Rack ceilings Albes: varieties and installation features

Albes rack ceiling structures are well known in the domestic market of building and finishing materials and are a popular solution for ceiling design. The production of this product for 20 years has been carried out by the Russian company of the same name, which has managed to set up the production of high-quality steel and aluminum systems for such a period.

About company

Albes products are of high quality and long service life. The company has its own engineering group, which is engaged in the study and implementation of new technologies and takes into account all the wishes and comments of consumers.

The priority direction of the company is the production of products complying with strict sanitary and hygienic standards. This allows the use of rack structures for cladding ceilings in sports, medical and educational institutions. For each series of products there is a necessary accompanying documentation in the form of a quality passport and a certificate of conformity. The company repeatedly became the winner and the prize-winner of prestigious competitions of building materials, has a large number of diplomas and honorary diplomas.

Specifications

Albes ceiling is a suspended metal structure that has an aesthetic appearance and is easy to install. In the manufacture of panels used method of cold rolled sheet metal, followed by stamping blanks. The raw material for the production of rails is aluminum and galvanized steel. The thickness of the sheets does not exceed 0.6 mm, the length is 3-4 m, and the lamella width varies from 5 to 20 cm. Customized production of panels is possible, the length of which reaches 6 m, and the presence of special connecting elements gives the impression of their continuity.

The front side of the metal slats is covered with a polymer composition, which provides a wide range of colors and a wide variety of textures that mimic various materials.The surface under natural stone, patinated copper and wood looks interesting. Along with flat forms, the production of perforated surfaces has been adjusted, allowing to create interesting relief images and volumetric combinations.

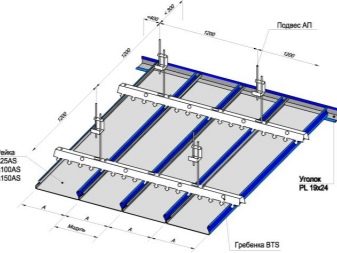

The fastening of the rails to the guides is carried out with the help of aluminum or steel combs having a thickness of 0.6 to 1 mm and equipped with a special locking structure made in the form of snap-on tongues. Elements of fastening structures such as suspensions, layouts and stringers are also included in the rack ceiling system. Fixing guides to the bearing surface is carried out with the help of spring hangers, which allow adjusting the arrangement of the lamellae and responsible for the reliability of fastening of the entire ceiling structure.

The perimeter frame is usually made of a U-shaped profiled iron PPP 18 or its modifications РL, thanks to which the necessary hardness of the ceiling structure is ensured, which ensures flawless service of the ceiling throughout its service life.

Benefits

High customer demand, numerous encouraging reviews and the growing popularity of Albes slatted ceilings due to a number of indisputable advantages of this material:

- Durability, increased strength and reliability of the design allow you to forget about repairing ceilings for a long time. With regular maintenance and compliance with the operating conditions, the service life of metal structures is practically unlimited.

- The excellent reflective qualities of some models allow you to visually lift the ceiling and make the room brighter.

- Attractive design and a wide variety of textures and shades allow you to choose a model in a room for any purpose.

- The high mechanical, chemical and anti-corrosion resistance of the panels makes it possible to use the material in rooms with high humidity, in workshops in production rooms, in unheated and condensation-prone spaces.

In the event that the panels are made of galvanized steel, the surface should be coated with an anti-corrosion solution.

- The installation of the rack ceiling in combination with the noise absorbing substrate will provide high heat and sound insulation qualities of the structure, significantly reducing the heat loss from the room and guaranteeing high-quality protection against extraneous noise.

- Absolute incombustibility of materials ensures complete fire safety of the ceiling structure, which increases the overall safety of the room.

- Easy to care. You can wash and clean the slatted ceiling by any means except for abrasive compounds.

- High environmental safety and hygiene products due to the properties of the material of manufacture. The metal is not subject to rotting, is not of interest for insects, is not prone to the appearance of mold and fungus. The surface of the panels does not emit toxic and toxic substances.

- Simple installation allows you to perform facing the ceiling yourself, without using additional equipment and without the services of professional builders.

- The possibility of embedding light bulbs and creating a multi-level curved design provides great opportunities for the realization of design solutions and the implementation of artistic images.

- The presence of the ceiling space allows you to install in this area any engineering equipment.

- The price of slatted ceilings is noticeably lower than the cost of other types of decorative ceiling coatings - this allows the material to be used forfinishing large areas, such as shopping and sports halls, swimming pools and industrial premises.

Species

Aluminum rail ceilings are available in several collections, each of which has a unique design, relief and style of execution.

- German series it is presented by slats from 8.5 to 18.5 cm wide. The panels have a rectangular shape, a strict and discreet design and are used for a closed installation method. The closed method involves a dense arrangement of the rails between them and the formation of a homogeneous surface. German models are available in a wide range of colors and can have both smooth and perforated surface.

- Italian series it is presented by the panels made of aluminum hire and having rounded edges. Expanded mesh models also belong to this collection. Italian ceiling is designed for installation in both open and closed way. The essence of the open method of installation is the formation of surfaces with a loose laying of the lamellae. The gap between adjacent laths can not be closed with anything or decorated with colored inserts.

The width of the interpanel space is usually 1.5 cm. Mesh models are mounted only in an open way. The Italian collection is made in restrained classic colors in a smooth or embossed design. The slat width is 8.4 cm.

- Omega Series it is presented by the aluminum panels which are not having lateral dredging and intended for the closed way of installation. The width of the rails varies from 5 to 15 cm. The presence in the collection of narrow slats allows you to combine several rails of different widths and colors, placing them on the same guide. This technique looks very impressive and is perfect for rooms made in high-tech, metallic, techno and minimalism.

- Curvilinear systems They are constructions characterized by smooth bends and transitions. The use of models of this series is an excellent solution for finishing uneven ceilings, as well as in cases when it is necessary to go around the elements of engineering communications or other obstacles. Models are manufactured on the basis of the Italian series and have a perforated undulating surface. The direction of the waves can be both longitudinal and transverse.

- Cuboid view it is presented by aluminum lamels with clearly expressed rectangular section. Due to this structure of the rails, the formed surface acquires a strict relief. The model is intended for open installation.

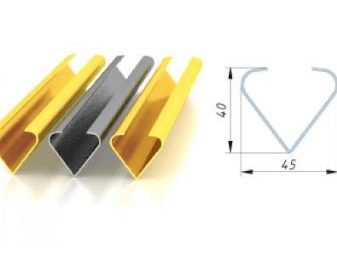

- V-shaped panels also used for an open installation method and give the surface a distinct geometric relief pattern. The height of the slats is 4 cm and width - 4.4 cm.

Color solutions

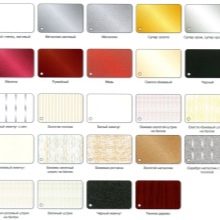

Albes products are presented on the modern construction market in a wide variety of colors. The color of the panel is formed by powder spraying during production and is coated on top with a polymer composition. Thanks to modern dyeing technology The colorized surface is not affected by UV light and is able to retain the original color throughout the entire life cycle. The most popular is white color, produced in matte and glossy versions, and metallic, also having two versions.

Chrome products with a smooth mirror surface are also popular.They are available in three versions: "chrome", "superchrome" and "superchrome lux". Mirror slats make the room much lighter and visually increase the space. Also popular is gold, beige and light beige. The most colorful options include black, blue, dark gray colors, as well as copper and crimson.

Combined models are also no less interesting. Golden stripes on a milky background or green strokes on a white panel look impressive. Popular imitations of natural materials: wood, pearls, granite and marble. The company is also engaged in the manufacture of slats according to customer sketches, taking into account the preferences for color and relief.

Installation

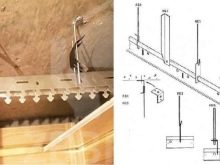

Before starting the installation of guide structures, the surface of the ceiling slab should be primed. In that case, if the work is performed in a room with high humidity, anti-fungal mixtures should be used for processing. After complete drying of the substrate, it is required to proceed with the marking for the corner profile, which is applied in a single plane around the perimeter of the room. For more accurate delineation, you must use a building level or laser.

Then, using a perforator, holes should be made in the angular profile in increments of 50 and at a distance of 5 cm from the edge. The angular profile is attached to the walls with dowels, after which the locations of the hangers and the guide profile are marked. Suspensions are mounted 40 cm from the wall in 1.5 m increments.

After installing the suspensions, you can begin the installation of the stringer frame construction in which the slats will be placed. To do this, hang the combs on the hooks with which the suspensions are equipped. Then the slats are inserted into their grooves and fixed to a click.

After all the panels are placed, you need to align the formed surface, which is carried out by tightening and loosening the suspensions to the desired length.

Albes slatted ceilings are a popular finishing material - they allow you to create a beautiful, durable and durable coating, as well as decorate the room and emphasize its style.

To learn how to install the rack ceiling in the bathroom, see the following video.