Features harpoon mounting ceilings

Stretch ceilings have long been transformed from a luxury item into an integral part of modern renovation. Initially, they were used in cases where it was too difficult to hide flaws and surface defects. In contrast to suspended ceilings, the tensioning structure uses much less space due to a special fastening system.

Stretch ceiling successfully combines the properties of a thin and at the same time durable canvas, as well as a light but reliable frame, fixed on the ceiling or wall. The operational properties as well as the service life are determined precisely by the method of fastening.

Special features

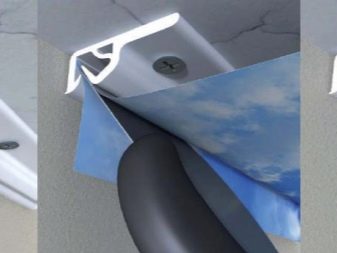

The harpoon is a special PVC profile that has been reinforced to give it extra strength and elasticity. It is used to fix the tensioning sheet in an aluminum baguette, which is attached to the wall.Before stretching the web, the profile is attached along the perimeter of the entire section where the installation is carried out. The harpoon is fixed by welding, which results in a high strength indicator.

Depending on the manufacturers, the shape of the harpoon profile may vary. Often it is a plate with protrusions resembling hooks, which can be more than one if necessary. To carry out high-quality installation, this plate must have high rates of flexibility and elasticity.

Pluses harpoon fixation system

In many ways, the harpoon fixation method is superior to the staple mounting system. Choosing what to use: a harpoon or a bead, It is worth paying attention to the advantages that the harpoon system of fastening the tension fabric.

- Installation speed Harpoon mount significantly reduces the time to install the tension cover up to several hours.

- The surface of the film is not subjected to stretching, thus avoiding the formation of folds after installation.

- Increased load capacity of the system in comparison with analogues.Due to the fact that the structure is able to withstand high pressure in the event of flooding, it is not necessary to change the web.

- The simplified dismantling system allows you to remove the cover, if necessary, and then reinstall it.

- The mounting design allows you to optimize the space between the ceiling and the tension coating, thereby allowing installation to be carried out even in rooms with low ceilings.

- Hidden installation allows you to achieve a more aesthetic result. During installation, a rim is formed between the wall and the baguette, which is easily masked by a decorative insert.

- The harpoon method allows for the installation of blades of various shapes, while maintaining the level of the ceiling.

Mounting tension cover

To achieve the best possible result of the installation of the tension fabric, one should carefully approach all its stages. By carefully following the procedure and observing all the necessary actions in the right sequence, you can make sure that the installation of the tension fabric with harpoons is not difficult.

At the first stage, the room where the installation is planned is measured. The main parameter in this measurement is the perimeter of the room. Due to the fact that the welding of the harpoon to the web is carried out at the production stage, measurements should be made with particular accuracy. For their implementation it is possible to use roulettes (both laser and metal) and construction level.

The use of the latter is most important, since it is the level that will allow to obtain a smooth and even surface of the tension sheet in the future.

The second stage is the cutting of the canvas, which will be further tightened in the room. It is cut in accordance with previous measurements and is equipped with a polymeric harpoon insert.

The next step is the installation of the aluminum profile in the places that were noted during measurements in terms of level. Manufacturers have equipped special holes for fastening on the profile, therefore, in the right places in the wall with a drill, they make holes and fix the profile with dowels and fasteners.

At the fourth stage, the harpoon is mounted into the corresponding groove using a special spatula. At this stage, the canvas is distributed under the ceiling.To align it is heated with a heat gun.

At the last stage, the gap between the wall and the profile is closed with a special decorative insert. Also in the ceiling are cut special holes for mounting the lighting system. Regardless of which system was chosen: harpoon or staple, When installing a stretch ceiling, you must comply with the technology and carry out thorough preparatory work.

In the event that you think over all the details in advance, draw up a plan and prepare well, you will get a result that will please you for a very long time.

Installation of PVC stretch ceiling with harpoon installation system, see in the video below.