Liquid nails "Moment Installation": the types and scope of use

Today, more than ever, liquid nails are widely used in construction and repair works. When performing some types of work they are simply irreplaceable. In some cases, facilitate and accelerate the construction process. There is no need to use perforators, hammers, nails, screws and the like. It is worth considering in more detail what types of liquid nails exist, in what areas they are used.

Purpose

The scope of liquid nails "Moment Installation" is very wide.

HMost of all, they are used in the following cases:

- installation of mirrors on various surfaces;

- gluing protective corners and PVC panels;

- fastening of shelves and decorative elements to any finishing coverings;

- tile installation.

The undeniable advantage of liquid nails "Moment Installation" is water resistance, so they can be safely used in rooms with high humidity: bathrooms, showers, pools, kitchens and others.

The brand "Moment Installation" provides a very large range of adhesive mixtureswhich differ in the field of use. Properly selected glue facilitates the work, guarantees long-term results and safety of materials.

Types and composition

Liquid nails "Moment Installation" composition can be divided into two groups:

- The first category is based on synthetic resins, as well as solvents. A distinctive feature is the high strength and moisture resistance. On the packaging, they are labeled MP.

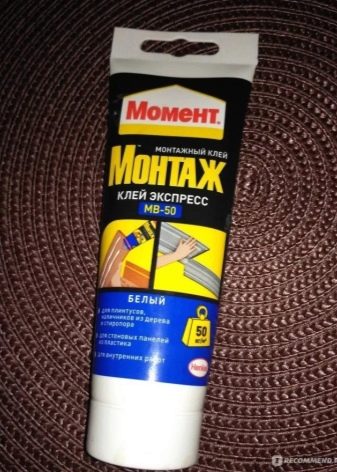

- Adhesive mixtures from the second group are made on the basis of an aqueous dispersion of polyacrylates. They have a neutral chemical composition, more suitable for the installation of plastic materials. Such formulations are labeled in the label MV.

The manufacturer broke the adhesive mixture by category. Their composition meets all the requirements of GOST. On the packages indicate the main characteristics, as well as the types of materials for which this adhesive is intended.

More information on the product can be found in the technical information sheet, which is on the official website of the company "Moment". Therefore, it will not be difficult to find the right "Moment Installation".

To understand all these markings and abbreviations, you should pay attention to some products of the brand "Moment Installation".

- "Express MB-50". This adhesive belongs to the group of acrylates, as evidenced by the reduction in MB. Therefore, it is perfect for working with various raw materials, such as wood, metal, plastic, plaster, ceramics, and so on. It can be used for external and internal work. This glue is used in the installation of decorative products, installation of baseboards and window sills. The only thing that needs to be taken into account in the work is one of the materials being glued, which is well absorbing moisture.

- "Super strong IMP-70". Marking indicates that this adhesive belongs to acrylic, in its composition there are no solvents. It is suitable for working with a large number of materials, including foam and PVC. You should not use this glue in work with polypropylene, polyethylene and teflon. Considering that this glue from the acrylic family, it is necessary that one of the materials being glued absorb moisture. The capital letter "p" in the marking informs about the color of the adhesive mixture - transparent. The number “70” indicates a high initial bonding force of 70 kg / m².Therefore, it is suitable for fastening heavy and large-sized structures.

- "Express Decor MB-45" has white color, belongs to group of acrylic glues. It is used in work with decorative elements from any materials.

- "Universal MP-40" is convenient to use when installing products made of wood, stone, brick, marble, and it also works with glass surfaces. It is quite easily washed off.

- "Extra Strength MR-55" made on the basis of polyvinyl acetate and carbon resins. This is a fairly strong adhesive mixture, which is suitable for fastening and installing heavy structures made of metal, wood, ceramics, plaster. It can be used for installation of PVC, particleboard, MDF panels. The peculiarity of this glue lies in the fact that almost immediately after application it forms a film, which seems dry to the touch. It protects the bonding surface from dust settling. When materials are joined, the film breaks down, providing the best adhesion. It is important that the work items no longer move from their seats, since the strongest grip occurs when the surfaces first come into contact.

Specifications

The main features of liquid nails "Moment Installation" from the family of rubber include the following:

- there are harmful volatile substances in the composition, hence a strong odor; during the work it is recommended to provide good ventilation of the room;

- possesses high moisture resistance and frost resistance (up to -40 ° C);

- is assembly, but can also be used as a sealant;

- works with almost all materials;

- better than acrylates suitable for bonding smooth and moisture-free surfaces;

- some species have an instant grasp;

- storage temperature ranges from -20 to + 30 ° C (after defrosting, completely restores its properties);

- shelf life - 18-24 months;

- it is sold both in cartridges and in tubes weighing 125–400 g;

- working temperature - from -12 to + 35 ° C;

- working time - 10-30 minutes (depending on the type of glue);

- setting occurs after 24 hours; full drying time depends on the outside temperature and air circulation, but not more than 7 days;

- cleaned with white spirit;

- Most of the adhesives are beige.

The technical characteristics of water-based adhesive mixtures are as follows:

- no pungent odor;

- waterproof and frost-resistant (up to -20 ° C);

- suitable for mounting a wide variety of materials;

- the surface must absorb moisture;

- storage temperature - from +5 to + 30 ° C;

- shelf life - 18 months;

- Available in the form of a cartridge and a tube, weighing from 125 to 400 g;

- can be used for indoor and outdoor use;

- working time of glue - from 5 to 15 minutes;

- dyeing is possible after drying (it is recommended to use acrylic paints);

- high initial setting power;

- excess uncured mixture is easily removed with a damp cloth;

- glue color is white, some become transparent after drying.

In the building stores presented a large selection of liquid nails. For more detailed specifications, read the instructions or consult with the seller.

Application

Different types of liquid nails "Moment Installation" has its own characteristics for use. And they also have a different release format. You must carefully read the instructions for use and follow the rules for safe use.

It should adhere to the principles of bonding.

- It is necessary to clear a working surface of foreign elements,degrease if necessary. Bonded materials must be at room temperature. The working air temperature is not lower than + 10 ° C. Some polymer adhesives are specially made to work at sub-zero temperatures.

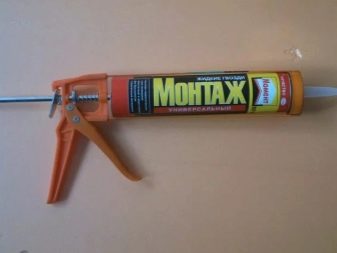

- It is necessary to cut off the protective seal from the cartridge, then put the tip on and at an angle of 45 ° cut off its end to the desired diameter. After install the cartridge in the construction gun. To do this, press the locking tab, pull out the rod, then insert the cartridge into the body of the gun. Hang the rod back to the disk rested in the bottom of the cylinder. After a few clicks on the trigger glue will come out. To stop the flow of glue, you need to press the locking tab, which slightly reduce the pressure in the cartridge.

- It should be applied to one of the surfaces of the adhesive mass. There are several options for how to do this. For example, spot coating is suitable for uneven surfaces. The size of the glue dots is approximately 2x2 cm, the distance between them is 20–30 cm. Another method is a wavy line, which is convenient to use when mounting materials of a large area, since the initial setting is enhanced.Glue is applied to small or narrow elements simply with a straight strip. During the work with some types of glue ("Universal", "For panels") drawing by the roller is possible. This method is convenient when gluing even and smooth materials, especially large sizes. The trowel method is used to create greater contact of the surfaces and almost instantaneous holding capacity. The glue is distributed over the material with a notched trowel (notch depth 0.6 cm), receding 2.5 cm from the edges.

- It is necessary to firmly press and fix the elements for 10-15 minutes. While the glue will dry, you can use masking tape or special fasteners for fixing.

It is worth noting that when gluing materials with a low ability to absorb moisture should adhere to the following nuances.

- do not apply the glue with a continuous coating, because contact with air or the presence of moisture is necessary for the adhesive mixture to dry;

- in some cases, glue is applied, then the parts to be glued are joined, and after 5–10 minutes they are separated to allow the solvent to evaporate; only after that they press the materials tightly against each other.

You can use liquid clusters "Moment Installation" as a sealant, if the seam width is not more than 2 cm. The glue should fill the cavities well, adhering tightly to the side surfaces.

Consumption of liquid nails is on average 200-400 g / m². Do not forget that liquid nails based on synthetic resins are very easily ignited. During the work it is forbidden to smoke and use open fire. Excessive exposure to vapors on the human body leads to sad consequences.

After use, the glue should be kept tightly closed. Empty packaging and residues of glue are disposed of as household waste. It should be avoided in the wastewater. In general, reviews of those who used the Moment Installation liquid nails are positive. Of course, there are those who are not satisfied with the result. But most often this happens because the inappropriate adhesive mixture was originally selected or the application technique was violated. Therefore, it is very important to read everything that is written on the package and follow these tips.

Next, you will learn what liquid nails can be used to install the floorboard on the wall.