass is obtained. The finished glue mass can be used. The working field must also be ready to apply the adhesive composition. The walls must be cleaned of old plaster and dirt. Be sure to primed.

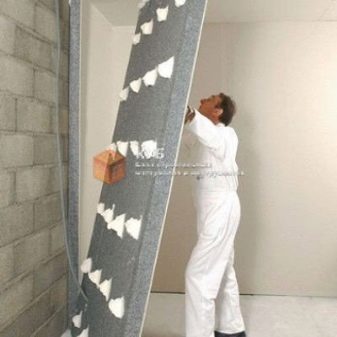

Next, distribute the mortar on the wall with a rubber spatula at intervals of 3-4 cm. Lay the Knauf Perlfix with dots in a checkerboard pattern on the cladding material.Layer thickness for better hitch should be 2 cm. Glue the sheet to the wall.

Installation is quick and very convenient. The time for facing correction is no more than 10 minutes.

Consumer opinion

Judging by the large number of reviews, the glue Knauf Perlfix occupies a high position among the analogues in the world market of building materials.

Users have the following advantages of using a dry Perlfix blend.

- There are no difficulties in work.

- At installation works it is not necessary to provide additional fastenings of facing. Glue holds sheets firmly and securely.

- The composition is universal, it can be used not only as an adhesive, but also as a putty. For example, after installing drywall to close up the seams between the sheets.

- Perlfix Adhesive has an optimal value that is available to any consumer.

Despite the ideal quality, the ecological composition and its versatility, Perlfix dry mix has one unpleasant negative. The term of complete drying of the applied solution is 7 days. It is advisable not to expose the veneered surface to any impact during this time.

Professional Tips

For the first time engaged in repair work, every novice builder faces many problems and issues. And from the first time it is not always possible to do the work efficiently.

That is why it is recommended to listen to the opinions of professionals.

- Before you start, you need to primed the wall. The choice of primer occurs depending on the material of the base. After that, it is necessary to wait for complete drying, while ensuring that particles of dust and fine dirt do not fall on the treated wall.

- So that the ready-to-work glue does not dry quickly, it should be diluted with cold water. Capacity for breeding must be clean.

- For the most durable fixation, the solution should be applied point from the center and further along the perimeter of the sheet.

- At installation of tongue-and-groove plates it is not necessary to use glue solution which is too thick. It is more convenient to make a slightly watery consistency. After fixing the slab, the excess adhesive mass at the joints will be minimal.

- As for the surplus glue: in no case should the waste material be thrown back into the bulk.Because of this error, the working solution begins to dry quickly and hardens twice as fast.

- In the process, the finished adhesive mass in the tank will begin to dry out. In no case can not add water to it, since the original properties of the composition will be lost, and the glue function will disappear.

- It is impossible to calculate exactly how much the mixture will be spent. And it depends on the style of installation. Each individual process requires a certain amount of material. In addition to the traditional version of the application of the composition, there is an alternative method. It is necessary to apply glue to drywall with a notched trowel, but not in the manner required by the standard technology, namely over the entire sheet with a layer thickness of 1 cm. This method provides more opportunities for alignment. If there are irregularities on the wall, then as the sheet is pressed down, the mixture is distributed evenly and goes to the nearest hollow.

- Storing the remaining dry weight of Knauf Perlfix glue does not cause any special problems. An open bag must be sealed as much as possible and placed on a wooden pallet. The storage room for glue should not be wet.

How to glue drywall on glue Knauf Perlfix, see in the next video.