Choosing a hand spray gun for whitewashing

Technical progress and the introduction into operation of various devices that facilitate this or that work, and relate to the repair work. Some modern tools are used in conjunction with materials whose use has been calculated for many decades. For example, the use of spray guns and whitewashing for surface treatment.

Special features

When the question arises about the finishing work relating to the ceiling in the room, there is a need for a convenient and effective tool that will help solve this problem.

Planning to perform works on whitewashing the ceiling or walls, you can use a roller or brush, but surface treatment in this way takes a lot of time, and the process itself will be associated with discomfort and various difficulties.

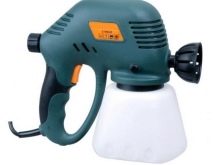

In order to optimize and facilitate such work, special devices for painting surfaces are presented on the modern market.They are called spray guns, some call this product spray, spray and so on. Spray can be manual, pneumatic and electric type.

The main feature of working with guns for painting is the level of security that they provide the master, because we all know that the lime mortar is quite caustic, therefore, in contact with human skin can cause a burn. When using a brush, such cases occur very often, and the use of the spray gun eliminates the presence of such unpleasant situations during the finishing works.

Liquid lime is quite difficult to apply to the surface a uniform layer without streaks, and the gun allows spraying in an even layer, processing even the most hard-to-reach areas.

The use of a mechanical airbrush for whitening does not require a stepladder, because Special fishing rods available in the device will make it possible to paint over the ceilings and corners between the ceiling and walls, while being on the floor.

Hand tools will save time required for painting,because their performance is enough to cope with a large working area, working on the principle of allowing to paint the base with minimal soiling and sprays.

As practice shows, a manual spray gun of 20 V, as well as other models of devices, with or without a shoulder tank, quickly and efficiently cope with the repair work in the rooms with their own hands.

The standard version of the mechanical whitewashing device is a small volume tank into which the coloring composition, lime, chalk solution or any other liquid substance is pumped.

The main component of the instrument is attached to the tank - a handle with a button that controls the course of spraying of the composition, the angle of application and intensity. In addition, the spray gun is equipped with a nozzle, from which the solution is released onto the base.

Today, you can find a large number of modifications of the mechanical tools used for the whitewash, they differ in their design characteristics and cost.

For industrial purposes, hand-held sprayers are rarely used, the main area of their application is operation in private houses and apartments.

Another model of manual spray guns is considered to be a piston tool, it is notable for its size and a slightly different principle for performing work.

In such a device, the injection of air is performed by analogy with a conventional pump when pumping. The cylinder contains several hoses, one of which is connected to the tank in which the composition for treating the bases is located.

The second hose at the end has a spray; it is an elongated metal tube with a button and a nozzle.

The advantages of hand-held sprayers include the following instrument qualities:

- simple configuration - the spray gun is very easy to disassemble, which allows, if necessary, to replace any parts that have become unusable;

- usability - any master will be able to regulate the supply of the train, even a person with minimal work experience;

- manual spray guns are universal devices that are suitable not only for working with lime and chalk, but also for any other type of dye for bases - the tool is recommended for use with any fine coloring compositions;

- products have a low cost, the most expensive device is considered to be a pneumatic spray gun;

- applied composition lays down evenly;

- there is no need to use additional devices in order to handle hard-to-reach grounds.

The disadvantages of the device should be attributed to the need to manually maintain the required pressure in the tank so that during the work a constant application rate was maintained.

Purpose

The spray gun is used for treating the working bases with dye compounds, lime mortars, stains, primers, or as a humidifier for surfaces using ordinary water. With proper selection of hand tools, with it you can do work with toners and nitrolak.

Manual sprayer many times better and faster to cope with the application of whitewash during the independent work.

It is right to evaluate the advantages of the device already in the process of whitewashing ceilings, since the main difficulties arise precisely in this area of the room.

To ensure the reliability and efficiency of the hand tool, it should be borne in mind that its design must meet the following requirements:

- a very important nuance is the weight of the device - during the work the specialist should not tire of the extra load coming from the sprayer;

- the holes at the nozzle must be of different diameter;

- The main structural elements should be made of a material resistant to wear and corrosion processes.

To ensure that the surfaces will be whitewashed qualitatively when using the sprayer, It is necessary to adhere to a certain technology of device operation:

- starting treatment, the tank must be filled with the composition only partially;

- after that, you need to remove the filter from the device and perform about 10 double stem approaches, this will help the device to fill with air;

- the exit of the liquid in a small uniform stream will indicate that the spray gun is functioning properly;

- protects the stock evenly and smoothly from excessive splashing; strong pressure should be avoided;

- when reducing the pressure level, it is necessary to bring it back to normal, since this may cause a layer of coloring matter that is too thick on the surface;

- At the end of the work, you need to disassemble the device and thoroughly clean all its parts.

Manufacturers

Manual spray for whitewashing used for a long time.Among the most popular models It is necessary to highlight the device CO-20B, KRDP-5 (4). Almost all products have similar characteristics, and the main difference is in the weight of the device and its cost.

An overview of the CO-20B manual spray gun is provided in the following video.

The manufacturers of hand spray guns are as follows Domestic and foreign companies: KSOM, Profmash, Auarita, Bosch, Einhell, Forte, Intertool, Miol.

Sprays allow you to work with lime and chalk solution in rooms where the ceiling height can reach 3.5 meters without using additional equipment, such as scaffolding or stepladders.

The design of nozzles is quite simple, so failures are the exception to the rule.

Experts recommend to give preference to domestic products, because the tools that foreign firms offer are often produced in China, so the sprayer body is made of poor quality plastic, as a result of which the devices have a short operational life.

The nozzle of the spray gun must be made of carbide raw materials, and the elements that will be in contact with aqueous solutions during operation must have a special protective coating that prevents the formation of corrosion.

Domestic products are manufactured taking into account all the above nuances, as well as in the tools there is an opportunity to adjust the extension for the paint supply on the basis of the height of the working surface, which facilitates processing.

Tips and tricks

Before buying a hand spray gun, you must clearly identify the purpose for which the tool will be used. Having decided on this issue, it will be much easier to make the right choice, since the range of modern tools is quite large.

Mechanical sprays are the most budget-friendly version of devices, pneumatic tools are expensive, electrical devices are in the middle price category.

The selection of the device is based on the following product characteristics:

- volume of solution tank;

- power;

- pressure.

Each parameter directly depends on the other - that is, a large tank will be distinguished by higher productivity. The optimal pressure is 5 bar.. Products often have a tank volume calculated for two liters of the composition.

Buy hand spray gun for whitewashing should be only from reliable suppliers that sell quality products.

New the solution should be pre-tested on any surface, before proceeding with the treatment of bases in the apartment, thus, it will be possible to once again be convinced of the appropriate consistency of the composition. Fluid before work is mandatory to strain. This will save time, because the sprayer will be clogged at times.

Efficiency and uniformity of processing will depend on maintaining the same spraying rate of whitewashing. At the end of the work, the remaining liquid can usefully be used as a means for treating trees in the yard.

Preparation for independent use of a spray for whitewashing includes the following points:

- on the size of the nozzle hole will depend on the efficiency and correctness of the application of the composition, so it is worth to adjust it, bringing it to the smallest size;

- to strain the solution, it is worth using a sieve, the cells of which will be no more than 5 mm, besides, gauze is perfect for such tasks;

- In order to extend the service life of a hand-made whitening tool, regular maintenance of the device should be carried out.

Experts recommend performing checks every month.

Besides, After each use, the instrument must be thoroughly cleaned. and conduct a detailed inspection for possible defects. For these purposes, a visual inspection of all structural elements is performed, after which the gaskets are checked, as well as the functioning of the device.