The details of the garage finish

Every owner of the car wants his garage to be not only a home for a car, but also a well-equipped workshop. The main association with the word garage is a place where it is not very clean and smells of gasoline. But thanks to modern materials, the garage can be transformed without putting any effort into it.

Special features

Thanks to the correct finishing of the garage, you can make not only a cozy atmosphere, but also create such a room design that will correspond to the direction of its use. This may depend on many factors, such as how many floors the garage will have. It also depends on how far from the house it will be and whether it is a built-in garage below the house, located in the basement or a separate building.

The modern market is a great opportunity to choose materials for decoration. They can be purchased at any price that suits the person and select the option that is suitable for finishing the room.With the help of selected materials, you can hide all the deficiencies, as well as transform a place for a car beyond recognition.

Selecting the lining, you should consider for which surface this or that material will fit.

The floors in the garage must be able to withstand very large loads. It is necessary to pay special attention to the decoration of the walls. It must withstand any shocks, as well as be resistant to various influences. The headliner must be made of a material that is resistant to evaporation.

You also need to pay attention to what should be the materials themselves. The decoration of the room must be fire resistant.. Indeed, in the garage are flammable substances and there is a risk of fire. It is also necessary that the lining is resistant to chemical elements.. It should not be sensitive to humidity and sudden temperature changes, especially if the room is not heated. Finishing materials should have a long service life, as well as aesthetic appearance.

Materials

There are many materials that can be used to finish the garage. Covering can be done as a professional sheet, clapboard, drywall, stone. To determine which one fits best, you need to look at them in more detail.

Concrete

Most often used for such premises is concrete. After all, he holds out better than others on walls made of brick or aerated concrete. It has great strength, is not afraid of fire, if necessary, on the concrete surface, you can easily carry out repair work.

But like any material, concrete has disadvantages. Its installation is laborious work, which consists in the preparation of the solution, as well as its application. It is necessary to possess certain skills in finishing work. Their absence can lead to cracking of the surface or even peeling of concrete. The second drawback is that such a process is considered dirty work, so at the end there will be a lot of cleaning, which not everyone wants to mess around with.

Drywall

The interior finish of the garage room can be done with the help of drywall. To attach it, you can use a special glue. If the surfaces have irregularities or it is necessary to warm the room, you can attach it using a metal frame.However, this option will take a little space and the room will decrease in size. For the garage it is better to take fire-resistant and moisture-resistant drywall, having a gray-green color and red marking.

GKLVO has many advantages. These include relatively low weight, ease of installation, low price. Compared to other materials, the room remains clean during finishing with sheets, and after it is finished, there is no need to spend a lot of time on cleaning. The material also absorbs moisture well. From it, if there is a need, you can make partitions mounted with an iron frame, and organize a workshop or a small warehouse.

Its surface can be finished with any material. Drywall is suitable for finishing both walls and ceiling.

Ceramic tile

This material is ideal for the garage. After all, high-quality tiles are water resistant and fire resistant. It makes the room tidy due to the fact that it is washed by any means and cleaned in just a couple of minutes.

If the tile is properly put, it will withstand any load, and also will last for a long time.

Facing is better to do ceramic or clinker tiles with greater strength. The disadvantage is that it has huge weight and great price.

Panels

The lining of the room clapboard is very popular. It may consist from a natural tree. Surfaces can also be finished with PVC panels or with OSB sheets.. This material is easy to install. If we consider wood panels, they also have many advantages. Among the advantages include a long service life, resistance to frost, environmental friendliness, a large selection of colors.

However, without the drawbacks can not do. Wood panels are prone to insect attacks, highly flammable, and also susceptible to the appearance of mold, also have a high price.

The advantages of plastic panels include such qualities as low weight, the ability to tolerate temperature changes, the ability to carry out installation work with their own hands without the involvement of specialists. Also, these panels have a low price and a large selection of colors.

The disadvantages include the fact that they are flammable and very fragile.

PCA

OSB sheets consist of layers of wood shavings that are large in size. For bundles, resin needles from pine needles or formaldehydes are used.

Sheets are divided into several types. OSP-3 is of high quality and has high moisture resistance. but OSP-4 is considered more durable, besides, it can be used for interior and exterior decoration. He is not afraid of changes in temperature, has a long service life, good sound insulation. However, it also has a strong flammability.

Modular coating

A completely new type of finishing material - plates made of PVC or rubber. They can be laid not only in the garage, but also on the site adjacent to it.

Modular plates have a lot of positive feedback. They can withstand any, even very low temperatures, are easy to install, have high strength. Installation is performed using special glue.

PVC panels have a rough surface, so using them, it is impossible to slip even on a wet floor.

Siding

Most often, this material is used to finish the brick room outside. Coverage siding gives even the old building beauty and appeal. Recently, however, it began to be used for interior decoration of garages, because it has many advantages.

First of all, I am glad that it is fireproof, durable and relatively inexpensive.

A rock

Often for facing garages using natural or artificial stone. This finish looks very nice, besides not afraid of any weather conditions, nor humidity, nor fire. However, its price is too high.

Floor device

Very often, people only need a garage to store a car, and therefore the presence of a viewing pit is optional. Then, when laying the floor, you can simply make a tie. This is not a very difficult process, and anyone can do everything with their own hands.

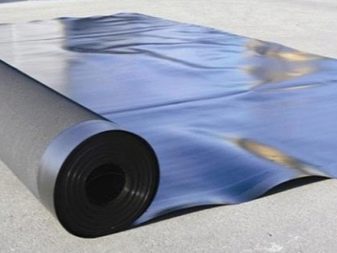

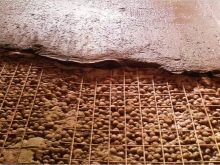

For this the first step is to level the ground with sand and rubble. Then a layer of waterproofing layer is applied. For these purposes, suitable roofing material. It must be laid overlapped so that the moisture of the concrete solution could not get into the ground. On top of the ruberoid, you can put reinforcing mesh for a more durable screed.

The next step is the installation of beacons, which is done by level. This will make the floor smooth. Then a concrete solution is prepared and poured onto the floor. Its components are very simple and widely available. It is ordinary sand, cement and crushed stone, whose proportions are 2: 1: 3 respectively.Everything is filled with water to get a solution of medium thickness. To facilitate the work, you can use a concrete mixer.

Fill must be done at once, so that the floor does not have cracks and is solid. The screed must be at least ten centimeters thick.. At its end, you need to level the surface well with the help of a building level. The drying process can last up to one month..

After this time, you can begin to finish concrete. For this suitable moisture resistant paint or marble chips. Ceramic, paving or clinker tiles that can withstand any load will be the ideal coating. Before laying it, it is necessary to treat the concrete coating with a primer., not allowing to absorb moisture from the glue, and only then proceed to laying tile.

If the floor requires insulation, you must make the flooring of the boards. For this, wooden lags are laid on top of the concrete. The space formed between them should be covered with expanded clay or polystyrene. If there is a basement or cellar in the garage, then a loose insulation is poured in and a reinforcing mesh is placed on top.This is done for additional insulation of the basement ceiling.

There is also a self-leveling floor. It is a very durable coating and is not inferior to anything in concrete. The main advantage is a completely flat surface. Its only drawback is the high cost. Therefore, most still prefer the concrete surface.

Wall decoration

Wall cladding in a garage is more labor intensive than laying the floor. To finish them, you can use materials such as drywall, tile, OSB, wall paneling, and plaster.

The most affordable option is considered to be plaster walls.. After all, it can be used not only to level the surfaces, but also to protect them from fire or temperature changes. This type of finish will suit walls made of foam blocks or aerated concrete.

In order to make the plaster surface evens, you must set the beacons. However, this process is very laborious and requires additional skills in work.

There is another option - ceramic tiles. Its main advantage is durability. Also, this material is not afraid of mold, which often appears on the walls after a couple of years.

Starting finishing, it is necessary to check that the wall surfaces are even. If not, then you need to plaster or cover them with tile glue and after that proceed to laying tiles.

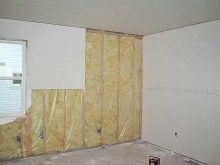

A more common way to finish walls is drywall or wall paneling.. In order to carry it out, it is necessary to pick up a crate, which can be both wooden and metal. If it is wooden, then Wood must be treated with antiseptic before installation.. This is done to protect the frame from rot and from rodents.

Then the sheets of a particular material are separately attached to it. Between the slats of the lattice in the free space fit insulation. You can use mineral wool or foam. but insulation thickness should not exceed the thickness of the rails.

The next stage is the installation of the vapor barrier. This can be a foil or ordinary plastic film. Then install the drywall or wall paneling. The first material is fastened with screws, and the lining method of the spike in the groove.

Ceiling

Ends the garage trim trim ceiling. There is practically no physical influence on its surface, so any materials will be suitable for finishing. They can be the same as for walls.

Using clapboard or drywall, you need to take care of a good waterproofing of the ceiling, without which materials can collapse, as well as make a well-thought-out insulation.

If the ceiling is made of wood, then you need to use a waterproofing film that is easy to install and also is inexpensive. For the concrete ceiling suitable special waterproof plaster. After that, the insulation is chosen, which not only makes the garage room warmer, but also prevents the appearance of condensation inside. This will keep the machine and the tools in the room in good condition.

The best way to do this foam. It is moisture resistant as well as cheaper compared to mineral wool. However, this material is afraid of the sun's rays, and also easily ignites. The cheapest form of insulation is a solution consisting of straw and clay.. He quickly fits, he is not afraid of fire. The only drawback is that it is too popular with rodents.

If the insulation is not necessary, then you can simply sheathe any panels.

Outer skin

There are many options for covering the facade of the garage room. The most common are siding, wooden paneling, sandwich panels.. Also for finishing the outside is often used such a method as a joint joints. It is one of the inexpensive options. For contrast, you can use different colors of the mixture. This method adds strength to bricklaying.

You can also finish the garage with plaster. It will not be very expensive, but if it is not visible from the inside, then from the outside, on the contrary, everyone will look at this “art”. Therefore, it is necessary to do plastering beautifully and efficiently. If a person has no experience, then you need to contact the specialists.

With this type of finish you also need to do the wall insulation, in this case it is called a wet facade. To do this, insulation is glued to the walls, and a reinforcing mesh is attached on top of it using polymer cement mortar. And only then finish decorative or facade plaster. The last step is staining.

Will look great wall sheathed with siding. In this case, you can not only choose the desired color, but also protect the room from the negative impact.After all, it does not crack, does not become covered with mold, is not afraid of bad weather conditions and is easy to assemble, so the finish can be made with your own hands.

Also today often used for the construction of garages frame walls. In their structure, the insulation has already been laid, so additional insulation of the walls will not be needed. The thickness of such walls should be about twelve centimeters.

However, if you plan to build a second floor, then you need to make walls up to sixteen centimeters.

To install such walls, you need to mount starting bars on the base of the base, which will be the basis of the frame. Before this, it is necessary to lay waterproofing on the base of the plinth. Then you need to attach the bars to the concrete with anchors at a distance of one to one and a half meters.

Then the installation of the remaining elements of the frame is done, with all the wooden surfaces to be treated with a special composition. After the completion of the installation work, you can proceed to the lining of the outer side, which must be completed with a gap for ventilation.

Covering can be done with wooden clapboard. This material is environmentally safe, however it constantly needs to be treated with antiseptics so that it remains durable and of high quality. And it will not be too economical.

Another costly option is decoration with artificial or natural stone. Such a facade looks very nice, plus it is not afraid of any exposure from outside.

Tips and tricks

Starting finishing the garage, you need to think through everything in advance. This is the external and internal decoration of the walls, as well as the arrangement of drainage and ventilation. So that the water from the rain and snow does not stagnate on the roof, it is necessary to make it with a slope and attach the guttersso that the water does not flow down the walls.

Also don't forget about ventilationbecause the garage can be filled with gasoline vapors and other harmful substances entering the air. Therefore, it is necessary to take care of such a ventilation system that provides air circulation not only in the garage, but also in the basement, if there is one. This will protect the walls from mold and mildew. And this often happens in an unheated room.

Do not forget about the internal equipment of the garage.This includes the arrangement of a viewing pit, and covering the walls, floor and ceiling, and decorating the room near the entrance.

If there is a basement in the room, then it will be enough to build a ladder with a slight slant, which will make it possible to carry out repair work. If there is none, then when arranging the inspection pit it is necessary to take into account the level at which the groundwater is located. They must be at least two meters.otherwise the liquid will accumulate in the pit. It is better to use concrete to finish the floor. It will be cheap, plus everything else such a finish option is almost not subject to destruction.

You need to know that the concrete absorbs gasoline and other liquids in the garage. To avoid this, it is necessary to treat it with a special impregnation.

You can also use ceramic tiles, however this will be a more costly option. True, he has more advantages. It will last longer, plus everything is not exposed to mechanical stress. Also, such floors will be easier to clean.

The decoration of the walls must be taken seriously. Choosing materials you need to watch,to meet the special requirements of the garage room. This fire safety and moisture resistance. It is better to choose as finishing plastering. It can also be used for finishing inside a hardboard or chipboard. With the help of them you can quickly cope with the work, as well as they are less flammable than other materials.

Do not forget about the device wiring, as well as lighting in the garage. It should be made so that the light spreads evenly throughout the garage. Also, if possible, leave space for a workbench and shelves with tools.

Beautiful examples

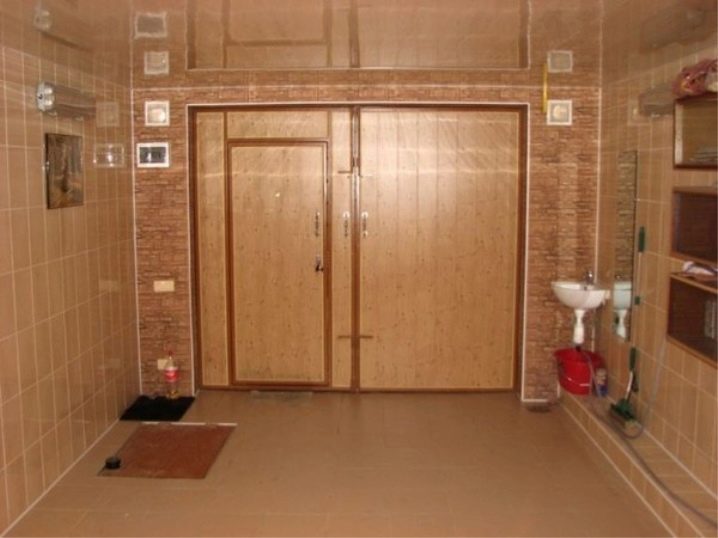

For finishing the garage, you can use ceramic tiles. It is perfect for walls and ceilings, as well as combined with tiles on the floor. This coating is very durable and reliable, and also looks quite nice.

Also for plating garage space you can use plastic panels. They look great on walls and ceilings. The floor is tiled, the tone of which creates a contrast to the white color of the panels. Inspection pit closed plate for safety. There are shelves for the necessary tools on the central wall, and wheels near the side walls.This garage is not only convenient, but also looks beautiful.

The third example is also neat and beautiful. Here the walls and ceiling are finished with plaster and then painted in color that is in harmony with the floor. Small windows give very little light, so the artificial lighting adds it to the entire room.

Having considered all the subtleties of the garage, it is safe to say that even an inexperienced person can cope with such work. However, it is necessary to listen to the advice of specialists, so that everything is done at the highest level.

To learn how to warm and clapboard the garage, see the next video.