How to cut tile tile cutter?

During repair, when all the dirty, rough work is done, it is worth thinking about finishing the floor, walls and ceiling. Many stop their eyes on tiled lining. Tiled, as well as tiled, is one of the oldest, but no less practical coatings. Today, tiles are made from a variety of different materials, for example, from ceramics, cement, stone and, in some cases, even glass. Any tile, regardless of the material from which it is made, requires special care.

Facing the walls or the floor tiles, it is almost impossible to guess with the size of the covered canvas, so fragmentary styling is still in great demand.

The peculiarity of the tile is that in capable hands it will be the best choice in finishing any room, be it a kitchen, a bathroom, a toilet or, for example, a garage.

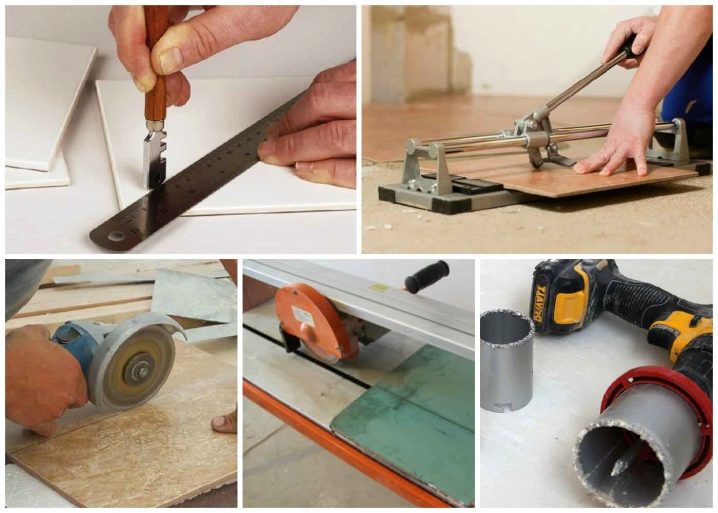

The tile is very wear-resistant and durable material, however, when figured cutting there are frequent cases of splits and cracks, which leads to the complete unsuitability of the canvas. Manually, without using any special tools, it is impossible to make a tile cut ideally even. To save your money, time and effort, consider all possible options for cutting ceramic products.

Glass cutter

For the first, the cheapest and clumsy way, you will need an ordinary manual glass cutter, which you can buy at any hardware store for 100-250 rubles.

This option is suitable only for thin tiles. This method involves the use of the ruler, glass cutter and patience, but, despite all your efforts, avoiding marriage is quite difficult: the tile tries to slip or move out from under the arm, thus making the cut uneven, and in places of strong displacement a split is possible, which will make the tile unsuitable for use.

For a proper cut, a deep scratch is made on the front side, which will then become the place of tile refraction. With this method of cutting it is very easy not to calculate the pressing force: a strong pressure will instantly crack a tile, and a weak pressure - a fracture curve.

Also, the tile can be incised with a nail on the same principle, but this method can only be used from despair, when nothing else, even a banal glass-cutter, is at hand.

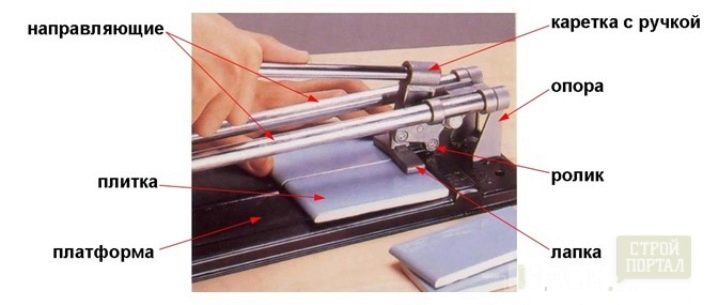

Manual tile cutter

Among builders of amateur and professional level, the most popular is the method of cutting tiles using a manual or machine-mechanical tile cutter. This method is relatively inexpensive, but no less effective than the operation of an electric tile cutter.

Tile cutting, depending on the level and quality, costs an average of 300 rubles. It can be found cheaper, but the quality of such a tool is fully consistent with its low price. It is worth noting a number of other advantages of this tool:

- Maximum security. Even the smallest member of your family will not be able to be injured by such a tile cutter, unless it falls on itself.

- Easy to use. Many who have never used such a tool before have noted that mastering cutting technology takes on average 10-15 minutes. The quality of the cut is not much different from the professional level.

A manual tile cutter is considered as simple as possible. It uses a movable handle, at the end of which there is a cutting element and tabs that break the tile. The main surface of the tool has a shallow recess, with the help of which the fracture is obtained as smooth as possible.It is very simple to prick tiles diagonally with the help of a manual or machine mechanical tile cutter.

The first thing to do is to secure the tile and prevent it from slipping. Fix should face to the handle. Then, without making much effort, hold the handle on the tile surface, forming a risk. The last action is to apply some force with the paws, which will cause the tile to break along the cutting line.

However, it is worth noting that a mechanical tile cutter doesn’t actually cut anything, but only makes a thin scratch or risk that violates the integrity of the face tile coating. This makes it possible to take a tile for a break in the required place, without obvious damage in other places.

The main disadvantage of this tool is that it will be extremely difficult to make an incision and then a tile edge less than 5-6 cm, which is a determining factor when choosing a cutting method.

Bulgarian

Cutting tiles with the help of grinders and circles on the stone is not less popular type of work than cutting with tile cutting.

This method greatly accelerates the work, but at the same time, cutting the tile, you get a lot of dust, so this method is suitable for well-ventilated rooms, and for work carried out in the fresh air.

Professionals choose this method with large fronts of work, where more even cuts can be neglected to suit the speed of finishing and repair.

To cut a tile or tile using a grinder, we need:

- Bulgarian;

- diamond disc for cutting stone;

- pencil and ruler.

Before starting work, you should take care of the respiratory system and eye protection.

To cut it is necessary to make measurements, and then walk along the line with a grinder, without exerting any extra effort. The Bulgarian should smoothly slide on the tile, otherwise chips are formed. Repeating the same action several times, you will achieve a perfectly flat cut. It is worth noting that The grinder should be pressed to the opposite side from the notch. This will help minimize the number of chips.

Many professionals advise to make cuts in weight, then the extra vibration will be extinguished by the hands, and an arbitrary split will not occur. This method is good because the irregularities obtained during operation can be polished using the same grinder.

Electric tile cutter

The best solution is undoubtedly the use of an electric tile cutter.This is a full-fledged professional equipment that will not only increase the speed and quality of the work done, but also increase your convenience. Such a tool can be considered a complete machine: it is energy-intensive, massive and demanding of service.

But despite all this, electric tile cutter is a leader among builders of any level - from amateur beginner to professional. This method, despite its complexity, is considered the most productive and qualitative than its counterparts.

In the electric tile cutter there is the same device as in the mechanical one. However, instead of a cutting element, like a nail or blade, this machine uses a saw blade, similar to that used in the Bulgarian.

When working with a large number of tiles, it is worth thinking about cooling the working surface of the saw blade with water.

Figured tile cutting

Very often for the design of protruding angles, an incision in the shape of the letter “g” is necessary. Many fall into a stupor, because tile cutter cuts tiles strictly in a straight line. The simplest solution is to divide the working surface into two parts.The first drank is made perpendicular to the long side of the tile, and the second - in parallel, thereby we avoid the formation of a terrible seam, which is formed by the addition of two tiles in the shape of the letter "g".

You can also try to cut with a glass cutter and pliers. The glass cutter makes a sufficiently deep risk, along which further breakdown is performed with the help of pliers.

I washed down the tiles at an angle of 45 degrees is no less frequent practice than a figure cut. If your tile cutter has an inclined mechanism, then such a cut will not be difficult, but if there is no such mechanism, you should not be upset.

Washed down with tiles can be made with the help of the same Bulgarian "by eye". Grind while keeping the tool slightly tilted. This was washed down is very often needed to hide the external, protruding corners of the walls, but this method is not recommended for rooms with slippery floors. It is safer to use curbs that will make the angle less acute, but it will not spoil the perception much.

How in house conditions to cut tiles at 45 degrees, see the following video.

Conclusion

Tile is one of the most popular ways of design and decoration of buildings, and is considered the most practical option than its counterparts. Initially, the tiles were made of clay and covered with glaze. Now manufacturers are not limited to clay, but use stone, ceramics and even glass, although the production technology has not changed much.

Selection of the required size and shape of the tile is achieved by cutting it. For an ordinary person who is not associated with the construction industry, cutting tiles is a difficult, painstaking and not always successful process. However, in fact, anyone can handle it.

The choice of instrument depends on the goals and type of work. A cheap manual tile cutter and a Bulgarian would be suitable for an apartment renovation, while for larger-scale works, an electric tile cutter is indispensable. The process of cutting tiles is not complicated, however, you shouldn’t hope for good luck and better buy some more material. This will eliminate the need to run, pick up and buy more missing.

The appearance and quality of the work depends on the correct and accurate cutting of the tile.