Greenhouse heating: options and features

The very word greenhouse hints directly and unequivocally: there must be warm. But the gloomy autumn or spring weather, short light day, rain and melting snow, penetrating the wind, wet and cold land - all this prevents it from justifying its name. That is why it is so important to take care of additional heat generation.

Special features

Heating a greenhouse is fundamentally different from generating heat for a private house, bath or garage. There are many more options, and therefore it is extremely important to understand all their features. Most systems for heating greenhouses in the winter can be done by hand. But it is important to remember that it’s impossible to control heating as carefully as at home — it’s impossible to “live” in a greenhouse.That is why it is so important to create not just a powerful system, but one that excludes temperature jerks.

When choosing the best option, pay attention to:

- energy efficiency;

- fire safety;

- the formation of an optimal microclimate for plants;

- ease of installation and operation;

- system reliability.

Pros and cons of ways

For heating greenhouses there are many options. Consider each of them in more detail.

Electric

Increasing the cost of all fuels is a trend that will continue for years and even decades to come. Therefore, among the electric methods of heating greenhouses, film variants have a clear priority. The thinnest (layer from 0.04 cm) film is a collection of current-passing strips, which are laid according to a special scheme.

Its advantages are:

- possibility of fixing on any solid basis;

- ease of connection to the mains;

- safety of use;

- excellent efficiency.

As for weaknesses, the minimum film thickness is the primary drawback. A small footprint results in a high risk of damage.Errors in the use of infrared coatings can lead to the need to call the Ministry of Emergency Situations.

More resistant mechanically option - heating cable. He is able to work from 20 years in a row, the system is included both on a large area and on separate sites.

Cable circuits in the "warm floor" format are the best choice compared to water systems. To switch the equipment from general warming up to local, you only need to perform 1 action with the simplest control device. Classic resistive cable is simple and cheap, the type of insulating sheath and external mechanical protection determines the period of operation.

Cable with a single residential will have to put so that both ends were near the power source. The only alternative is an additional cable for connecting the far end.

Resistive-type cables can adjust the amount of heat generated to warm the ground. But even in two adjacent beds, the actual temperature of the earth can vary quite a lot. Therefore, it is necessary either to customize everything “one size fits all”, or to create complex and expensive systems.Self-regulating cables are considered more modern, additionally saving current. Individual segments adapt the heat to a specific task; if a certain fragment is already heated, the cable will not work there.

However, there is another option - with the help of heating panels.

Panel heating method of greenhouses allows the installation of basic systems and near the ceiling and in the walls. The electrical version of the panels performs well if the area of the greenhouse is limited to 25 m2. In larger space, they are not economical enough. It will take a serious cable route and waste a lot of energy. In addition, in many country partnerships and country settlements the amount of consumed current per household is limited.

Speaking about heating with electricity, you can not ignore such an option as a carbon cord. Compared to other cables, it differs in thermal inertia (it is equal to 0), eliminates temperature jerks and helps to adjust the conditions to the arising needs smoothly. Carbon cable is combined with all known types of thermostats.Even when contour length adjustment is required, this is very easy and simple.

Its advantages and have a heat gun.

All electrical systems can do without such an element as a chimney, but the “gun” is simpler than the rest of the device. Completely eliminates the need for additional devices. The launch is made immediately after the acquisition

. It is recommended to mount the system on the ceiling to prevent damage to the landings. However, the power consumption is very high.

Sunny

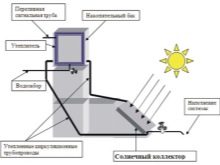

Heating due to the sun is considered the most natural solution, and modern methods allow it to be used both in the winter greenhouse and in the dark period of the day. Be sure to create a greenhouse made of polycarbonate or glass. But it is necessary to form the structure in the form of an arch and maintain orientation from east to west. To compensate for the short light day, the equipment of the greenhouse is made by a solar collector. It is formed in the form of insulated trenches, over which coarse sand is poured, an additional layer of soil is created.

If we compare such a scheme with air heating, it becomes clear that even the addition of improvised batteries does not increase efficiency sufficiently.The entry of heated air provides both stronger and faster heating. The only problem is that during the harsh winter a lot of fuel will be spent.

Biofuels

From ancient times, farmers use manure and a number of other organic substances to heat the land. The decomposition of organic matter releases a significant amount of heat. In many cases, preference is given to horse manure, which reaches 70 degrees in a week and keeps this figure for months in advance. If there is no such significant need, combine it with a straw. You can also mix manure with wood bark, sawdust and kitchen waste.

The disadvantages of biofuels are:

- subjective inconvenience;

- the risk of hygiene;

- unsuitability for warming up more than 4 months in a row.

Gas

In many suburban and country houses try to install gas stoves. And this suggests another way to correct the deficiencies of the greenhouse. The relative cost-effectiveness and simplicity of the system, the possibility of creating it from factory components are the main positive aspects.However, it is necessary, along with an exact calculation, to prepare drawings and a package of permits. Without the consent of the registering state bodies, it is impossible to implement the project, and each its alteration involves new expenses.

Natural gas is flammable, explosive and toxic. When using it, the greenhouse becomes an excessively wet place, and the concentration of carbon dioxide grows excessively. Additionally, air saturation with oxygen is reduced. Installation of ventilation complicates matters and requires additional calculations, and in the winter fresh air devalues the generated energy.

To reduce the cost of gas a little, the monorail type of water heating is practiced (with the connection of a coiled pipe to the pump).

The benefits of water

Heating a greenhouse with water heating is good because this option allows you to communicate heat to both the ground and the air.

Device

In contrast to the solar heat generation, it is possible to heat a large room on a year-round basis. What is important, completely eliminated the appearance of dry air.But the arrangement of ventilation is critical, since the immobility of air can lead to overheating of the plants.

If you use the classical air scheme, it is technically simpler, however, it consumes more energy and achieves an identical result at a significantly higher cost.

Boiler selection

It is necessary to pay attention to the correct choice of the boiler so that it satisfactorily performed the tasks. In the greenhouses, the installation of the same heating aids is practiced as in houses and in other buildings.

Greenhouse boilers can work on:

- waste of the wood processing industry;

- quality wood;

- black and brown coal;

- peat;

- domestic fuel litter;

- natural and liquefied gas;

- diesel fuel.

In many ways, the selection of a suitable system is determined by the personal taste and range of available energy sources. If the terrain has gas pipelines, it is best to connect to them. Even bureaucratic bastions do not detract from the economy of "blue fuel".

Electric or solid fuel boilers can also be used.It is necessary to carefully select the overall configuration power in order not to freeze the planting and pay only for the heat that is really needed.

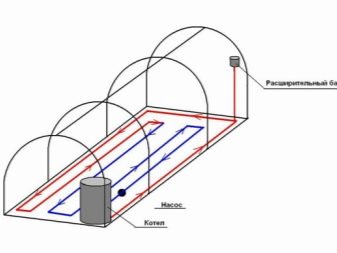

System installation

In addition to the boiler itself, it is necessary to install pipelines and associated radiators. The role of expanding tanks, chimneys and pumps that support circulation is great. Experts recommend forming a pair of heating circuits, rather than one. Under the ground settle one line, which is made of plastic pipes, which serve for the migration of water with a temperature of about +30 degrees. It is required to lay such pipes as close as possible to the roots.

The second tier is located under the dome and is made on the basis of radiators. Most often in the greenhouses use forced pumping circulation, much less frequently used gravitational course of water.

It is useful to supplement the heating circuit with thermal regulators that allow you to control the operation of the system in automatic mode. It will not be necessary to fear that in your long absence the greenhouse will overheat or overcool. Radiators in greenhouses are made of cast iron, aluminum or bimetallic.

For your information: there are systems in which there are no radiators at all. Then the space under the dome is heated with a round steel pipe of significant cross-section. Expansion tanks are made either open or closed, but without them, unlike radiators, systems cannot be mounted. Save is obtained in the case when the expanders do not buy, and brewed from metal sheets at home. As for the chimney, along with the traditional brickwork, the creation of asbestos-cement ducts and the use of steel pipes of round or square section are practiced.

If possible, it is recommended to take the pipes in a sandwich format. This is the most modern and practical solution. As for the circulating pumps, this is also not so simple, as most of the summer residents believe. In the greenhouses of the budget class, if the pressure drop is ensured, the gravitational mode of pumping can be used. Again, the choice of components is determined primarily by considerations of a material nature.

Furnaces or heating boilers are mainly placed in the vestibules of greenhouses, much less often they are given a place inside.The advantage of the external location is that the fuel stacked side by side does not interfere with the movement in the greenhouse and does not create problems during operation. But there is a plus in the internal location - it helps to obtain an additional amount of heat. We must weigh the pros and cons, evaluating the available space. Any boiler and any furnace necessarily deserve the installation of the foundation.

If the stove is laid out of brick, a concrete base is poured under it. But metal heat generators enough to put on a sheet of steel or asbestos cement. In any case, you should take care of the most reliable installation of the system.

When installing the chimney, attention is paid to ensure that any joint and rotation is thoroughly sealed. Even the best cement with a significant heat cracks, because instead it is necessary to use clay mortar.

Connection to the inlet and outlet nozzles of the boilers should be made using steel pipes that are identical in diameter. Only after 1-1.5 m they can be replaced with plastic elements. Expanding tanks put in the highest places of buildings near the stoves, boilers.They should be preceded by an automatic blocking valve in the hydraulic circuit, as well as a pressure gauge. When radiators are equipped with taps for cutting off, the inlet and outlet pipes must be separated by jumpers, then one stopped battery does not paralyze the entire system.

Heated soil is recommended to provide pipes on the basis of cross-linked polyethylene. It is very good when the circuit performing the similar task is complemented by the control automation. It should set the modes of operation, corresponding to the specifics of certain plants. The soil heating device in greenhouses itself is quite close to the well-known “warm floor”. Those who have already mounted such a floor are unlikely to face special difficulties.

An insulating layer of waterproof material helps to avoid heat loss in the ground, most often it is expanded polystyrene. Strengthen the waterproofing properties helps plastic film. The pipes are laid out on a sand cushion, which have been pre-washed and compacted after backfilling. The thickness of the cushion should be 100-150 mm, this will ensure even heating and zero risk of overdrying of the ground; 300-350 mm of fertile soil must be put above the heating layer.

Oven

One of the most popular solutions for summer cottages is stove heating of greenhouses, but also having its own advantages and disadvantages.

Advantages and disadvantages

Suppliers of all boilers and other heating elements for greenhouses focus on high efficiency. But modern stoves demonstrate an equally impressive efficiency. Therefore, it is naive to regard them as frivolous rivals of boiler equipment.

The main advantages can be considered:

- low cost of heating on solid fuel, wood or waste oil;

- the simplicity of the system itself (ease of installation and maintenance);

- wide availability of the required fuel.

Most often in the greenhouses put iron stoves, which quickly warm up, but quickly and lose their heat. The disadvantage of such devices can be considered and their "tendency" to the desiccation of air. Even for plants that are accustomed to the dry and hot atmosphere, this is unlikely to benefit.

The use of water circuits performed in the form of radiators or registers helps to reduce the sharpness of temperature jerks.

Selection and installation of the furnace

Classical solid fuel stove is demanded mainly in greenhouses,used in spring and summer.

Such structures are much more mobile brick and remove the obligation to form the foundation. Another important circumstance is the minimum absorption of useful space. It is necessary to take into account such advantages of metal furnaces as cheapness, the ability to install with your own hands without mastering the art of laying bricks. As for weaknesses, it is necessary to mention the unsuitability of such stoves for automation. Chimneys removed from metal furnaces should be set at an angle of at least 15 degrees to increase heating.

The metal pipe itself must be devoid of any insulation. But at the intersections with the apex or wall, it is required to mount the box impermeable to heat. Any steel furnace should be installed in such a way that its fall is completely excluded. Many times such events have caused fires and loss of property.

In regions with harsh weather conditions, coal-fired furnaces can be used, which emit more heat and retain it longer.

But the problem is the increased amount of waste and the increased toxicity of combustion products when usingcoal fuel. Some of its types can light up on their own and deserve specific conditions for accumulation. In recent years, the popularity of stoves on sawdust or fuel briquettes, which are made standard in performance and emit a minimum amount of smoke, has grown.

But diesel furnaces are not suitable at all. They emit poisonous smoke, besides the slightest misstep can cause an emergency.

What is guided when choosing?

Speaking about the best projects for heating the greenhouse, it is worth noting that they do not include the use of convectors. By themselves, they only heat the air, and the soil layer stays cold, just as before the system was turned on. Therefore, we have to take care of biological heating, which is extremely important for frosts in early spring. But there is a better strategy - the use of a heater system in the form of mats or cable layouts (heating tapes). For winter, this solution is just perfect, especially because it allows you to warm only those places that are really needed.

The risk is that the slightest mistake in calculating the required temperature can burn the roots of plants. Geothermal heating of greenhouses in a small private sector is completely unprofitable, since it requires very large investments in equipment and begins to give returns too late. The use of solar batteries or heating lamps is auxiliary. The former deal mainly with the effects of a cold summer, while others are needed to create optimal conditions for seedlings. Therefore, a serious choice arises only between electric heating (including infrared) and boilers (stoves) on various types of fuel.

Popular species

If it is necessary to heat the greenhouse economically and simply without electricity and without gas, the choice naturally leans in favor of the biological method. Gardeners who are accustomed to working in the ground and in contact with dirty substances, such heating will not cause any special mental torment. In addition, it is completely environmentally safe and allows you to warm up the beds. In northern latitudes and in places with an unstable, unstable climate regime, heating of the greenhouse space can be done cheaply only relatively, because one or another fuel will still have to be spent.If the plot is gasified and the area of the greenhouse is small, you can power the burners or heaters from the cylinders.

If the heated beds are very large, it is impossible to consider such a method economical. We'll have to connect to a centralized system of heating the site or look for other ways. The high cost of electric current, as already mentioned, has a somewhat lower effect on the costs of gardeners when choosing a rail circuit. Instead of infrared film or "warm floor", you can still use water pipes connected to an electric boiler. But here the system becomes more complicated, and it is rarely possible to mount it without the help of professionals.

About water heating in the greenhouse with their own hands, see the following video.