TekhnoNIKOL glue-foam for expanded polystyrene: features of the choice and application

To perform a high-quality repair, professional builders recommend to perform work on the installation of heat-insulating plates on the inner and outer walls, basement, roof and ceiling of the building. On the shelves of hardware stores you can find a huge range of foam for foam polystyrene panels.

The most popular among buyers is the product brand "TechnoNIKOL". The products of this brand is a high-quality product and meets European standards and requirements.

Special features

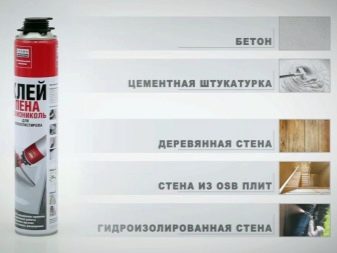

TekhnoNIKOL glue-foam is a fixing compound consisting of polyurethane used for fixing foam sheets and panels made in the extrusion process and used for insulation.High rates of adhesion make it possible to apply it on brick, stone and wooden surfaces, fix plates made of gypsum, gypsum fiber board, cellular concrete. Adding special solutions to the foam increases its resistance to fire.

Modern and convenient packaging (metal container with a volume of 0.4, 0.520, 0.750 and 1 l) makes it possible to significantly reduce the time of work.

Advantages:

- resistance to the appearance of dangerous organic organisms and fungi;

- lack of condensing fluid;

- profitability;

- low thermal conductivity;

- resistance to sudden changes in temperature and the negative influence of precipitation;

- water resistance;

- minimum percentage of expansion;

- short setting period;

- high level of adhesion;

- environmental Safety;

- the absence of freon;

- affordable price range;

- high technical performance;

- ease of use;

- availability in all hardware stores;

- long period of operation;

- wide scope.

Disadvantages:

- the inability to use for fixing mineral wool;

- the need for a special mounting gun.

This type of adhesive is used on objects of different types and purposes:

- civil;

- social;

- industrial;

- defense.

Specifications

The foam of this brand has a number of individual technical characteristics:

- solution consumption from the container capacity - at least 90 percent;

- setting time - 20 minutes;

- full cure time - 1 day;

- moisture level for fixing - no more than 55 percent;

- the density of the solution after solidification is 30 g per cm3;

- adhesion to concrete surface - 0.5 MPa;

- thermal conductivity - 0.04 W / mK;

- temperature range for installation work - from 0 degrees to +40 degrees;

- storage temperature - from + 5 degrees to + 40 degrees;

- Consumption 1 cylinder - 10 square meters.

For safe storage and transportation of foam cylinders must be located strictly in an upright position. Shelf life is from 12 to 18 months.

Types and description

On the shelves of hardware stores you can buy several types of polyurethane foam of the TehnoNIKOL trademark:

- 500 Professional;

- 70 Professional;

- synthetic polymer adhesive for polystyrene foam plates.

Glue-foam 500 Professional - modern universal fixing solution for the installation of insulating sheets of expanded polystyrene. Scope - thermal insulation of walls, floor, roof, foundation and basement. This adhesive can fix aerated concrete (aerated concrete blocks), sheets of plastic, drywall, iron and wood.

Technical features:

- adhesion period - 16 minutes;

- curing time - 1 day;

- color range - light blue;

- high fire level;

- temperature conditions for mounting are from 0 degrees to +40 degrees.

Polyurethane foam 70 Professional - fixing composition consisting of one component in an aerosol package, having an improved formula for increasing the volume of foam output.

Advantages:

- high percentage of primary expansion;

- large volume of output of the composition;

- fire resistant;

- high grip performance.

A wide range of applications makes it possible to use the composition not only for fixing polyurethane plates, but also for insulating windows and doors, fixing sheets of metal and tile, and performing household tasks.

The TehnoNIKOL trademark produces two types of these products:

- all season;

- winter

Technical parameters of the all-season foam:

- density - 30 kg per 1 m3;

- clutch period - 11 minutes;

- curing time - 1 day;

- temperature conditions during the work - from -10 degrees to +35 degrees.

Features of winter foam:

- density - 30 kg per 1 m3;

- the beginning of hardening - 10 minutes;

- full clutch period - 24 hours;

- temperature conditions during the work - from -18 degrees to +35 degrees.

Polyurethane glue is a special type of solution for fixing sheets of expanded polystyrene, XPS plates, ceramic tiles, foam plastic. The base component is polyurethane, which emits isobutane after reaction with air.

Specifications:

- setting time - 20 minutes;

- color - gray.

Before applying the foam, it is necessary to apply a cleaner that degreases the surface.

How to choose?

For quality work, it is necessary to choose the right type of material, taking into account the temperature range of use. The most popular glue foam with a high percentage of resistance to low temperatures. When buying a mixture, you must check the quality certificates from the seller.

There are several rules to consider when choosing an adhesive:

- consistency check - in large specialized stores there are testing devices that determine the structure of the mixture;

- consumption level per 1 m2 should be 130 ml;

- checking the degree of resistance to low temperatures;

- the absence of freon and carbon dioxide in the glue;

- setting period should not be more than 20 minutes.

Reviews and recommendations of experienced craftsmen will help you make the right choice.

Instructions for use

For high-quality performance of work and decrease in level of an expense of foam Experts advise to follow a few rules:

- install the cylinder on an even working base vertically;

- remove the safety cap from the valve and connect the cylinder with the seat of the tool;

- shake the spray can with foam;

- during all stages of work the cylinder must not be positioned horizontally;

- when applying the composition, it is necessary to observe the same distance between the working surface and the gun;

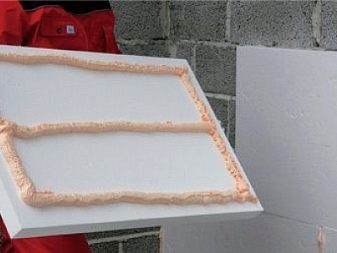

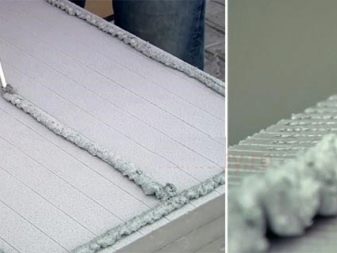

- the width of the bands of the solution should not be more than 30 mm;

- for reliable fixation of heat-insulating materials it is necessary to withstand the expansion of the foam

- 5 minutes after applying the composition to the working surface, it is necessary to attach the panel and hold it until it is fully fixed;

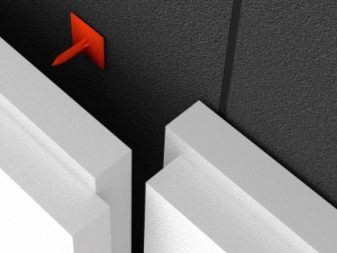

- there should be no gaps and cracks between the fixed plates;

- adjustment of the panels is possible to implement within 10 minutes;

- after complete drying it is necessary to remove the foam and polish the working surface.

Useful tips from the pros

Tips from professional builders:

- transportation of the composition to carry out only in a vertical position;

- Store the tool is recommended in dry rooms;

- temperature conditions for storage - from +5 degrees to + 40 degrees;

- do not heat cylinders above + 50 degrees;

- store in rooms protected from direct sunlight;

- Storage at a temperature of -20 degrees - no more than 7 days.

Before starting work it is necessary to clean the work surface from all types of contamination., scavenge and remnants of old material. To increase the adhesion strength of the panels with the working surface, it is necessary to use expansion dowels. Installation of dowels can be carried out 3 hours after applying the adhesive.

In the event of large gaps between the plates, the empty space must be filled with mounting foam or foam residues. There must be no air flow between the thermal insulation panels and the work surface.

TechnoNIKOL glue-foam - an innovative adhesive composition, allowing to increase the level of fixation of insulation panels and reduce the period of work. Before buying an adhesive, it is necessary to carefully study its properties and specifications; in large specialized stores, consultants will help you make the right choice and purchase the necessary type of product.

In the next video you will find fixation of insulation using adhesive foam "TekhnoNIKOL" for expanded polystyrene.