Greenhouse "Droplet": features and specifications

Greenhouses "Droplet" - not a waste of money by modern gardeners and farmers. Many owners of personal plots have already managed to appreciate the advantages of this greenhouse. Summer residents interested in consistently high yields should definitely consider the features and characteristics of this structure.

Special features

Experienced gardeners know for sure that the choice of model and type of greenhouse should be approached with special care. Despite the fact that polycarbonate, for example, is considered to be a fairly durable material, the design features strongly influence many of the qualities of the finished structure. The building in the form of a drop deserves special attention of amateurs and professionals. The special properties of such a greenhouse are that it perfectly resists snow and winds.

The product is considered unique and is characterized by some features.

- Resistance contributes to the frame of steel. Reinforced arcs are fastened with special transverse parts.

- The main elements of fasteners are coated with anti-corrosion compounds. This is a guarantee against the occurrence of corrosion, which prolongs the operational life of the structure.

- Polycarbonate sheets, which are completed with the factory "droplet", are of high strength. The material does not chip, even with an exceeded strength index. It perfectly protects against the negative effects of UV radiation. Inside the structure accumulates the required amount of light rays.

- The frame of the greenhouse consists of profiled pipes of rectangular cross-section. The size of the parts used (20x20 or 20x40 mm) was not chosen by chance. Due to this design and withstands load power.

Advantages and disadvantages

Agronomists involved in the cultivation of vegetables in regions with difficult climatic conditions have long appreciated the best qualities of Kapelka greenhouses. Let's see more in the positive and negative features of this design.

Advantages:

- long service life;

- strength;

- optimal size range under the classic dimensions of the polycarbonate sheet;

- the possibility of changing the dimensions provided by the manufacturer;

- vents located at both ends of the structure make it easy to ventilate the interior space, this facilitates the care of plants;

- the structure can be easily adapted to any needs.

Disadvantages:

- the assembly of the classic greenhouse "Droplet" will take a lot of time and effort; the detailed description of the assembly steps, supplied with all the necessary details, makes it easier to task;

- the tightness of the “Droplet” ridge is unimportant, the construction loses in this respect to the arched or gable structures;

- for the “Droplet”, the presence of a skeleton is obligatory, whereas greenhouses of the arched type or greenhouses do not need a solid foundation.

Today, “Kapelka” is in demand in various Russian regions. It has positively proven itself in climatic zones with prevailing harsh conditions. Let us consider in more detail the characteristics of materials.

Manufacturing materials

The main element of any greenhouse - frame. Its strength characteristics largely determine the operating time of the construction.The frame of the greenhouse "Droplet" metal. Galvanized profile - the main material for the frame of the greenhouse. It is easier to work with the material, it also does not corrode. When using a galvanized profile is likely to damage the material of the shelter at the joints. Square galvanized pipe - 25x25 mm, 1.4 mm cross section.

Strength contributes to the frequent location of arcuate profiles. If the sheets will be supported by arcs that stand together, the distribution of snow load will be on the minimum area. Resistance will be the best.

Shelter material for the “Droplet” is cellular polycarbonate, it has conquered most of the market, albeit an expensive one. Greenhouse "droplet" comes complete with certified material shelter. Its advantages are in heat-insulating qualities, light transmission, resistance to mechanical damage, simple installation and low weight. The disadvantages of polycarbonate - in reducing the light transmission with time of use, in high cost.

For shelter of the greenhouse "Droplet" polycarbonate 4 mm thick is used. Important characteristics for the shelter material are UV protection and density.The main difficulty in using the material is the right choice of the coating side. You can find out which side is protected by several methods. The manufacturer usually marks the front side of the material with appropriate stickers or markers, it is enough to examine them carefully. If there are no labels or shipping packaging, the sun will help. On the protective side, violet highlights often play.

The density of polycarbonate can be determined by the weight of the sheets. In this case, the density of the sheets may be different, even if the thickness of the products is the same. Density values are easier to compare if you visually inspect sheets with a smaller and larger index. Internal stiffeners for sheets of 0.52 kg / m3 are less common than for sheets with a density of 0.72. Internal partitions of products with smaller indicators are thinner, and therefore the material has less stiffness. In thin sheets, the impact resistance is lost, the sheets break even under light weight.

Dimensions and assembly scheme

The dimensions of the greenhouse "droplet" are as follows:

- The height is presented in 2 versions - 1.7 or 2.4 m;

- width - 2.4 or 3 meters;

- product length varies from 4 to 12 meters.

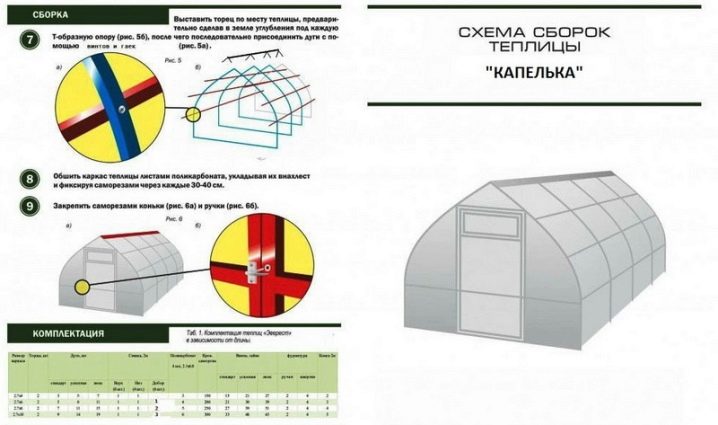

Consider a detailed scheme for assembling a greenhouse "droplet"

- It is more convenient to assemble elements, starting with doors and window leaves. Door pillars marked with numbers in the scheme must be fastened with crossbars. The total number of parts - 4 pieces. Inclined profiles reinforce the door frame. For their attachment it is convenient to use a universal connector.

- Take the vertical and horizontal fortochny profiles and fasten the details. Next, the window is installed in the upper part of the assembled door structure. You can begin assembling the gable part, which consists of arcuate profiles. One arc attached to the other, fastened with a special corner-tie, this should get a gable design. Screw the profile to the top with bolts horizontally. End rack elements and the bottom end face are mounted using similar connectors.

- Next, install the lower parts and grouser. Frontal sidewalls are fixed parallel to the ground. Identical actions going to another end, and then set the door. Lining the door, it is strengthened on the eyelets.

- The planes of the end part are mounted with universal connectors, of which there are only about 8 pieces. They are needed for the subsequent assembly of the body structure.Get ready to sheathe the end parts with polycarbonate sheets. To begin, make in the glasses the connection of the sheets with the skeleton of the hole into which the fasteners will then be inserted.

- The end pieces are aligned on the ground. Above you need to put a polycarbonate sheet with UV protection up. Fix the sheets with self-tapping bolts and cut with a cutter.

- We proceed to the stage of fastening the details of the structure itself. To do this, you need to lay the end parts on the surface and fix them with stringer profiles with the existing connectors in the end.

- Intermediate arcuate profiles are assembled, as is the gable part, which includes the same elements. We mount the lugs, X-shaped fasteners on the arc. Two parts of the X-type are interconnected by 4 bolts and cover the arcuate profile.

- The intermediate arc-shaped profiled pipe is installed from the end. It is necessary to ensure that the parts are equally located in relation to each other, as well as parallel to the ground.

- Next, you need to install a greenhouse. The selected area is freed from the ground, taking into account the required small holes for the lugs.The standard dimensions of the recesses are 0.2 m by 0.2 m.

- Assembled parts set in the grooves in the ground. The second row of stringer elements must be reinforced with X-joints. The remaining arcs are connected with stringer elements, and then mounted with the second end of the structure.

- The skeleton is leveled by level.

- Polycarbonate sheets for doors and vents easier to cut with a construction knife, taking into account the internal dimensions of the opening. The sheets need to prepare a place for the installation of loops. All fitting elements are mounted on the door and window. Cut polycarbonate sheets and proceed to their laying. Align the polycarbonate and fasten with bolts and washers.

- On the ridge of the construction we mount the corners. Details are connected with a special tape. We install the tie elements along the middle arcuate element on both sides of the structure, and then the long tie is pulled through all the elements and is connected to the short tie.

- Fasten polycarbonate sheets with screws in the holes of universal X-type parts. Self-tapping bolts are screwed into the first three rows of the profile, while the fourth row remains without fasteners.

- The pits under the building must be buried and the soil must be tamped down. Installation is complete.

Please note that after the correct assembly you should not have unnecessary elements. You can extend the life of polycarbonate, if after the end of the season to clean the sheets with a soft cloth soaked in soapy water. It is also worth making it a rule to regularly check fasteners and twist them if something is holding up badly.

Customer Reviews

Reviews about "droplet" mostly positive.

Buyers say:

- high quality;

- practicality;

- inexpensive cost.

Many come to the choice of this particular design after careful analysis of the offers on the market. Those who already use the design, note the earlier warming of the soil in comparison with the other options. Of the shortcomings, consumers have noticed a leak in the ridge, which is the most vulnerable spot of the structure. Constant ingestion of polycarbonate sediments reduces its light transmission ability. If improperly installed in a greenhouse, mist may form due to accumulated condensate, and this ruins the crop.

The durability and durability of the “Droplet” attracts the increasing attention of consumers.The manufacturer of these greenhouses has long been known in the market, as it has been supplying its products for more than 14 years. The design of the greenhouse is the best option for those who are looking for unusual solutions, but considering reinforced structures. Warranty load on the frame of the greenhouse up to 290 kg / square meter.

At high loads, the product may be deformed. To maintain the warranty quality for 10 years, you should consider the advice on operation and assembly. For example, as far as possible it is necessary to clear snow in the winter period. With the arrival of spring, it is worthwhile to carefully inspect the frame for possible damages and timely repair them.

For information on how to collect the droplet greenhouse, see the following video.