Drywall Planer: Specifications and Use Cases

Recently, due to the development of technology, the number of materials used in the construction and repair of apartments and houses has dramatically increased. This allows the use of previously inaccessible design and architectural solutions. One of these materials, which received today deserved popularity and is the leader among them, is drywall.

Different characteristics of materials determine the use of different tools and methods for their processing. In particular, special planers are used to work with drywall.

Material Features

The popularity of the use of drywall in the interior design of both domestic and industrial premises, due to several properties:

- availability of materials from which drywall and its low cost are made;

- easy creation of various frames, niches, partitions due to ease of processing;

- easy installation of structures;

- good physical and technological properties of the material, its resistance to moisture and temperature.

Production of several types of drywall due to the need to use it in different rooms under different loads. Consider the main types of material.

- Normal gypsum plasterboard (GCR). The most popular and used type, suitable for installation in any room.

- Refractory plasterboard sheet. It has a higher resistance to open flame due to the special composition, it is used for decoration of premises with increased requirements for fire safety.

- Sheet with high moisture resistance. It is made with the addition of silicone and special anti-fungal mixtures, most often used for finishing bathrooms, bathrooms, garages, and sinks. To achieve a more sustainable effect, it is recommended to cover the sheet with moisture-resistant paints and varnishes.

- Combined drywall options.

The standard is the thickness of the drywall 9.5 mm, however, with a thickness of 12.5 mm, the material becomes more durable, though heavy.

Given the characteristics of drywall, when choosing it, you should take into account the loadwhich will fall on the wall or ceiling, the possibility of mechanical stress, operating conditions (temperature, humidity).

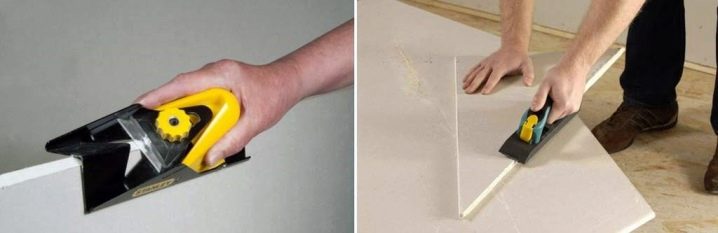

After cutting the sheets, the edge of the drywall is, if necessary, subjected to processing with a special tool in order to align and sand it, and also to give the necessary shape. This is what plasterboards are used for.

Tool types

Processing by a plane is applied to the edge of drywall, which is available in several forms.

- Bevelled, longitudinal, refined. It is intended for puttying of seams or gluing together with reinforcing tape.

- Rectangular edge. Used when joining dry, without any finishing seams.

- Longitudinal edge with a visible facet. Designed to create patterns on the surface along the seam.

- Rounded edge. It is used in case of processing compounds with plaster.

- Semicircular, beveled in length, refined. In the case of putty seams and gluing with reinforcing tape.

- Cross reinforcing edge. For putty compound without the use of reinforcing tape.

When processing the edge of drywall mainly used two types of planers.

- Peeling. It is a steel block with two handles, the bottom of which is a metal grater made of hardened steel. The body is made of steel or silumin, the handles are usually plastic. Used when sanding the edges of the drywall edges in joints with an angle of 90 degrees.

- Edged. It is a tool with two knives installed at an angle of 45 degrees (in some models and 22.5 degrees). When you purchase a planer, you must choose products with high-quality knives, otherwise after a while they will appear jags. It is used for chamfering at the given angles.

When choosing a model of edge planer, special attention should be paid to the location of the handles and the convenience of holding the tool in your hand, since this affects the quality of the edge to be processed.

Knives should be replaceable, which will replace them if necessary. When choosing a roughing planer model, it is necessary to consider that for high-quality work a grater is needed with a width of 15 to 30 mm and a length of 15-25 cm. A grater too long or too short is very inconvenient in operation.

In some cases, if you need one-time processing of the sheetmake your own hands of thin metal, making a large number of holes in it with a nail. The reverse side, where the metal is arched out, and will serve as a stripping cloth.

In general, planes produced by different manufacturers differ in several ways.

- The material from which the body is made (plastic and metal). The first is fairly inexpensive, the second is more durable and durable.

- Handle material (plastic, wooden, metal).

- The ability to change blades and adjust the angle of processing with special screws.

- The quality of the material of the blades, which affects the result of the processing of drywall and durability of work. In particular, the blades are made of tool steel or ordinary steel. Tool steel is more expensive, but it will last longer.

When choosing a tool and take into account the need to use it. So, if you plan to use it once or twice, then there is no sense in purchasing an expensive model. And if there is a need for long-term use, then you need to opt for the more expensive and durable models.

Processing the edge of the gypsum board, trim it and pay attention to the material cut left by the knives.It should be smooth, without chipping.

The presence of chipping indicates that the knife is blunt and you need to sharpen it or replace it with a new one. If after connecting the sheets between them there is a groove, then it is sealed, using serpyanka and putty, followed by grinding the seam.

Also, when processing the material with an edge planer, it is necessary to use a metal ruler or a corner as a guide to obtain the most even cut, since the edges of the sheet are rather fragile and it can crumble. Some models of planes for this purpose are already equipped with angles and rulers.

Browse popular models

Consider some of the most popular options.

- An interesting model is the edge trimmer for Stayer Profi drywall, which allows you to cut the edges of the sheet at angles of 22.5 and 45 degrees. Blades are made of high-strength steel, which guarantees the quality of processing. Also in this model of a planer, it is possible to adjust the blades depending on the sheet thickness (9.5 mm, 12.5 mm and more than 15 mm). Durable blades enable the angular processing of not only drywall, but also plastics and softwood.

- Edging plane Fit 15025 Made of plastic, it is a very practical tool. It has knives with an adjustable cutting angle of 22.5 and 45 degrees. Adjustment of the thickness of the processed gypsum board (9.5 mm, 12.5 mm and more than 15 mm) is provided. The knife is made of tool steel, which ensures its long work without the need for replacement.

- Stayer Profi 18855 is edging plane and made of durable steel. It provides two knives installed at an angle to the surface to be treated. For convenient tool holding, two plastic handles are installed. Use of the tool for processing of soft wood and plastic is possible.

- Edging Planer Stanley STHT1-05937 Made of steel, equipped with a convenient plastic handle. The installed knife can be easily removed with the help of a clamping nut. This is an inexpensive and fairly reliable model.

- Planter "Kantenkhobel" it is calculated on processing of an edge of a sheet of gypsum cardboard. The design provides for a change in the angle of cut by 22.5 and 45 degrees. The world-famous company Knauf guarantees high quality products, and this model was originally designed for professional use.Ease of use and reliability attracts users to this model.

- Peeling plasterboard MTX 879165 Made of plastic and has dimensions of 250x42 mm. Mounts installed in it allow you to quickly change the working canvas. In addition, there are special holes for chip output. Can be used for plasterboard and plastics processing.

- Model of the roughing plane Intertool HT-3602 has a length of 250 mm, and the model Intertool HT-3601 - 140 mm. They are intended for leveling (peeling) the edges of drywall. The body is made of plastic. The width of the working surface - 40 mm. The design provides for a quick and easy change of working cloths.

To learn how to make a plasterboard with your own hands, see the video below.