Liquid nails: what is it and which is better to choose?

Liquid nails appeared relatively recently. Initially, a concrete glue of American manufacture was called. However, due to its high technical and operational characteristics of the composition quickly became widespread, and its name became a household name.

Definition

Liquid nails are a universal mounting adhesive for various, including multi-textured, surfaces (ceramic, glass, metal, plasterboard). In addition to high adhesion, such compositions demonstrate the strength and high speed setting. Just a few seconds is required for the glue to harden.However, its consumption is very economical - one drop is able to glue the surface with a load of up to 50 kg.

The popularity of liquid nails is also due to the ability to tightly connect the surface without using the usual fasteners (nails, screws), which significantly simplifies and reduces the time of repair and construction works. The use of liquid nails eliminates noise and dust, they are not subject to corrosion, unlike standard metal fasteners.

The use of the composition does not require professional skills and time-consuming surface preparation. Another "plus" is the possibility of gluing curved surfaces, including with their incomplete fit.

Such glue is not afraid of exposure to water and low temperatures (with the exception of water-based compounds), fire resistant. Most quality compounds are non-toxic, have a faint neutral smell.

The tool has a convenient form of release - these are tubes of various sizes, the minimum is 0.3 l. As a rule, for their use a special pistol is needed, where the tube is inserted. It is rather simple to use structure even to the nonprofessional.

Composition

The basis of liquid nails is rubber, combined with polymers. The filler is a special grade of clay, characterized by improved ductility. In some formulations, chalk is used instead of clay. The latter not only becomes a filler, but also provides the necessary shade of glue. In the classical formulation (using clay filler), titanium oxide is responsible for the color.

A more outdated formulation also includes acetone. (added to speed up the drying process) and toluon (allows for improved adhesion). However, these components are toxic and most of the advanced manufacturers have refused to add them to the composition of liquid nails.

GOST does not prohibit their use in the compositions, but more and more reputable European and domestic manufacturers do not make them into the composition of liquid nails.

Allocate rubber (neoprene) and acrylic (water-emulsion compositions). The first, as already mentioned, are based on a rubber solvent, the second - an acrylate base. Acrylic copolymers in water-soluble formulations can replace PVC or polyurethane.

Types and specifications

Depending on the base, liquid nails are divided into the following compositions:

Water based

Such compositions have an acrylic base, and therefore are considered completely eco-friendly. They are suitable for bonding surfaces with which a person is in direct contact (interior decoration of living rooms in the first place). When applied and dried, water emulsion liquid nails do not emit an unpleasant smell. The strength characteristics of the composition are lower than those of synthetic analogues, so they are not suitable for gluing heavy surfaces. Among the shortcomings - low moisture resistance and frost resistance, and therefore they are not suitable for use in conditions of high humidity, for outdoor use.

Synthetic origin

Such nails are also called neoprene, and synthetic rubbers are used as a solvent. The adhesive is characterized by high strength, therefore it is suitable for fixing even heavy materials (metals). It is frost resistant, tolerates temperature fluctuations, the effects of moisture. The disadvantage is a slight toxicity.When applied, the adhesive emits an unsharp peculiar odor, which self-volatilizes in 2-3 days after application.

Undoubtedly, the composition of liquid nails determines the scope of their application.

In this regard, the adhesive is divided into 2 types:

- universal;

- special.

Universal glue is widely used because it provides reliable fixation of different surfaces in any conditions. However, in specific conditions, a special modification works better. It can be designed specifically for exterior or interior, dry or wet areas, exclusively for metal surfaces, for expanded polystyrene. Special also include compounds with high rates of adhesion, strength or accelerated setting time of the adhesive.

Specific include heat-resistant glue (used to repair stoves and fireplaces). Waterproof and frost-resistant analogues are usually used for outdoor work. Such compositions are weather-resistant, do not change their characteristics even after several cycles of freezing / defrosting.

Colors

The advantage of liquid nails is also several color variations, so the bonding places are almost invisible.Transparent and translucent compositions are very popular, but not always they can be used due to insufficient adhesion.

In the tube you can find white or beige glue, usually designed for bonding plastic and polystyrene foam elements. The brown shade of liquid nails is usually characteristic of wood-based compounds. The color of the glue coincides with the shade of lacquered wood, which allows you to mask the joints.

For colored materials suitable yellow liquid nails. If this tool is of a suitable composition, but siding and wall panels are attached to it.

If you are not able to pick up the desired shade of liquid nails, you can simply glue the completely dried glue seam into a suitable shade. At the same time, it is necessary to remember about the compatibility of paints and varnishes on different layers. So, water-based glue is better to paint with acrylic paints, rubber seam - with similar synthetic means.

Purpose

Liquid nails are commonly used for bonding metal, wood and chipboard surfaces, glass and mirrors, as well as drywall constructions. It is possible to connect both homogeneous and heterogeneous, as well as loose fitting bases.

The important point is that the glue is not intended for gluing wet surfaces, in which case it loses its ability to adhere to the material. Under wet means not only the surface, which was applied to water or exposed to contact with it, but not enough dried wood.

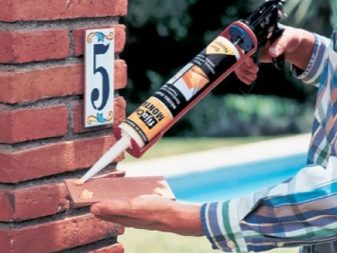

Liquid nails are widely used in repair work. - they can be fixed on heavy wallpaper (for example, bamboo or cork wallpaper, soft wall panels), ceramic tiles. At the same time, the adhesion reliability when using liquid nails will be higher than that shown by traditional masonry compositions.

The only negative is the higher cost of liquid nails, so it is better to use them for facing small surfaces. For laying tile on large areas it is more rational, of course, to use classic masonry mixes. Liquid nails are often used to glue the ceiling panels, they can also fix the baseboard or baguette. For these purposes, it is better to use fast-setting compounds for plastic.

Some manufacturers use liquid nails as a sealant to eliminate cracks on the surface of walls., between walls and floor, in window and doorways. In principle, this is possible, but sealants are elastic, which cannot be said about liquid nails. Theoretically, of course, you can use them as sealing compounds. However, practice shows that it is undesirable to do this. Liquid nails are also suitable for mirrors, but their composition should not contain components that destroy amalgam. As a rule, these are silicone-based compounds.

For bonding metal and concrete bases, only neoprene liquid nails with increased strength are suitable (they must withstand a load of up to 80kg / m2). They are also used for fixing large areas or heavy wooden surfaces, for example, for gluing laminate to a wall. This is one of the technologies for zoning rooms, obtaining the necessary visual effect.

For gluing some flooring materials - linoleum, carpet, you can also use liquid nails. True, it may be too expensive, in addition, you will need a special ultra-strong, vibration-resistant composition.

Liquid nails are often used in combination metal hardware and even used to protect the latter from corrosion.

Manufacturers Overview

You should not expect high quality and safety from nameless compositions of unknown manufacturers. Preference should be given to the original products of a reputable brand, so before buying it is useful to ask the seller for a certificate of conformity.

The leading manufacturer of liquid nails can be called the German company Henkel. Available adhesives Makroflex and "Installation Moment" are universal. There is also a special line for ceiling tiles, cornices and baguettes, separate compositions for particle board, wood, glass, metal. The “Super Strength Plus” modification withstands increased (up to 100 kg / m2) loads.

For gluing heavy structures (wall panels, siding, tiles), the manufacturer recommends choosing the “Moment Installation is extremely durable”. However, it is not suitable for fixing polystyrene bases. In this case, it is better to use “The moment of installation Superstrong” on a water basis.

An extended line of liquid nails can be found at another manufacturer from Germany - Kim Tec. The differentiation of the compositions is made on the basis of the texture of the materials to be glued, indicators of the strength of adhesive bonding. Moisture-resistant formulations are also available.

American glues are famous for their high quality (which is quite logical, because the United States is the birthplace of liquid nails). Among the leaders are the companies Franklin, Macco, whose products are of consistently high quality. The most widely known rubber adhesive is LN601 from Macco, which is characterized by its versatility. However, it is not suitable for use in high humidity conditions.

The “Titan” liquid nails from the Polish manufacturer are practically not inferior to the European compositions. In addition to high quality, the product is characterized by affordability. If you need a composition for ceramic tiles, “Titan WB-50”, “Solvent Free” are suitable, which are characterized by improved adhesion, moisture resistance, and in addition, they withstand small vibrations and dry quickly.

For mirrors, LN-930 or “Zigger 93” is usually recommended. The composition of these liquid nails does not harm the surface, because it does not destroy the amalgam.

Among the compositions that are resistant to elevated levels of humidity, it is worth noting Nail Power, Tub Surround. Their moisture resistance in combination with high strength characteristics allows the use of compositions for tiling bathrooms and kitchens.

The quick-drying formulations include “Solvent Free”, which is convenient to use for gluing ceiling moldings, moldings, baguettes and other elements attached to vertical bases.

Among the universal liquid nails that have received positive feedback from consumers, usually noted "Stayer 41334" (Germany), "Titebond Multi Purpose" (USA), "Universal Installation Moment" (Russia).

For plastic surfaces, the following compounds are recommended: “Quelyd Mastifiks Ultra”, “Kraftool KN-915”. The latter is also suitable for use at elevated levels of humidity.

For tiles, in addition to the compositions of heavy-duty fixation, you can also purchase "Titanium Ceramics and Stone", "Liquid Nails". They are suitable for fixing materials of great mass, including ceramic tiles and artificial stone. Available in white and beige tones, which eliminates the use of grout.

How to choose?

The choice of liquid nails is recommended by the following criteria:

Composition

Depending on the purpose of the composition, you should choose acrylic or rubber liquid nails.The former are optimal for light materials that are operated indoors at normal humidity. In all other cases, it is better to opt for a rubber-based counterpart.

It is preferable to choose the composition with clay filler, since the chalk modifications have the worst adhesion. The composition with chalk should be abandoned even if it is planned to glue metal surfaces. Acetone and taulon are also undesirable in the composition of the glue, the presence of which is usually indicated by a strong pungent odor.

Scope of use

This criterion is largely related to the previous one. For domestic use, usually quite versatile liquid nails. For the bathroom, kitchen and other rooms with high humidity, as well as for external use only moisture-resistant compositions should be selected.

Special glue is also necessary for fixing polystyrene foam. Other types may contain additives that destroy the material.

Setting speed

In most cases, this criterion is not essential when buying liquid nails. However, if we are talking about gluing tiles to the ceiling and similar surfaces, it is better to choose glue with a high setting speed.

If you do not have sufficient skills to work, it is better to choose formulations that have a slower setting speed. This will correct the position of the parts.

Type and weight of glued surfaces

Universal formulations are suitable for solving most construction and repair tasks, but in some cases it is better to use specialized analogues, taking into account the characteristics of the material of the elements. It is important to take into account the weight of products, relating it to the strength of the adhesive. The greater the mass of glued products, the higher should be the ratio of withstand load.

When choosing liquid nails, it is important to pay attention to the compatibility of materials. Thus, water-soluble polyurethane based compounds are not recommended for bonding polyethylene and teflon surfaces. Acrylic compositions are best used on porous bases. When buying, you should pay attention to the shelf life and storage conditions. The first usually does not exceed 12 months if stored at a temperature of -5 ... +30 degrees. Do not allow freezing of the product, its contact with water. When exposed to direct sunlight, the composition is stratified.

Usage guide

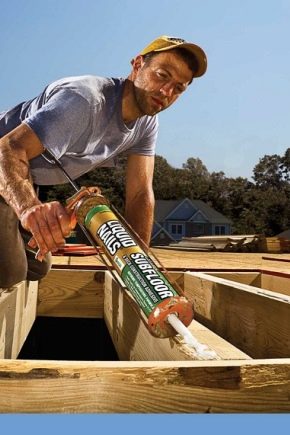

Glue is quite easy to apply at home, without requiring a professional approach. It is fully ready for use, you just need to place the cartridge in a special gun. However, in the absence of such, you can use glue without it. Just be somewhat uncomfortable.

Surfaces must be prepared before applying the adhesive. They must be clean, fat free and dry. Otherwise, the adhesion of the adhesive deteriorates significantly.

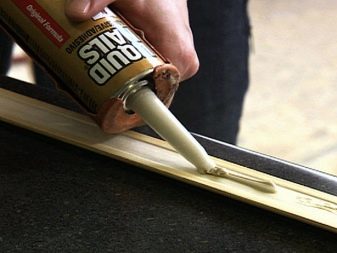

A tube of glue must be installed in a special gun and open. The glue is applied on large surfaces with a snake, for small, light parts a point application is sufficient.

After the glue is applied to the fixed part, it is tightly pressed to the base and held for 1-2 minutes. If necessary, you need to align the horizontal and vertical.

If the parts are heavy enough or suspended, it is recommended to apply a small amount of liquid nails and on the substrate. The final grip will occur in 1-2 days. It is through this time that the glued structure can be operated.

If heavy parts are glued to vertical or inclined surfaces, it is better to ensure their reliable support with wooden or metal supports. Such props should be installed evenly over the entire surface of the fixed part and leave until the glue line is completely dry.

Gluing fragile objects (glass surfaces, mirrors) onto a vertical base also requires the use of props and additional fixation of the element with masking tape to the wall until the glue is completely dry. If heavy surfaces are stuck, fixation can be performed using the following technology. Apply a sufficient amount of glue to the prepared part and apply it to the base for a minute, then remove. Wait 5-7 minutes for the glue to soak into the upper layers of both the part and the working base, then reapply the part to the work surface, level and hold for 2-4 minutes until adhesion. If necessary, install wooden supports to dry the glue.

When working with rubber adhesives, it is recommended to wear a respirator, and protect your skin with gloves. Since the composition is toxic, when used indoors, it is necessary to provide high-quality ventilation of the air. Until hardening, such glue is flammable, so work should be done away from heating and heating devices and sources of fire. If in the process of applying glue hit on the front side or other surfaces that can not be glued, wipe off the drops as soon as possible, first with a dry cloth and then with a damp cloth.

The frozen composition can be removed mechanically, that is, scraping from the surface. However, this may cause damage to the latter. It is better to use mineral solvents or a hair dryer.

When using solvents, it is recommended to carry out a preliminary test on a sample of the material or its inconspicuous part. If 30 minutes after applying the solvent to the sample, it is not damaged, no negative effects are noticed on its surface, you can dissolve the stains on the substrate with this tool. A small amount of solvent should be applied to the glue drops, wait 3-5 minutes and gently remove with a cloth. After that you should wash the coating with clean water.

The easiest and safest method involves heating the solidified glue with a building dryer. After which they will acquire a liquid consistency, the drops are simply removed with a clean rag, and the surface is rinsed with water. If acrylic liquid nails hit the skin, they are washed off with ordinary running water and soap; if rubber, use vegetable oil, petroleum jelly or fat cream.

Useful tips

To work with liquid nails, a gun is needed (visually resembles a syringe) where a cartridge with glue is inserted. One side of the cartridge rests on the wall of the gun, when pressed on a portion of the glue is squeezed out. Due to the simplicity of the design, even a person with no experience in building activities will cope with the application of liquid nails.

For work it is possible to use frame or sheet guns. The first are considered more reliable. Depending on the design, you can choose devices with reverse and without it. The latter are usually used for professional purposes. For domestic use, a pistol without reverse is enough.

If you plan to simultaneously apply several types of liquid nails,it is better to choose professional pistols, in which you can change the tubes, without waiting for the glue to end in the cartridge.

In certain conditions, you can do without a gun. To do this, open the tube and squeeze the glue by pressing on its moving bottom. You can do it with a hammer. However, in this case there is always the risk of uneven release of the adhesive, as well as its splashing.

The top of the tube has a dispenser. Cutting higher or lower, you adjust the thickness of the adhesive layer and, accordingly, its consumption. Manufacturers usually recommend cutting off the tube in the lower division (closer to the cartridge) to obtain an adhesive output of 6 mm.

However, in some cases, a smaller amount of money is sufficient. So, if it is necessary to coat the seams (for example, after a part is fixed or a ceiling plinth, tile), you can cut off a corner of the tube by the first division. Then the glue will come out with a layer with a diameter of 2 mm.

Small and light plastic parts can be glued together by cutting off the tube in the second division. Then a layer 3 mm thick will come out of it. Thicker plastic as well as lightweight wooden parts can be fixed by first cutting off the tube in the third division. The layer produced will be 4 mm.

Thick and heavy parts made of plastic and wood can be "planted" on a 5 mm layer of glue, for the release of which you need to cut off the fourth division of the tube.

In the video below you will find a comparison of hot melt and liquid nails. Is it possible to replace one another? For which surfaces is it better to choose hot melt glue, and for which liquid nails?