Liquid glass for waterproofing

The modern market offers a huge range of waterproofing, differing in terms of use, cost and other characteristics. This product is actively used both in everyday life and during large-scale finishing and construction works. The scope of this composition will be discussed in the article.

General information

Liquid glass is a special solution based on water with the addition of potassium and sodium silicates. The composition has a viscous and at the same time dense structure, due to which the product is ideally suited for waterproofing works.

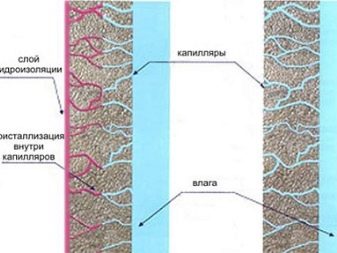

When considering the structure of the material, you can see small crystals.These elements tend to increase after application to the surface. Components fill in small cracks. Thanks to this function, liquid glass has an air-tight and water-repellent property.

How does the product work?

The principle of the special composition has an adhesive ability. Special solution molecules penetrate deep into the porous substance, creating a dense and wear-resistant film. Due to this function, adhesion is formed. According to visual signs, the composition of the glass is similar to rubber, only in the state of liquid. In the manufacture of the product, in addition to the main components, manufacturers use quartz sand and soda.

In the manufacturing process, liquid glass goes through several stages:

- splitting up;

- burning;

- re-crushing, in which the material is converted into powder.

Properties

The building composition has various useful functions.

- Antistatic. Neutralizes the electrification of the surface.

- Antiseptic. Protection of the base against the formation and development of bacteria, fungi and mold.

- Water repellent. Water repellent properties.

- Fire resistance After processing, the material becomes resistant to fire.

- Acid protection. Surface protection from acidic formulations.

- Hardener. Liquid glass coating gives the foundation strength and durability.

Advantages and disadvantages of the composition

Liquid glass, offered by modern trademarks, has many advantages, due to which, the product is kept in the lead in demand. Solution - easy to use "liquid" substance. The product quickly gets into minor defects on the surface, filling them and forming a smooth surface. The composition can be used on surfaces made of various materials (bases made of concrete and wood).

And also worth noting a lot of advantages.

- The material has excellent grip.

- The economical expense allows to carry out work with a minimum of expenses, especially when adding structure to cement mortar. In this case, the product works in the form of penetrating waterproofing.

- Affordable cost has played an important role in the distribution of goods. The price of products is more profitable compared to other waterproofing materials.

- Long service life speaks of practicality and reliability. This indicator is 5 years.To extend the time of use, liquid glass is covered with a layer of enamel, which plays the role of additional protection.

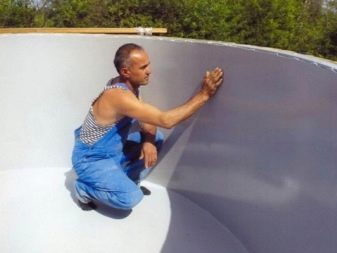

- You can use the product on the basis of premises with high humidity, which is impossible with other insulators (bathroom, swimming pool, basement, etc.).

- Harmless environmentally friendly and safe product, due to which work can be carried out from the inside.

- Given the popularity of products, finding the appropriate composition on the shelves of shops is not difficult.

All the above characteristics have only original products, which have been tested at all stages of production and have been tested before being sent to stores.

Among the shortcomings can be noted some nuances.

- Mortar surfaces should not be treated with a mortar, otherwise destruction is possible.

- Working with the product is not easy. Experts note that the application process is complex, and for its implementation it is necessary to possess certain skills.

- After drawing the structure quickly grabs, forming a film. Therefore, you need to do the work as quickly as possible and at the same time carefully.

- Vystyvshy expendable composition is quite fragile, and therefore it must be combined with other types of waterproofing.

Field of use

To learn more about the capabilities of the product, you need to familiarize yourself with the scope of application.

Modern compositions are used in various cases.

- Excellent waterproofing of artificial ponds, pools and wells.

- When mixing the product with a solution of cement, you get a coating that reliably protects against the damaging effects of groundwater, moisture and moisture.

- Adhesive composition in the construction industry.

- The manufacture of drugs with high refractory and acid-resistant aspects.

- With the help of "liquid" glue, you can protect the structure from fungus, mold and other bacteria. The mixture is covered with prepared areas.

- Repair of products from materials such as wood, cardboard, porcelain and paper.

- The product has proven itself as a product for sealing seams inactive.

- Suitable composition for plastering pools.

- The composition is introduced into the soil in the event that it is planned to build a building on weak soils. This prevents shrinkage.

There are also additional features.

- Professional builders often use a mixture of silicate glue and water glass.The resulting solution is used in laying linoleum and PVC tiles. And also the structure is useful for seal of seams and joints.

- In the production of non-flammable fabric, the solution is applied in the form of impregnation.

- In gardening, this material has also found its application. If there are wounds in the trees, they are treated with a compound. It will protect the plant from bacteria and pests.

There are several uses for waterproofing.

- If you are looking for a coating solution for waterproofing, be sure to pay attention to modern liquid glass. Before starting installation of roll insulation, several layers of mortar are applied to the substrate.

- Cement mixture with a solution suitable for eliminating leaks. The structure will cope even with serious problems.

- To improve the solidity and the increased degree of waterproofing liquid glass is added to concrete.

Product types

Among the assortment of building stores, several species have become particularly popular.

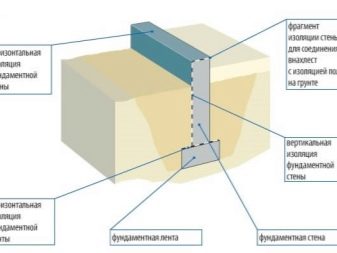

- Potassium composition. This product has excellent stickiness. Most often it is used for waterproofing the foundation.Manufacturing technology includes the impregnation of antiseptic action, which is part. The material perfectly interacts with mineral-based products.

- Sodium glass. Due to the addition of metal, the stability characteristic of the glass is improved. The product is not afraid of acids. The composition does not have a glossy shine, and therefore it is used for dyeing bases.

Tips in work

For proper use of liquid glass, use the advice of professionals.

- Before applying the composition to the surface it must be diluted with water in the following proportions: per 100 grams of powder 200 grams of water. Consumption of the product will be 300 g of the mixture per "square".

- Waterproofing using the above composition is carried out on concrete walls with irregularities, as well as on vertical surfaces with weathered plaster.

- To prepare the composition of liquid glass and concrete, observe the following proportions: 1: 10.

- Be sure to use special protective clothing and other accessories during work.

Step-by-step use of the composition as a waterproofing:

- the floor, foundation or any other surface must be cleaned and dried;

- the product is applied with a brush or roller;

- the second layer of the product is applied after half an hour;

- apply the composition gently and evenly, avoiding the formation of gaps;

- then you need to prepare a protective layer, for the preparation of which sand and cement are used, while adding liquid glass to the mixture, taking into account the 1: 1 ratio;

- the mixture must be thoroughly mixed and applied to the surface as soon as possible, re-application is not necessary;

- stirring constantly, the composition is applied to the substrate using a spatula.

Before using the product, carefully inspect it for the presence of lumps and various impurities. And also pay attention to the shelf life of the composition.

Consider how to use the solution for the treatment of the foundation.

- As in the first case, it is necessary to clean the treated base. It is advisable to sand the surface with sandpaper.

- To apply the compound evenly, use a standard construction roller.

- After 30 minutes, apply the second layer and, if necessary, the third.

Note: for insulation, use mineral wool or regular foam.

Recommendations for selection

The market of building mixtures offers a huge variety of products from foreign and domestic manufacturers. In favor of which products to make a choice is a personal matter of each buyer, however, make sure that you spend money on a certified product. Relevant documents indicate that the product is made with the necessary standards.

Be sure to familiarize yourself with the scope of the product. Information about this should be shown on the packaging. To find the perfect balance between price and quality, rate the wide range, compare prices and make a choice. The average price of liquid glass has about 300 rubles per 10 liters. The cost varies depending on the composition, brand, mark-up store and other aspects.

Reviews

Summing up the article views of real buyers. On thematic sites, product reviews are shared by both ordinary consumers and professionals from the construction and repair industry. Despite the huge variety of compositions of this type, they all have the same characteristics and scope of use.

Most reviews indicate that the purchase of liquid glass for surface treatment - more profitable to purchase. About 80% of reviews are currently positive.Consumers note a favorable price, a variety of methods of application and excellent adhesion.

In negative reviews, users indicate the fragility of the film. To obtain a durable composition, it is necessary to use various additives (concrete, cement).

In the next video you will find the use of liquid glass for waterproofing.