Ways to warm the ceiling in a house with a cold roof

Much has been said about the insulation of buildings in recent years. Russians massively rushed to insulate the facades of their homes and even the foundation. But about the ceiling for some reason, remember infrequently. And it is in vain, because the heat loss at home through the roof can reach 20%. Therefore, the arrangement of thermal insulation in the attic not only keeps the heat inside the house, but also significantly saves heating costs.

Special features

From a school bench it is known that hot air rises up, and cold air goes down. This is due to convection and leads to the fact that all the heat accumulated in the room, through the non-heated ceiling will get into the unheated attic, and then go out.Thus, the heating system of the dwelling begins to work on “street heating”.

It is for this reason that the insulation of the ceiling requires a more thorough approach than the insulation of facades: wooden heat loss reaches 3W / m2 / K, and for ceilings in a brick or concrete house this figure is even higher. That is why the insulated ceiling will be the best protector of the house in the cold season.

However, in the summer of its relevance is no less significant. Under the action of high temperatures, the roof becomes hot and transfers the heat inside the room, completely nullifying the effect of using air conditioners.

The heat insulation layer retains heat well, preventing overheating of the internal space.

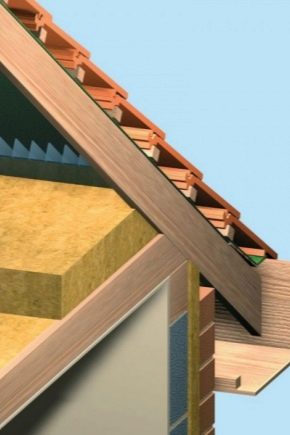

At the same time, most of the old houses have a cold roof, in the Soviet years the buildings were built quickly and simply, and there was no choice of reliable materials. The roof in such structures is, in fact, a system of wooden rafters, over which a layer of waterproofing and the main roofing material are laid.

Installation of a new insulated roofing structure requires a significant investment of effort, time, and most importantly, money, so not everyone can afford to dismantle the old roof and build a new one.In this situation, the optimal solution is the insulation of the ceiling, either from the attic or from the living rooms.

Another advantage of insulation due to its good sound absorption. Thus, the material will not only form a healthy temperature in the house, but also protect the household from the sounds of rain, hail or wind.

Once spent on attic insulation, you can extend the life of the entire roof structure in the house and significantly improve the microclimate in the living room for many years to come.

By the way, keep in mind that if the house has been made to warm the ceiling from the attic, then no additional warming of the floors on the first and second floors is required.

The better to warm?

Nowadays, the construction market offers a wide choice of various materials for insulation of the ceiling - from the most modern - mineral wool and polyurethane foam, to options for thermal insulation with clay, sawdust and hay that came from antiquity.

Each technology has its advantages and disadvantages. Let us dwell on them in more detail.

Materials

Practically any composition as well as all types of polymeric tile coatings, such as mineral wool and penoplex, will be suitable for insulation of the ceiling.

High-quality insulation should meet the following criteria:

- Any, even minimal release of harmful and toxic substances under the influence of high temperatures and ultraviolet radiation is unacceptable.

- The material must be hygroscopic, resistant to moisture, as otherwise its operating parameters will be significantly degraded.

- Insulation must be resistant to combustion - that is, it is very hard to ignite or not to ignite at all. Fire safety regulations require that the material used restrain the spread of fire for at least 25 minutes.

All types of insulation can be divided into several groups:

- polymeric materials;

- fiber insulation;

- sprayed insulators;

- bulk formulations.

The most popular materials for insulating the ceiling are given below.

Minwat

Mineral wool is commonly used in construction. Insulation parameters meet all the necessary technical requirements for insulation materials.

The use of wool in residential buildings due to its environmental safety - it is made only from natural materials (limestone, diabase, dolomite or basalt).

The advantages of the material also include resistance to the adverse effects of weather and flammability.

At the same time, mineral wool has its drawbacks, namely:

- has the ability to absorb water, so when installing it is necessary to lay a layer of waterproofing, and the seams should be additionally treated with sealant or foam;

- Laying requires a framework-crates, which leads to additional costs of effort, time and money;

- Fiber insulators have a relatively short lifetime - their efficiency is maintained for 10-15 years, and then the heat insulator needs to be replaced.

Ecowool

Ecowool is made from cellulose fibers. This material appeared relatively recently and is not yet as common as mineral wool, but it is obvious that this is only temporary.

Its advantages are as follows:

- This insulation has a small weight, greatly facilitating the installation work, and also contributes to more reliable thermal insulation of the ceiling.

- Ecowool is resistant to moisture, it does not appear mold and fungi do not breed.

- In addition, the fabric is subjected to special treatment with fire retardants, therefore it is considered to be a material that is resistant to fire - it is a low-combustible and self-extinguishing material.

- The coating that forms ecowool is dense and seamless, it is optimal for protection from the winter cold and summer heat.

Cellulose fibers are breathable products, so the insulation does not prevent the free circulation of air, contributes to the removal of condensate and the creation of a healthy microclimate in the room.

Penofol

Modern insulating material, which consists of polyethylene foam and aluminum foil. The covering is widely used when finishing not heated balconies and loggias.

The advantages of penofol are obvious:

- differs in the lowered heat conductivity, so, promotes economy of costs of heating of the house;

- prevents cold air and radon from entering a living room;

- has a low weight, which greatly facilitates installation and at the same time does not create an additional load on the floors and supports of the building.

However, the disadvantages are also significant. The surface of penofol is flexible, therefore a mandatory installation of the frame is necessary. It is not suitable for all surface types. Penofol is most often used together with mineral wool, this contributes to more efficient weatherization of the ceiling.

Styrofoam

Polyfoam, it is expanded polystyrene, is considered one of the most convenient materials used for thermal insulation of surfaces. It creates effective protection against cold and heat, but it does not harm the health of the inhabitants of the house. If installed correctly, the foam will retain its performance over the years.

Its advantages include:

- hygroscopicity;

- good thermal conductivity;

- low weight;

- ease of installation.

Among the minuses noted:

- weak burning resistance;

- exposure to UV rays and chemicals;

- instability to mechanical damage.

Polyurethane foam

By its chemical nature, PPU is close to traditional foam, its components provide good adhesion to surfaces of various types, however, special equipment is needed for the installation of polystyrene foam. Therefore, it is not possible to apply it yourself.

The coating, which gives the foam, smooth and seamless, there are no cold bridges. In a frozen form, the coating is completely non-combustible, exhibits thermal insulation characteristics that exceed the same indicator for polystyrene by 1.3 times.

The lack of polyurethane foam is due to the fact that it is destroyed by UV rays, therefore the installation requires additional protection from the sun's rays.

Expanded clay

This is a fairly common material that is very often used to insulate the ceiling in private homes.

Expanded clay is a porous granules made of clay. Such material retains heat well and can last much longer than any other insulation. Expanded clay is not afraid of water, resistant to fire and very durable.

The lack of expanded clay is associated with its weight - the material creates an additional load on the floors and the foundation of the building, so it can crumble only if the building is able to withstand increased pressure without sagging or deforming.

Other varieties

For finishing private houses in villages and cottages, they often use methods that came to us from ancient times.

Our great-grandmothers and great-grandfathers insulated their houses with materials of natural origin:

- sawdust;

- reeds;

- straw;

- needles;

- algae;

- with hay.

Warming with sawdust Perhaps, it is one of the most ancient ways of warming dwellings.Such variants of thermal insulation are widely used in the regions where the woodworking industry is well developed - there you can buy such material literally for a penny, and sometimes get it for free.

Its advantages are obvious - it is an environmentally safe raw material and low weight, and such insulation is very inexpensive.

However, the flaws are quite significant: sawdust quickly ignite and sustain combustion, eventually rotting or shrinking. And besides, rats, mice and other rodents may well "watch" fresh chips as a habitat.

Another option of warming that came to us from ancient times is the use of clay. It is not used in its pure form, to create an effective insulating layer, it is necessary to create a coating 50-70 cm thick. Not a single wooden material can withstand this load, which is why a mixture of clay and sawdust is widely used.

In the Soviet years, many used for warming a country house with slag and glass wool.

Slag wool is a material produced from blast furnace slags. This is a cheap heat insulator,However, in recent years, most consumers have refused to use it - it absorbs moisture, and when wet it creates an acidic environment, which contributes to the destruction of the elements of the roof structure.

Glass wool has not lost its relevance to this day. - this material occupies a leading position in the quality of thermal insulation between all types of mineral wool. This measure of material corresponds to 0.03 W / mK. Another advantage of the raw material is its low cost.

However, working with glass wool may be unsafe - particles of the material can damage the skin of a person and, if they come into contact with the eyes or lungs, cause serious injury. Therefore, working with this material requires the use of protective clothing - gloves, glasses, a raincoat and a respirator.

Required tools

To carry out attic insulation work, it is necessary to prepare all the required tools and materials:

- direct insulation;

- wooden bars or metal profiles under the crate;

- hardware products;

- vapor barrier coating;

- construction brackets;

- dowel;

- perforator;

- hammer;

- screwdriver;

- roulette;

- construction knife.

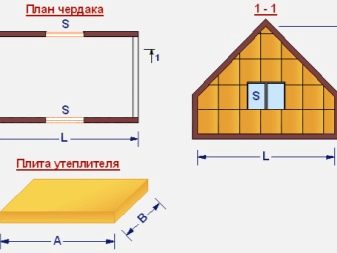

Calculation of the amount of insulation

A century ago, the width of the walls helped to keep the room warm — sometimes it reached 1 meter! Nowadays, the need to build such walls has disappeared, since a huge variety of materials for heat and waterproofing of buildings appeared on the market. Their density forms a lower thermal conductivity, due to which the heat loss of a dwelling is sharply reduced.

Therefore, today, when preparing the finishing works, a friend comes to the fore, the task is to save. That is why, before going to the hardware store, it is necessary to calculate well the amount of insulation that will be needed to effectively create the insulation layer.

The general formula by which you can calculate the required indicator is as follows:

V = L * g, where

V - insulation volume in cubic meters;

L is the calculated perimeter of the working surface in meters;

g - insulation thickness in meters.

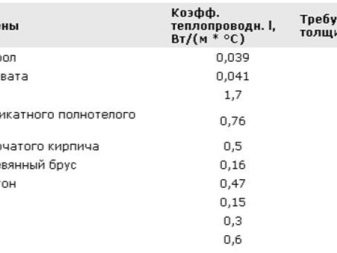

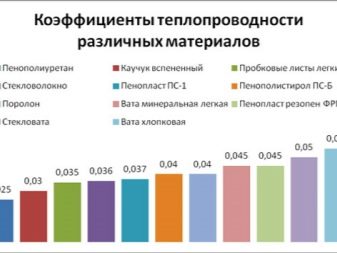

When calculating a given parameter, it should be borne in mind that the EnUV standard was officially adopted in 2009, according to which the heat transfer coefficient of the thermal insulation coating was at least 0.24 W / m2xK.This value is provided by a layer of insulation from 13 to 40 cm thick, depending on the materials used and the value of their thermal conductivity.

In addition, you should consider the type of buildings. For example, in European countries, various requirements are imposed on buildings of different types - for older buildings they are less stringent than for new types of buildings.

Preparatory work

Before the start of installation work on the insulation of the ceiling, it is necessary to prepare a wooden surface:

- to clear the place of laying of a heater from garbage and dirt;

- with particular care to treat all wooden elements with a fire retardant, which will enhance its flammability, should be very careful to apply the composition in the cavity of gaps, cracks and cracks;

- to eliminate all existing deformations and damage to the surface - small cracks are filled with a putty, and more serious damage is treated with assembly foam, the excess of which is then removed with a simple knife.

If the insulation is mounted on a concrete surface, the preparation looks a little different:

- inspect the ceiling, remove all flaking and fragile decorative coatings, and then remove dust;

- the detected cracks slightly widen and remove the dirt accumulated in them, after which they should be puttied or treated with a sealant;

- to treat the surface with a layer of primer.

Mounting technology

The technology of installing insulation on the ceiling involves the use of one of two methods.

- Warming from the inside - This is laying insulation on the ceiling surface from the dwelling, often accompanied by the installation of suspended structures or drywall. Particular attention should be paid to the fact that the total height of the ceiling with this method of installation will decrease by about 10-20 cm. It is very important that the material has good vapor permeability, to the greatest extent penofol, as well as mineral and basalt wool meet these tasks.

- Warming the ceiling outside - This is laying insulation from the attic. The option is quite profitable and practical, as it does not require any finishing finishing works (except for cases when the room is planned to be made residential with an attic). The most common materials for this type of installation are foam, penoizol, expanded clay and mineral wool.

The first option is considered less preferred for a number of reasons:

- the height of the ceilings is significantly reduced, which is already small in old private houses (standardly, during Soviet times, the height of the ceilings was 240-260 cm);

- inability to use bulk type heat insulator;

- cooling points move closer to internal ceilings;

- the need for repairs in connection with the analysis of the old ceiling.

If the attic is insulated outside, the installation is devoid of all the listed drawbacks. However, sometimes there are situations when the insulation outside is not possible, so we consider both options for laying the insulation layer on the ceiling.

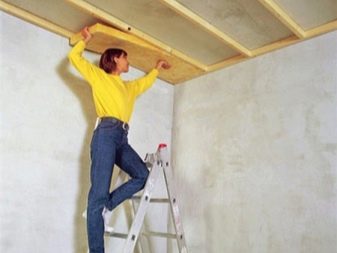

Inside

Insulation works from the dwelling are conducted in cases when reconstruction of old-style buildings with finished attic floors is being carried out or access to the attic is not available.

The overlap is insulated in one of the following ways.

The first involves the fixation of thermal insulation materials immediately on the floor with the use of adhesive solution and additional fastening with dowels.This method is optimal when the floor is made of reinforced concrete.

The sequence of works is as follows:

- overlap ground;

- prepare an adhesive solution;

- glue is applied to the plate of heat-insulating material, after which it is pressed against the surface and set in a horizontal direction;

- after the solution has mated (as a rule, it occurs in 2-3 days), the insulation is additionally fixed with dowels with a large cap.

At the final stage, the ceiling is finished.

The second method involves the installation on a frame base of wooden lumber or metal profile. At the same time, the insulation is mounted between the main bearing parts of the batten and mounted with bent straps of strong direct hangers.

The method is suitable for any type of overlap.

Both options are highly efficient, although the thickness of the coating is often significantly limited due to the desire to preserve the maximum useful space of the dwelling.

Outside

The method of insulating the ceiling outside is more preferable. It is not surprising, because this method does not steal the height of the ceiling.In addition, the method is good if the rooms have already made a high-quality repair, the interior is decorated and the ceiling is made in the form of a decorative stylish design. Then the inhabitants of the house often do not want to destroy the created "beauty" and spend time, effort and money on the equipment of the new coating. In this case, conducting insulation over the ceiling is most preferable.

The device of a thermal barrier in this way involves the use of materials of any type.

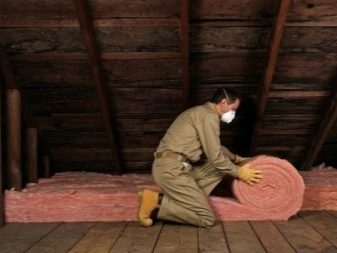

However, it should be borne in mind that working with ecowool and polyurethane foam requires the help of professional teams. But laying mineral wool, foam or expanded clay can be done with your own hands.

If the floor is made of reinforced concrete, then the best option would be expanded clay, covered with a layer of 15-20 cm or insulation of penoplex.

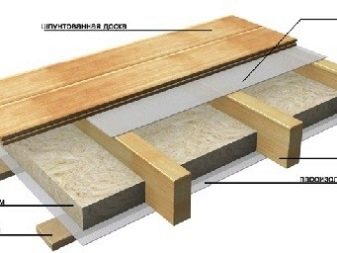

Wooden structures can not cope with heavy insulators, here you should give preference to mineral wool, which not only does not create additional load on the building supports, but also allows you to effectively produce condensate. Fiber insulation is mounted between existing beams, after which a vapor barrier is equipped,on the beams are mounted counterblocks, which will serve as the basic basis for the flooring of boards when equipping the floor in the attic or in the attic floor.

The technology of ceiling insulation from the attic is different for materials of different types.

When installing mineral (basalt or stone) wool or glass wool, in addition to the material itself, will require boards or metal profiles, tools for cutting insulation and fasteners.

- To begin with, a vapor barrier film is laid on the floor, and the work must be carried out in such a way that no gaps appear on the surface. The material fits overlap by 15-20 cm, and the seams are reinforced with special tape.

- A framework of bars or a metal profile is installed on the base prepared in this way, the distance between the elements of the sheathing should be 2-3 cm less than the width of the roll of fibrous insulation, the height should slightly exceed the thickness of the insulation. This is very important, because it helps to ensure free air circulation in the future.

- Then the mineral wool is unpacked and fixed in the space between the battens of the batten.

- If the insulation is made in several layers, then the material should be fixed so that each subsequent layer overlaps the seams of the previous one.

- Roofing material or another waterproofing coating is placed on top of the sheathing (do not forget that there should be free space between it and the mineral wool).

The technology works with the foam looks a little different. The foam is laid in two ways - on the glue or on the batten.

- Installation on the frame is a lot like work with mineral wool. The only difference is that the material is mounted on the side rails of the sheathing using liquid nails.

- But the description of the technology of working with glue corresponds to the following scheme. To begin with, the surface on which the solution will be applied is thoroughly cleaned from debris, dirt and grease. The coating is thoroughly cleaned, degreased, and then polished to smooth out any irregularities. If necessary, overlap ground. Then, the glue is diluted and applied to the sheets of foam, after a couple of minutes of waiting, the plate is pressed tightly against the floor surface and held to the required adhesion.Thus, the entire surface is processed, the joints of the material with the communications are processed with assembly foam or sealant.

Installation of insulation from Penoizol presents no difficulties. First you need to put a vapor barrier material, after which the space between the beams is filled with insulation so that the layer thickness is 20-30 cm. The roofing material is additionally placed on the surface of the coating and the plank floor is laid.

Work with ecowool is done in one of two main ways - dry and wet.

- The dry laying option suggests that the material should be put in pre-prepared cells of the ceiling. In this case, the insulating properties of the material are used only by 60-70% of the existing ones.

- The second method involves the use of professional equipment, which effectively moistens the material and then sprays it over the surface prepared in advance. The method is based on the features of ecowool becoming sticky when in contact with water, as a result of which the material fits tightly to the floor and adheres securely to its surface.Thermal insulation at the same time manifests itself more fully, but this method is impossible to implement on its own - the work requires the use of professional knowledge, skills and equipment.

The minimum ecowool layer required for effective warming is about 20-30 cm. However, the coating thickness may be higher if the work is carried out in a region with cold winters.

The most technologically simple variant of insulation is the use of expanded clay.which simply crumbles in the space between the beams on the previously laid layer of vapor barrier materials. Experts recommend the use of expanded clay of different factions. This provides less shrinkage and greater strength and efficiency of insulation. For regions of the average climatic zone, the material is applied in a layer of 20 cm, and for more severe conditions it can reach half a meter.

Sawdust is a cheap and affordable method of thermal insulation. To ensure greater efficiency of thermal insulation, this material is mixed with cement and lime at a ratio of 10x1x1. The components are thoroughly mixed to a dry mix.Then you need to take 5-10 parts of water, which is added a little copper sulfate (it serves as an antiseptic). After that, the mixture is again kneaded and applied over the surface.

You can be convinced of the readiness of the composition as follows: for this you need to squeeze a bit of the mixture in your fist. If the water does not drip from it, then the solution is ready for use.

Useful tips

The specified methods of insulation of the ceiling - this is the most popular methods of thermal insulation of the room, existing today. Whatever way and whatever materials you use, there are general requirements for this type of work that are subject to mandatory execution.

- Heat insulators that absorb water should be necessarily guarded on both sides by waterproofing materials. It is advisable to use them only in rooms with a normal level of humidity. The vapor barrier is placed on the side from which moisture and condensate are most likely to penetrate.

- The required thickness of insulation depends on the specific climatic belt and is calculated on the basis of the R-indicator of construction, which is 4.6-7.3 m2 / KW for residential buildings.

- There is no 100% moisture protection. Therefore, when insulating the ceiling, always use waterproofing materials.

- The materials used have their own advantages and disadvantages. From the point of view of price / quality ratio and ease of installation, mineral wool is considered to be the most optimal, it not only has a low cost and high quality, but it also contains a minimum amount of harmful substances.

- The most economical option would be sawdust or expanded clay. However, sawdust are short-lived, and not every building can withstand the weight of claydite. Polyfoam is relatively cheap and its thermal insulation properties are beyond praise, but this material emits harmful substances. True, in fairness, we note that their doses are minimal and harmless to health.

What material to choose and what method of installation to choose is a matter of taste. But in any case, high-quality insulation of the ceiling allows you to maintain a healthy microclimate in your home for many years and significantly save the cost of maintaining it.

In this video you will find a master class on weatherizing the attic floor with mineral wool.