What should be the foundation for a garage?

Today it is difficult to find a person who would start building a house without a foundation. His role in the construction of virtually any building is very important, it is difficult to overestimate. And for the garage as a home for a car foundation is a must-have attribute.

Every car owner wants to have a garage. And if you can not buy it, then you want to build with your own hands for sure. Especially this idea is liked by owners of private houses or cottages with large plots of land. Such buildings are usually located outside the city, the role of the car increases significantly, and with it the need to have a garage.

Special features

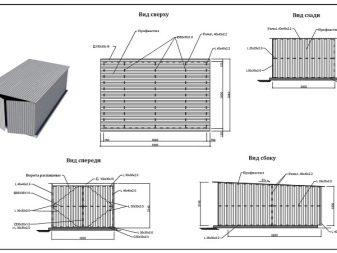

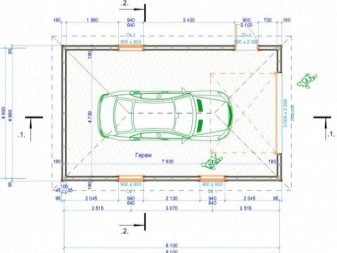

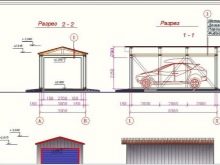

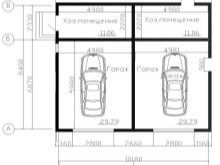

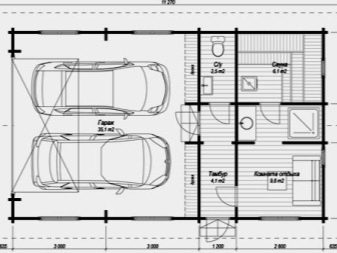

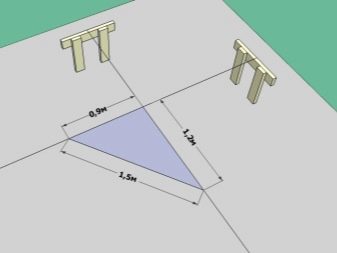

If we talk about the features of building a garage with your own hands, you should clearly understand how you want to do it. It is necessary to make drawings of the future construction, in which everything should be painted to the smallest details.After that you should choose the type of foundation that will form the basis of the future garage, and make the necessary calculations.

Here it is important to understand that even a small missing part can cause inconsistencies in the calculations and be the cause of the destruction of the garage.

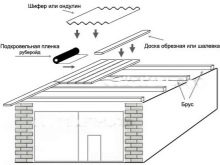

For example, many of those who build a garage forget about the weight of the roof during the calculations, which causes errors in the technical documentation, incorrect selection of the type of foundation, incorrect distribution of loads, and so on. And already at the construction stage, it turns out that the garage cannot be exploited, and the money spent on construction is simply thrown to the wind.

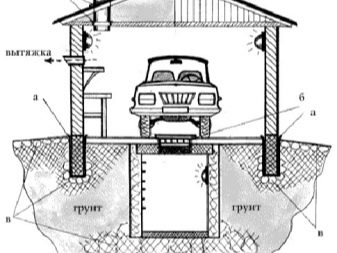

Another important feature is that you need to clearly understand why a garage is needed. If it will be only a car, it makes no sense to make it too spacious. If he performs other functions, then the dimensions must be appropriate.

What should be the depth?

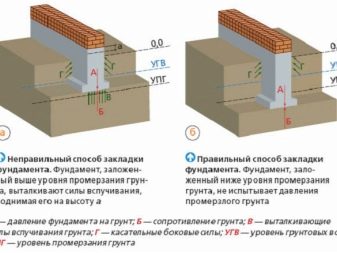

An important question when creating a foundation for a garage is a matter of depth. It is clear that the larger the foundation, the better.But its construction is a rather costly process, for which reason I want to do everything to spend less resources and get the best result. It should be said that the foundation thickness will depend on the ground in which it will be built. The main criteria in this case are:

- soil type;

- height of rise of flood waters in the springtime, the so-called smoy;

- the height of the building;

- the need to build an underground room.

Soil analysis is usually performed using three actions:

- determining the depth of freezing of the earth in the cold season;

- sampling from wells;

- establish the level of rise of groundwater.

Based on these criteria, it is necessary to calculate the required level of immersion of the foundation in the ground.

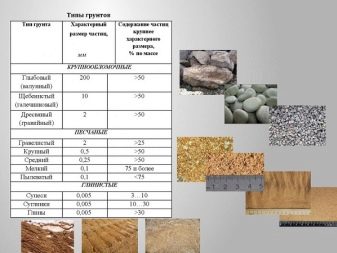

Naturally, the soils are different. The most common are:

- sandy;

- rocky, having an integral structure;

- peatlands;

- clayey;

- rocky, having a fragmentary structure.

The most reliable of the above will be rock type. As a rule, it is represented by solidified volcanic emissions and rock mixtures, which are tightly pressed to each other, which makes its array durable and solid.For such cases, you can even do without the foundation, since by itself such a soil can ideally become one.

If we talk about coarse gravel soil, it consists of gravelas well as various crystalline formations. This soil does not have a solid structure, and therefore there is a certain friability.

In this case, when working with a pit, you need to know that the foundation should be buried about half a meter into the ground.

Very common are sandy soils. And they are considered quite unfavorable for laying the foundation, as they have pronounced free-flowing properties, as well as are non-plastic. After permanent exposure to moisture and constant load, such soils tend to be heavily rammed. And in heaving soils of this type in general it is extremely difficult to build something. In this case, the recommended depth of laying will be somewhere in the 80 centimeters, on the basis that 40 centimeters must be taken to the foundation and another 40 to the pillow.

Extremely unfavorable are soils based on clay. The fact is that during drying such a soil can shrink, and in case of high humidity it can form landslides.When exposed to low temperatures, the soil simply swells due to its structure. In this case, it would be best to use the pile foundation, which should be laid 20 percent above the level of freezing at risk of flooding.

If speak about peatlandsthen this type of soil is also unreliable for creating foundation foundations due to the high content of various plant residues, as well as high humidity and uneven compression. For these reasons, to make a foundation on such a ground is almost impossible. If, nevertheless, the construction needs to be carried out on this type of soil, then it is best to replace it with sandy one, and then make a foundation of pile type. This is the only way out.

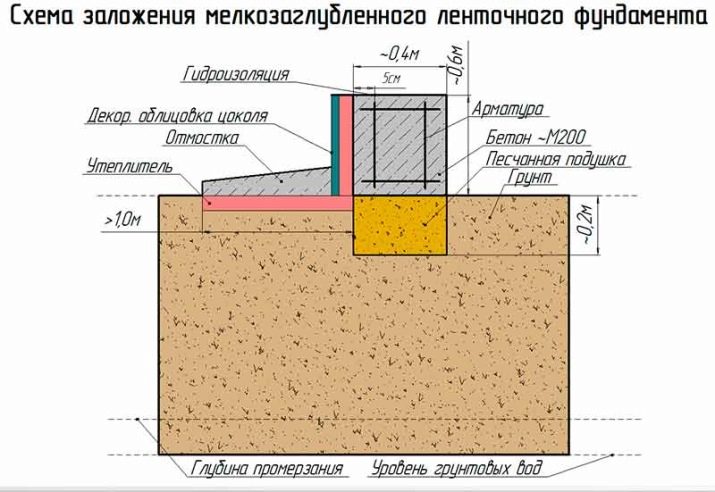

If the soil analysis cannot be done, or it is necessary to ignore it, then strip foundation is laid to a depth of not less than a meter. The size of the monolith width in this case is 40 centimeters. And in all the others - the weight loads are divided into the bearing properties of the soil. The resulting figure will be the minimum acceptable. When calculating it should be remembered that the thickness of the walls of the base of the garage will be slightly more than the size of the blocks.

Foundation types

As can be understood from the above, there are various types of foundation. The most common classification is as follows:

- columnar;

- tape

- strip foundation of the monolithic type;

- floating;

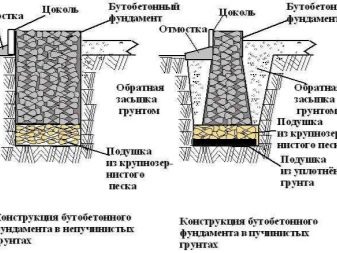

- rubble concrete;

- screw.

There are other types, but they are rarely used.

If speak about column foundation, which is also called pile, it is best to do it for a metal or frame garage. This will preserve the availability of the entire structure and ensure ease of construction. In order to make it, it is enough to measure the size of the module, and then determine the desired number of piles. Then you need to remove the primer under each pile. They can be made from various materials. To strengthen the structure it will not be superfluous to concrete these piles. And on top of the columns are already installed parts, which will subsequently be attached to the garage frame.

The second type of foundation - tape. This option will be more expensive than the columnar one, since it is more difficult to make it more difficult, and without a certain experience.First, a trench is dug around the perimeter of the future garage, then it is concreted. The last element will be strengthening the resulting structure to avoid destruction. Typically, such a foundation is created when the garage will be made of brick or heavy blocks. In certain cases, you can make a monolithic base plate, which looks like an ordinary slab of concrete, but is reinforced inside with a reinforced frame.

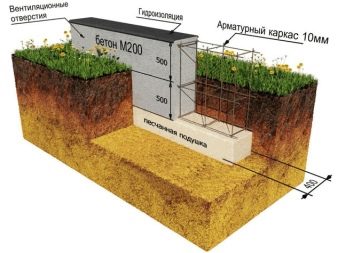

If speak about monolithic belt type baseIt is used quite often. Externally, it looks like a track, buried in the ground and copying the shape of the sole of the building. If this type is used for the construction of a garage, then it is sufficient to lay the foundation tape only along the outer perimeter.

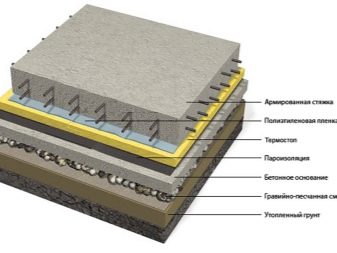

So called floating foundations they do it when the ground on which the construction will be carried out is unstable. In fact, this is a unique version of the monolithic slab, which lies under the entire area of the building. Such foundations would be an excellent solution in cases where it is required to build a brick-type garage or a building made of aerated concrete or stone on shaky ground.Often the basis of such a slab foundation is a reinforced concrete slab.

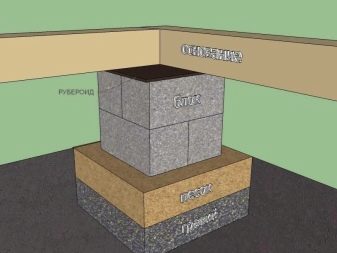

If the funds for the creation of the foundation a little, you can use rubble foundation. But only if the building is being built on strong and stable soil. It is possible to reduce the cost by using a rubble stone, from which the masonry is made, after which 5 cm of the soil layer is removed, and a foundation cushion is formed, thanks to the laying and tamping of 15-cm layers of sand and rubble. Further, all this is poured with a 15-centimeter layer of concrete, after which stones are placed on it. Between them there should be a distance of about 5 cm.

Now the construction is limited to formwork, after which a 25-centimeter layer of cement is poured.

Ribbon foundation is a structure of concrete and iron, which is located on a pre-planned perimeter. Such a foundation is made of brick material of concrete or gas silicate blocks. Or it may just be a concrete base.

Depending on the material used, the service life of such a foundation can vary from 40 to 150 years. If we talk about its benefits, it should be noted:

- simple construction technology;

- the basis suitable for different building materials;

- excellent resistance to temperature changes.

And if we talk about the shortcomings, it should be called:

- high cost of materials;

- difficult technology of construction.

As you can see, there are a large number of foundation types. The main thing to remember is that the main criteria for choosing the type of foundation are the type of materials used in the construction of the garage, as well as the type of foundation on which the building will be located.

Materials

Construction of the garage can be carried out from a variety of materials. The most popular today are:

- expanded clay or claydite blocks;

- foam blocks;

- cinder blocks.

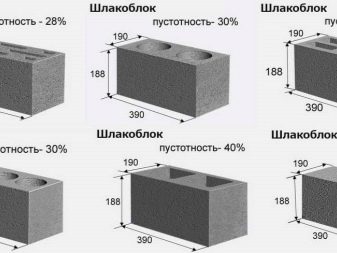

The latter are generally in great demand today for the construction of the foundation and walls of small buildings. For creating cinder block A special compound is used, consisting of ash, sand, slag and other materials. It is simple to put it, and at the same time it is very durable, and therefore is an excellent solution for creating a foundation. Slag stones are of two types - hollow and solid.But for the garage basement should be taken solely whole. It is beneficial to use them in the foundation for the following reasons:

- they are available;

- reliable and durable;

- speed of laying of the basis increases;

- reducing the cost of concrete;

- high refractory characteristics.

At the same time, such a foundation will have its drawbacks:

- it is impossible to use such material in loose or clay soil;

- the moisture resistance of the cinder block is extremely low;

- if the load on the cinder block is transverse, then its strength drops significantly.

Another popular option is the foundation of foam blocks.

When creating them, apply sand, water, cement, as well as a foaming agent.

The advantages of the foundation of foam blocks are:

- absence of harmful impurities;

- excellent sound and heat insulation characteristics;

- low shrinkage coefficient, as well as excellent resistance to moisture;

- good refractory properties;

- excellent resistance to environmental factors;

- small weight;

- low hygroscopicity;

- long service life;

- ease of processing.

At the same time, foam blocks have disadvantages:

- quite fragile, and when trying to bend, they quickly lose their strength;

- absorb moisture well;

- can be used for foundations only small buildings.

Also today you can often see the use of claydite materials to form the foundation of the garage.

Such material has the following advantages:

- excellent thermal insulation;

- good resistance to the effects of natural factors;

- after construction the building gives the minimum shrinkage;

- environmental friendliness;

- excellent radiation resistance;

- low cost;

- when exposed to high temperatures no harmful substances are released.

If we talk about the shortcomings of such material, it should be said that:

- material is extremely inconvenient to handle;

- blocks are easily destroyed when exposed to a dynamic nature;

- when using such materials, it is necessary to create heat-insulating and waterproofing layers.

At the same time, foundations can be made from other materials. Often you can find information that they are made using sleepers, bricks, gas silicate blocks, or even tires.

How to do?

Now, after it was told about the various materials for creating the foundation, its types, features and characteristics, attention should be paid to the issue of how to make a foundation with your own hands.This is extremely important, because if the construction does not go according to plan, then something will be impossible to fix. Suppose that we have already made a plan for a garage near the house, we were able to calculate what we need in order to complete the work.

Now we will tell about how to gradually fill the foundation.

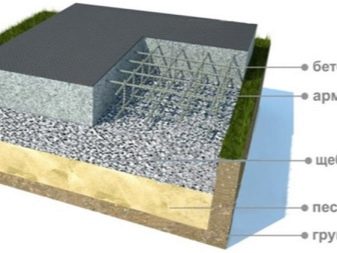

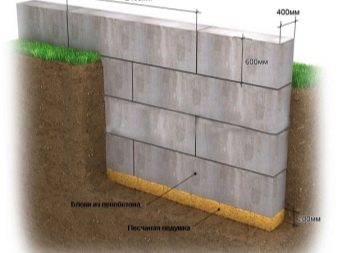

The first stage will be earthworks. Most often it is recommended to pour tape at a level of 40-50 cm. Typically, this figure does not include a so-called cushion, the thickness of which should be at least 20 cm. That is, the depth of the trench for the foundation should be 65-70 cm. choose arbitrarily. Before the direct casting of the mortar is carried out, it is necessary to make a formwork. In this matter it is best to focus on the size of the purchased blocks, as well as to know that the width of the base tape should be slightly larger than that of stones. In addition, there must be free space so that the frame shields can be reinforced with struts.

If the soil is not too dense, then the area of the structure support on the soil must be artificially increased. This can be done by increasing the width of the trench and pre-assembling the tie, which will then be put formwork. However, with this option, you will have to make the depth of the foundation more by the size of the thickness of the fill.

The second step will be the formation of the pillow. To do this, it is necessary to strengthen the bottom of the trench as much as possible, after which we put some clay in there and tamp it down. It is necessary to pour coarse sand on it. It is needed so much that after compaction this layer has a size of 1 m. Fine gravel is poured from above in such a way that its level is 1 m. The presence of a cushion will allow you to absorb the ground movement, if they will.

The third stage will be the creation of formwork. It can be done in various ways. Shields can be made of boards. The formwork height should be slightly larger than the fill depth. If the base is blocky, then it will be best to make the frame of a fixed type. You can either buy the form or make it yourself from the plates. Inside, such a structure must be wrapped with a film. It is necessary that the moisture is not absorbed into the wood, which can cause uneven concrete and reduce the strength of the building.

The fourth stage will be reinforcement. The parameters of the framework must be less than the depth and width of the fill.The armature itself should be at least 50 mm relative to the tape cut. In the case of coloring stone, the metal will begin to be exposed to corrosion. To prevent its occurrence, it is necessary to take special glasses made of plastic. Knitting is better not to weld, and do it yourself. It should be clearly understood that the frame should not only ensure the strength of the base, but also ensure the convenience of working with the solution. When working on the foundation it is necessary to take only metal reinforcement.

Any other options such as composite bar, though cheaper, but not suitable for reinforcing the tape.

The final stage will be the pouring of concrete, which is produced as evenly as possible by the size of the entire formwork. After all the concrete is poured, it must be sealed with a special vibrator, which will allow you to be sure that its density will be maximum. It now remains to give time to the concrete to make it stiff, and to dry out as much as possible. As a rule, concrete hardens for about 10 days, and drying will depend on weather conditions.

Tips and tricks

There are a lot of recommendations on this issue. Here are some of them:

- It is best to plan the work in such a way that it will be completed in a day.

- Another tip is to use small fraction gravel as a filler for a mixture of concrete. The fact is that the solution, after the filling was carried out, will need tamping to squeeze water and air out of it. With large parameters, the tape for a garage cannot boast, and it is very, very difficult to make compaction by yourself with concrete manually and really of high quality, which is filled with coarse aggregate.

- Not less important advice - if the garage is being built during the cold season, then it is better not to drain the tape on purpose. Better let the solution grow independently without unnecessary interference. Only in this case, the foundation will be able to turn out to be really high-quality and durable, as was intended when planning.

- If you want to install a lift for the car in the future, you should calculate this in advance. If you just start using the lift without preliminary preparation and construction, then after a while any floor will start to deteriorate.

As you can see, you can make a foundation for a garage with your own hands.But this requires certain knowledge, taking into account the mass of factors, ranging from the soil to the material properties. But if everything is calculated correctly, you can get a really high-quality and durable foundation that will be an excellent basis for your future garage.

To learn how to dig a trench for the foundation, see the following video.