How to make a greenhouse for plants?

A greenhouse is a no less effective analogue of a greenhouse, which is present in many summer and garden plots. Such facilities are very popular among the owners of private houses, as they are easy to use. Moreover, making a high-quality greenhouse with your own hands is not difficult. Today we will analyze in detail how to properly construct these structures and what we need to take into account.

Special features

Nowadays, homemade greenhouse or greenhouse is difficult to surprise anyone. Such facilities can be found at many sites. They are not only made with their own hands, but also purchased in specialized outlets or ordered from experienced craftsmen.Of course, it will be cheaper to make this design yourself. In addition, the owners will have the opportunity to create the structure of the desired shape.

Greenhouses are good because they can have almost any structure. This can be not only simple and uncomplicated buildings, supplemented with a coating in the form of a film, but also more attractive and durable structures with glass or polycarbonate inserts. In appearance, the latter cease to resemble standard greenhouses - they are more like full-fledged greenhouses.

Greenhouses may have different dimensions. Of course, in most cases such buildings are more compact than standard greenhouses, but their efficiency does not suffer from this. Just a small greenhouse will be able to arrange a small number of plants.

Keep in mind that greenhouses are designed for early planting. Most often, in such conditions, vegetables are grown in cold regions, but in the summer season. Heating systems are usually present in greenhouses, and they are far from always in greenhouses. Thanks to these features, we can conclude that the production of a greenhouse is simpler and faster than the construction of a full-fledged greenhouse (if only because of its modest dimensions).

But do not think that in the manufacture of a greenhouse will not have to adhere to a certain construction technology. For example, we must not forget about the selection of a suitable place for such construction. Usually, people first choose a certain territory for a greenhouse and only after that proceed to its construction. Many owners install these buildings near the walls of the barn or house. The result is very comfortable and reliable facilities.

Before proceeding to the construction of a greenhouse, you will also need to make a detailed draft of it. Based on the resulting drawing and scheme, it will be much easier and faster to build a structure of the desired modification. That is why neglect planning greenhouse is not worth it.

You should also note that modern greenhouses are made from a variety of materials. Most owners of summer cottages and country plots choose plastic pipes or wood for the construction of these structures. Sheath the resulting base can be using a special film or polycarbonate - the choice here is only for the owners of the site.

Purpose

A greenhouse is a very useful and practical building, to the construction of which many owners of villas and private houses turn to their own plots.The demand for these structures is due to the fact that they are intended for various purposes. Here are some of them:

- In most cases, greenhouses are used for growing seedlings and planting them further in open ground (here lies the difference from the greenhouse - plants can be there throughout the year);

- well-executed greenhouse with an aesthetic appearance, is able to decorate the land, harmoniously blend into the landscape design.

If you decide to acquire such a building, then you should know that it is absolutely not suitable for the winter season. If you want to keep the seedlings in a warm and comfortable environment throughout the year, then you should build a full-fledged greenhouse. The greenhouse is not designed for such operation. It is used only in warm seasons.

Types of construction

Many users believe that all greenhouses are the same and represent the construction of an elementary modification. In fact, there are several varieties of these structures. They vary in shape and design. Before embarking on the independent production of such a building at home, need to be familiar with all possible options.

- Most often at the sites you can find greenhouses made of wooden boards. Useful volume in such buildings can be closed with a lid in the form of frames with glass. They can be opened and closed, if necessary. Greenhouses of this type are ideal for growing seedlings or a variety of greenery in order to get it to the table as early as possible.

- There is another type of greenhouse - temporary. It is mounted exclusively for the spring-summer season. Make such options from wooden frames, fiberglass reinforcement and popular plastic film. For a long time, such a structure is unlikely to serve at least for the reason that this film is extremely vulnerable and can easily be seriously damaged.

Consider that this type of greenhouse can last for many years if it is disassembled into individual parts for the winter and stored in a separate enclosed area. The old film can be seamlessly replaced with a new one - it will not take a lot of time and effort.

- Some homemade craftsmen make greenhouses from old large-sized barrels These options are also better to contact only in the spring.However, these greenhouses at the time of the winter season can not move from the land. To avoid this process, they are usually converted into open flower beds or beds.

- A more complicated type of greenhouse, the system of which is designed for heating of a forced nature, is often constructed from boards, metal-plastic reinforcement, thick polyethylene film, or polycarbonate popular in such works. These types of greenhouses are good because they can be safely put into action immediately after the snow melts. In addition, it is very convenient to use these buildings, since it will be possible to go inside the greenhouse to take care of the crops.

- A greenhouse of the capital type, equipped with all the necessary devices for the formation of an optimal microclimate, is no less useful and in demand. Such structures are permissible to operate throughout the year. However, they need to be built only on high-quality (if not too deep) foundation bases or on a brick foundation. In addition, the capital greenhouse necessarily need a good warming - then it will be more efficient and useful in the application.

Often, such multifunctional and well-thought-out constructions are attached to certain walls of the outbuildings on the site or to the residential building itself. With this decision to enter into such buildings will be much more convenient, as well as care for the cultures that will be inside. In addition, the seedlings will be comfortable in such conditions at any time of the year. Often, the owners organize the entrance to such greenhouses right from home - this is a very popular and convenient solution.

If you want to significantly save on the heating of the constructed structure in the winter season, then you can turn to the creation of a greenhouse-thermos. For its construction, dig a pit with a depth of not less than 1700-2000 mm. The dug space is covered with a special transparent roof. In this version it is extremely important to take care of high-quality ventilation.

Few people turn to the organization of such a greenhouse, because it takes a lot of free time. By itself, this process is considered quite time-consuming. However, it should be noted that such a structure will provide an opportunity to significantly save on payment for energy resources.

Fabrication materials for the frame

As well as full-fledged greenhouses and greenhouses, greenhouses can be made from a variety of materials. Based on the selected raw materials, we can talk about the operational characteristics of the building and its reliability. Let us consider in more detail which materials are most often chosen for the creation of these structures.

Tree

Constructions with inexpensive wooden frames are rightfully recognized as one of the most common and popular. Most summer residents resort to the manufacture of these very structures. Users are attracted not only by the cheapness of wooden frames, but also by their attractive appearance. Often, these outbuildings adorn the landscape design, especially if you paint them in the color you like. These efficient and environmentally friendly buildings have their drawbacks, for example:

- a wooden greenhouse is unlikely to last for a long time, since the specified material, without proper care, begins to inevitably collapse - it can dry out, crack, deteriorate under the onslaught of harmful insects (these problems can be avoided only with the use of antiseptic agents);

- material for the manufacture of wooden greenhouses should be chosen as carefully and carefully as possible -the home craftsman will have to find the boards without damage, knots, cracks, traces of rotting and uneven surfaces;

- if such an erection turns out to be in conditions of high humidity, then protective impregnations are unlikely to save it from inevitable rotting.

Metal

The most reliable and durable are considered the construction of a metal profile. In most cases, such materials are addressed in the manufacture of capital buildings. These structures, for example, from the profile pipe, it is best to put on a good foundation foundation. They can be made with any shape and structure. Thus, arched metal greenhouses assembled from several separate arcs are considered to be the most popular and attractive. Products of this form today are widely distributed and used in a variety of conditions. They are sheathed with film and polycarbonate.

Often, the metal in them is combined with PVC pipes - as a result, reliable and durable buildings are obtained.

Plastic

Not bad arched structures are also obtained from PVC pipes. These materials tend to be lightweight.They bend without problems, if necessary, but they do not deform or break. You can not only build plastic frames with your own hands, but also buy a ready-made version in a specialized store, which will only be correctly fixed on the site and trimmed with selected materials.

When choosing a finished model, it is very important to pay attention to the marking of the pipes, as well as the parameter of their length. These designations must be suitable, otherwise the design may not be sufficiently reliable.

Finish

Not only greenhouse frames are assembled from various materials. Consumers can choose and suitable material for finishing these buildings. In this case, do not use good old sheets of drywall or wall paneling. Consider the most common options used to design the frame base of the greenhouse.

- Glass. This fragile, but attractive material is most often addressed in the decoration of the foundations of wood. Most often glass inserts are installed in capital structures. They are fixed with frames, from which the very construction is erected.Often, home craftsmen turn to the use of already old window frames in the manufacture of an effective greenhouse. Due to the rather complicated installation and high brittleness, glass parts are not often used. In addition, these high quality items can be quite expensive.

- Special greenhouse film (HDPE). This decoration is simple and reinforced. She can arrange buildings made of frame bases of any type. It can be both wooden, and metal or plastic constructions. It should be noted that film finishing is cheap, and therefore it is found on greenhouses and greenhouses very often. But we must not forget that this material is short-lived and can be easily damaged.

- Cellular polycarbonate. The most popular covering material for greenhouses is cellular polycarbonate. According to experts, such a finish is not very suitable for frame foundations constructed from plastic pipes. It is important to keep in mind that the incompatibility of the two types of material can reduce the service life of the greenhouse for a couple of years. The ideal option in this case would be a base of galvanized or galvanized profile pipe.

- Spunbond. Many gardeners cover self-made greenhouses with materials such as spunbond. It is a non-woven material made from molten polymer. This raw material boasts high air permeability, homogeneous structure, translucency, low weight, high strength, resistance to precipitation and environmental friendliness. Spunbond is much more practical and reliable than the standard greenhouse film, so it is often approached.

Sizes and shapes

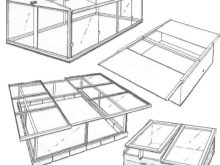

Like greenhouses, greenhouses can be made with different shapes and dimensional parameters. As for the direct structure of the future outbuilding, it will directly depend on the type of frame that you will prepare for the subsequent decoration. Frame grounds for greenhouses may be as follows:

- with vertically directed walls;

- with inclined walls;

- single-pitch;

- in the form of an arch (assembled by an arc);

- gable;

- with roof mansard type.

Greenhouse forms are as follows:

- hemispherical;

- rectangular;

- pyramidal;

- cap-like;

- trapezoidal;

- oval;

- triangular.

The most popular are gable designs. They are not only considered to be easy to use, but also look pretty. Often, high dual-sided greenhouses with glass trim become a real decoration of the site, especially if they grow beautiful and colorful plants, such as flowers.

Slightly less often there are greenhouses made in the form of a pyramid. They can be very small, and quite large and tall. Many users are sure that they can only be decorated with glass. In fact, for this facility you can buy a film or polycarbonate - the choice is only for the owners.

Regardless of what materials you choose to build a greenhouse, you will need to take into account its dimensional parameters. They are always indicated in the plan and drawing of the future erection before proceeding to its direct manufacture. If the greenhouse is too small or too large, it will lead to loss of material. In addition, to use such buildings may not be very convenient. In this case, you need to focus on the area on which the greenhouse structure will be located.It is important to take into account the immediate requirements of the owners - to grow too big a crop for a small family makes no sense - it will be an impractical solution.

Experts always recommend to allocate a place for planting, which are subsequently planned to be planted in open ground. If the greenhouse is built for commercial purposes (for example, for sale), then the size of the future construction will depend on the planned crop turnover. In any case, you should not waste your time only on mini-greenhouses, especially if you have a fairly spacious area. Also an important parameter is the width of the building - any summer resident knows that in a narrow greenhouse it is difficult and not very convenient to care for plantings.

The optimum is the width of the greenhouse in 220-250 cm (this is enough to accommodate 2 beds) or 350 cm (suitable for greenhouses, where there are 3 beds with a couple of passes between them). If, however, taking into account the parameter width of the door, the most modest size will be about 2.4 m. If you plan to use cars or trucks, it is recommended to prepare door openings of 90 cm and more. Designs with two passes, as well as shelving, are most often performed with a width of 370-400 cm.

The height of the greenhouse should be such that the plants could grow freely and nothing constrained them. Usually this option is chosen arbitrarily based on the wishes of the owners of the site.

Choosing a location

As mentioned earlier, greenhouses need to be located in suitable places. And this applies to both street and home options. First consider where the greenhouses should be in the conditions of the site. Mainly this outbuilding should be located in a completely open space. A transparent base should “look” on the south side. Construction and planting in it should be in contact with natural light throughout the day as long as possible. Extra blackout should not be. The length of the future crop and its quality in general will depend on how long the beds feed on sunlight.

If we are talking about a small greenhouse, designed for operation in the conditions of a city apartment, then here one usually chooses a window sill or a glazed balcony / loggia. Often, people assemble entire cabinets with shelves that have small greenhouses or greenhouses.Such facilities can not only be made with your own hands, but also purchased ready-made. In any case, it is very important to ensure open access to natural light for the greenhouse. If that is not enough, then it is necessary to install artificial lighting devices - lamps.

How to do it yourself: step by step instructions

As mentioned above, the greenhouse can be made by hand. And it can be a construction of any material. Consider a few detailed examples for the manufacture of such erections.

From wood

Most summer residents make wood gabled greenhouses. They will grow tomatoes and other similar crops. At one of the end halves of such buildings establish a door leaf, which will be responsible for the person's access to the landings to care for them.

In all cases, the installation of a wooden greenhouse begins with the installation of the carrying barWhich is attached to the base basis (tape or columnar). As a rule, the timber has a thickness slightly larger than other wooden parts that are in the frame of the building. In this case, all components are coated with an antiseptic composition.

All fasteners should be as strong and reliable as possible. For this, it is allowed to use reinforcement or anchor / metal bolts. We must not forget about the integrity of the timber, which plays the role of foundation. It must be intact - without cracks, chips and hints of rotting. If there are such defects on the basis, then the building will not be sufficiently durable.

Wooden "house" must be built in accordance with a pre-drafted project and a drawing of the future construction. If we consider this process easier, then it looks like this: first, 2 side and 2 end walls are assembled, and then they are fastened using self-tapping screws, angles, metal profiles and clamps. When the original box is ready, you can begin to fix the trusses. Their number depends on the wishes of the owners, but it must be borne in mind that the more rafters will be in the construction, the easier it will be to install a covering material. In addition, in such conditions, the whole structure will be more reliable.

Having completed the fixing of all the rafters, you can proceed to the installation of the ridge part of the roof of the greenhouse. It is attached to the upper groove rafters.At the same time, you will need to install wind boards using the slots on the sides of the trusses. At the same time, it is necessary to rely on the preliminary drawing and plan. All parts must necessarily be made from whole raw materials.

The final step will be the installation of the doorway and the vents necessary for airing the greenhouse. Then it remains only to complete the structure with a covering. Further construction will be ready for use.

From plastic pipes

Many gardeners opt for home-made greenhouses made of PVC pipes. Such buildings are often cheap. In addition, they are more durable and wear-resistant than wooden versions. They can be easily disassembled and reassembled if necessary.

If you plan to put a stationary greenhouse of PVC pipes on the site, then it is recommended to build a strip or column foundation for it. If we are talking about a temporary collapsible structure, then here the ideal solution would not be to prepare the foundation at all. It will be enough just to dig in the pins, and then fix the existing ground with the help of boards.

With the use of pins, the base is prepared as follows:

- Reliable metal pins are dug firmly into the soil in a dedicated area;

- they should be no more than 30 cm above the ground;

- after that, you need to put the pipe on the pin with one edge;

- then it is necessary to bend the pipe so that its second edge is also placed on the pin inserted parallel to the first.

After the preparation of such a foundation, you can begin to design the structure itself from PVC pipes.

- When the arcs that perform the functions of the fundamentals are fixed, they will need to be attached to each other. To do this, you can use a pipe with a length corresponding to the entire building.

- The long tube (or 2 short ones, but fastened together) should be in the center. It will need to be securely fixed using ropes or clamps. At this stage, it is possible to consider the assembly of the frame base completed.

- The most successful coating of such a base will become popular today polycarbonate or a special polyethylene film. If you chose the first material, then you need to know that its thickness should not be less than 4 mm. The size parameter of the sheet can be almost anything, because the specified material is seamlessly cropped if necessary.It can easily be adjusted to the dimensions of the greenhouse. If you picked up the film for finishing, then it should be cut into strips and attached to the arches on double-sided tape or special fasteners for pipes.

- Fasteners of polycarbonate or polyethylene film must be overlapped. In order to interconnect the individual sheets, they often use screws with large hats or special thermo washers. In carrying out these works, it is very important to pay enough attention to the quality of the resulting joints. To make them tight, it is permissible to refer to a special tape.

If everything was done correctly, the design will turn out effective and high quality. In no case do not leave gaps and wide joints between individual materials, otherwise there will be very little use from such a greenhouse.

From galvanized steel profile

Greenhouses and greenhouses in many cases are built from galvanized steel profile. From this material it is possible to build a building of any shape and modification. There are also no size limits. For construction work you will need these tools:

- measuring tape;

- building level (it is desirable to use a laser or bubble - they are the most convenient);

- plummet;

- scissors for metal;

- screwdriver.

Installation work in this case must begin with the installation of the guide profile. It is attached to the foundation, using screws. One of the upper beams should serve as a connection for all sections. They, in turn, should be at such a distance, so that the entire structure was as rigid and strong as possible. Usually the step takes the third or fourth part of the sheet of polycarbonate. The galvanized greenhouse under the covering material is made in the same way. It is only important to think out in advance how you will attach the film to the frame base. The rest of the scheme of installation work is the same as in the manufacture of greenhouse from PVC pipes.

Many gardeners turn to greenhouses from galvanized sheet in order to build a high-quality greenhouse for growing tomatoes. It is easy to make it yourself, and the result is very strong and durable buildings that do not require special care. In addition, every summer resident knowsthat tomatoes must grow in certain temperature conditions (the temperature should not be too low), therefore it is recommended to think in advance about heating or heating galvanized structures.

From window frames

In many areas there are interesting greenhouses, made by owners of ordinary window frames. Of course, these facilities are hardly created for the cultivation of tall crops, but as an effective home-made greenhouse it will be quite convenient to use them.

Such construction will not cost the owners expensive. For its manufacture will need only the old window frames. If glasses are already present in them, then it is permissible to leave them in their places and use them as a replacement for the main covering material. If the frames are empty, then after installation they are allowed to be supplemented with a film or polycarbonate sheets must be installed in empty areas.

Consider that for such a greenhouse, even if it is small, it is necessary to make a foundation. For this, it is allowed to install a wooden frame of timber or planks. In this situation, it is better to use a timber of 50x50 mm or a board with a thickness of 40 mm.

The frame of this greenhouse will consist of racks and lower straps. The latter are usually made of boards of the same size. At the same time, elements such as racks should be fixed at the same distance from each other so that the frame can easily stand between them. To build a roof, it is recommended to use a bar, because it boasts good strength characteristics. In addition, with such a detail, the greenhouse will be protected from damage from heavy snow in the winter.

As for fastening frames to the supporting parts - here it is better to use screws and nails. Fix the frame will need both inside and outside. All the cracks that remain during the assembly of the structure, you need to zeni. The roof of this greenhouse, as well as the walls, it is better to finish with polycarbonate sheets or film. In such conditions, planting will receive a sufficient amount of natural sunlight.

Operation Tips

A home-made greenhouse, made according to the rules, will certainly prove to be effective - the plants growing in it will bring a good harvest, especially if you provide them with proper care.However, it is not enough just to competently perform such an erection. It is necessary to take into account a number of recommendations / advice from experts so that the construction does not disappoint you.

- Experts recommend making deep type greenhouses. Such structures will keep in their place firmly and reliably enough - they will not be afraid of strong wind gusts or mechanical external influences.

- Make sure that planting, "living" in the greenhouse, are not subject to the detrimental effect of temperature differences. In such conditions, seedlings can get sick or even die.

- If you want to provide the plants with optimal conditions in the greenhouse, you can turn to automatic systems. For example, it may be the automatic opening of the vents in the building. In this case, can be used both electrical and mechanical devices.

- If you decide to finish a greenhouse built with your own hands with a special film, then you should know that experts recommend turning to similar products whose thickness is at least 150 microns.

- If you are going to grow zucchini in a homemade greenhouse, it can be trimmed with both film and polycarbonate.

- A high-quality greenhouse can be made not only from wood or metal profiles, but also from window frames, five-liter plastic bottles (which make excellent mini-size glasshouses), large barrels and other improvised materials. If everything is done correctly, then such facilities will be no less effective and practical than the standard stationary options.

- When developing a project for a future greenhouse, it is necessary to take into account all its dimensional parameters. Thus, the optimal length is a mark of 4 m.

- If you are interested in what kind of carrot, cabbage, dill and other similar greens will be the most comfortable, then you should know that low stationary constructions are best for these crops. If you plan to install the building with heating, then inside them you can safely plant tomatoes, peppers and eggplants.

- For cucumbers, separate beds are usually constructed, the height of which corresponds to the height of the plantings themselves. Experts recommend making custom-made designs for such vegetables - in the form of a tent.

- Working with wooden elements, we must not forget about their high-quality processing.Environmentally friendly material must always coat with antiseptic impregnation, so that he served as long as possible. If we neglect this rule, the wooden structure will soon begin to crack, rot and collapse. Moreover, it can become a tasty morsel for insects that harm not only itself, but also the landings inside it.

- Do not be afraid to use the most simple and cheap materials for the manufacture of country houses.

This will not adversely affect the quality of future construction, especially if you have done all the work correctly.

- It is not recommended to make too long arc-shaped covers. A rather shaky and unstable structure can collapse under strong wind gusts. To ensure the construction of additional strength characteristics, it is recommended to fix special vertical supports in the center of the extreme elements.

- Do not count on the long-term operation of greenhouses with film coating. It is likely enough for just one season. In addition, such a greenhouse will need to be treated very carefully, in order not to accidentally tear the film.No less carefully should be treated to models with glass trim, otherwise the glass can simply crack or break. Of course, it can be easily replaced, but it will take extra time and money.

- Do not forget that high-quality ventilation should be present in the greenhouse. For this, it is permissible to simply open the door of the building. It is recommended to do this when the weather is warm enough.

- It is necessary to place a greenhouse on the site in such a way that it remains lit throughout the daylight hours. Only in such conditions you can count on a rich harvest.

- If you decide to build a special greenhouse-thermos, which is permissible to operate all year round, before digging the pit, you will need to carefully remove the top fertile soil layer from the marked area. Removed soil should be moved to the side. Then it will be needed - it will need to be used when organizing the beds in the greenhouse.

- If you decide to put a greenhouse on the base of a wooden frame, then you must pre-mix it with antiseptics and place it on a “pillow” of sand.

- Consider the distance of the tracks between the beds, developing a plan for future construction. Remember to take care of plantings should be as convenient as possible - access to them should be free.

Examples of finished buildings

Homemade greenhouse can act as a decoration of landscape design. Of course, many owners are not so important appearance of such a design. However, no less people tend to supplement their plot with a beautiful structure that attracts the attention of guests and neighbors. Consider a few good options.

- Simply stunning on the site will look a high duo-pitch version of a greenhouse made of frames painted with white paint. Its lower part can be supplemented with gray brick or stonework. It will be possible to give a greenhouse a more vibrant and colorful look with the help of hanging pots with rich flower plantings mounted on the walls.

- Greenhouses made of wood can look attractive, even if they are not painted and do not complement the various decorations. Moreover, even in combination with a filmy covering material, they can look beautiful. So, small "houses" with gable roofs from smooth and well-treated boards will be a good solution for a green area with well-groomed grass.

- A metal arched greenhouse with a white frame and a covering material - polycarbonate (spunbond cloths can be used) will look great in a small summer cottage next to high floral plantings.

How to make a greenhouse for plants with their own hands, see the following video.