What to do if the faucet in the bathroom drips?

Even the most expensive and reliable faucets sooner or later begin to pass water. Few people can safely endure the sound of a dripping faucet, not to mention the fact that this significantly increases water consumption and creates the threat of flooding.

If such a problem arises, you should get rid of it: You can call the plumber, and you can try to adjust the problem yourself.

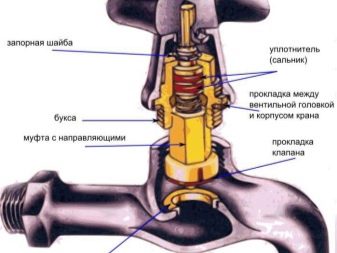

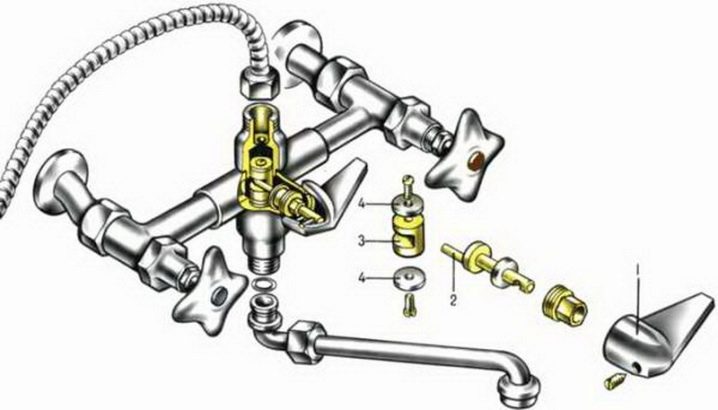

Features of the device

First, let's look at the question theory a bit. In each shower room and kitchen there are taps and mixers. The former are responsible for the flow of water, and the latter make it possible to regulate the required temperature by mixing hot and cold streams.

Valves are divided into single and double valves.

The mechanism of operation of a single-valve mechanism is simple, since it is used for the inflow of only one type of water, either hot or cold.It is equipped with metal or ceramic boxes, consisting of two firmly pressed between the plates. When you turn the lever of the crane, these bushings change their location and then the water begins to flow to the user. It should be noted that the use of such a crane will become significantly longer if you replace the cartridges and plates. Optimally, the spout of the product is made of materials resistant to corrosion, such as brass or, for example, copper, because even alloyed steels begin to become covered with corrosion scabs over time, which often serves as the main reason that the crane runs.

The two-valve mechanism is considered to be an analogue of a mixing device, the flow of water is also controlled using special cranes-boxes, which are most often performed in the form of balls or plates.

Water can flow from various places of the device:

- From under the valve - a similar violation usually indicates that the rubber liners are worn out.

- If a leak is observed from the outflow, it means that the crane-box has worn out and its edges have stopped blocking the flow of water.In this situation, you should simply replace the new part of the crane that failed.

- If a leakage arose between the spout and the mixer, it makes sense to replace the liners or check whether the valve was installed correctly - usually a problem arises when it is too tight.

- If water seeps between the faucet and the sink, you just need to turn the faucet on. Most likely, he loosened over the years of operation.

But if problems are associated with damage to the mixer, then there is no point in carrying out repair work - it is much easier to purchase a new one and install it in accordance with all the rules.

It is obvious that in most cases it is quite simple to fix the dripping valve, you just need to know the exact cause of the leak.

Possible reasons

The problem of the flow of a crane occurs quite often, while the reasons that cause it, not so much.

Like any other item, the crane has its own technical parameters, and each manufacturer gives a guarantee on their products only if they are properly used. If the user makes more efforts than the features of the device require, for example,presses the handle too hard when turning, presses under the wrong angle or presses the crane elements during installation, then the breakdowns will not take long to wait.

Often, when buying plumbing, we try to save money by choosing products whose prices are much lower than the market average, but the products visually do not have any differences from the more expensive models.

As they say, the miser pays more, and this dubious economy often leads to leakage. - and this is at best, and at worst it can trigger a local accident. The reason for this is the low quality of internal materials that very quickly deteriorate and wear out, rust or break. When buying a faucet or mixer, it is better to choose products from proven manufacturers, regardless of their cost. Just imagine what can happen if an unexpected crane breaks down while there is no one at home who could cut off the water supply - it is possible that repairs will be needed, not only in your house, but also in your neighbors.

Wear

Nothing lasts forever, and faucets with mixers too. Water turns on and off dozens or even hundreds of times throughout the day, so sooner or later the moving parts start to wear out and cause the entire mechanism to break.Most often, problems are solved by simply replacing parts that have become unusable. However, experts recommend updating the mechanism in advance, without waiting for a leak, for example, the same gasket can be changed every 1-2 years - this will prevent many unpleasant defects of the crane operation.

Sometimes a breakdown causes a factory defect. Since the cranes themselves are sold at points of sale already assembled, the only place where you can make a mistake when carrying out installation work is the place of junction with the pipeline, therefore, the main cause of leakage should be sought precisely in this area. If the faucet directly drips, then in most cases you are dealing in a defective product. Then there is only one way out - to return low-quality products to the store.

But for the most part, problems appear because of mistakes made during the installation of the system. If the parts were assembled in the wrong sequence, too tightly or, conversely, loosely tightened, then this will inevitably cause a leakage, and in the short term. Therefore, if you do not have the skills of relevant work,it is better to entrust the installation of the device to professionals - in the end, you install the tap once for many years, and the cost of such services is quite small.

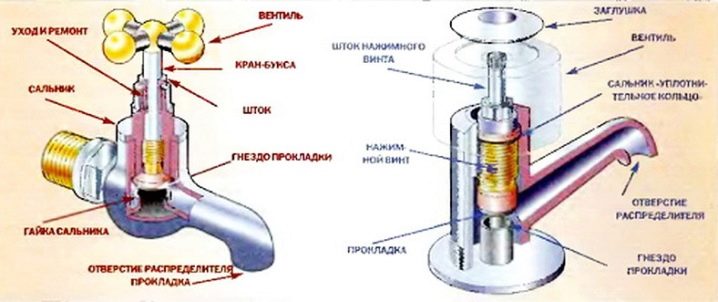

If we talk about the breakdown of specific parts of the crane, then most often problems arise:

- With gasket. This is a natural process - as the crane is used, the material of the liners loses its shape, cracks and changes in its dimensions. If the tap drips even in the off position, then most often the problem lies in the rubber liner. Repair in this case comes down to removing the old element and installing the new one.

- With the gland. In general, the stuffing box cuff, regardless of the manufacturer of the crane, wears out pretty quickly, this is its extremely unpleasant feature. It is very easy to diagnose such a problem - if the faucet does not have any external signs of damage, but when the fluid is turned on, water begins to flow out from under the valves - this means that the worn oil seal is to blame, it should be replaced with a better new one.

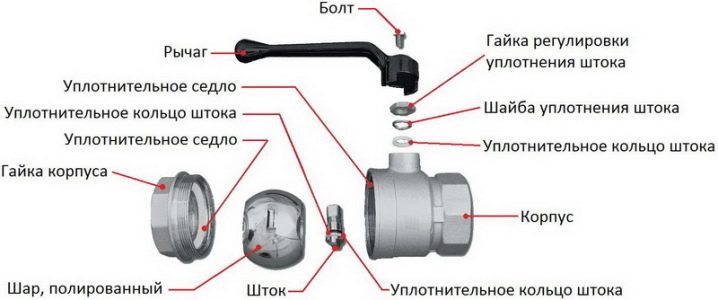

- With ball cartridge. Ball valve can not be called a perfect design, inside it there are many elements that are tightly attached to each other.Such elements are very negatively perceived by any mechanical inclusions and impurities in the fluid flowing through the valve. To adjust this problem, the faucet needs to be completely disassembled and cleaned.

Sometimes there are several breakdowns at the same time - in this situation it is better to install a new crane.

Repairs

Single lever

Single lever mechanisms can often be repaired on their own without recourse to the services of specialists. The procedure for this depends largely on the features of the device.

To carry out repairs on the crane you need to prepare the inventory:

- new cranes;

- a set of various keys;

- several types of screwdrivers;

- gasket parts of different sizes;

- tape for sealing parts of a threaded structure;

- electric drill;

- silicone seals.

If the cause of the breakdown is in complete wear of the rubber gasket, then it is necessary to put things in order as soon as possible, otherwise the internal parts of the body will begin to leak, and scum may appear on the basic components. In this situation, replacing the gaskets is not enough, you have to purchase and install a new mixer. Change this gasket is not difficult.

For this:

- the flywheel is removed from the spindle, and then the core is carefully unscrewed with a prepared open-end wrench;

- old gasket is removed - as a rule, it is located on the back of the core;

- from a strong piece of rubber make a new seal, which by its shape should correspond to the size of the old part;

- the cut element is fixed in place of the former;

- the entire crane mechanism is assembled in reverse order.

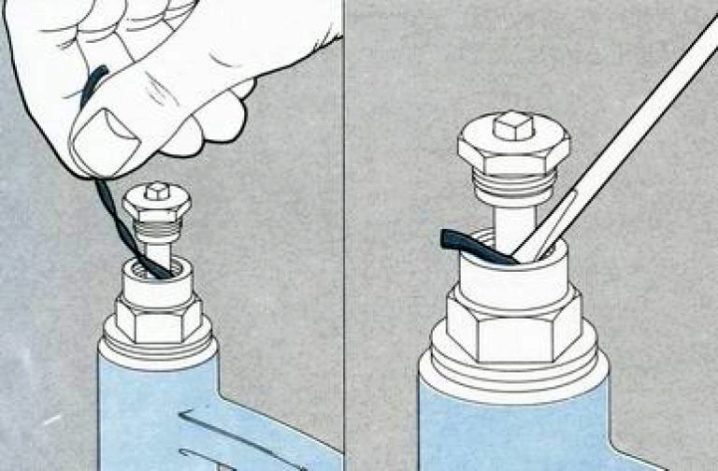

Another common cause of a kitchen tap leaking is the deformation of the gland. In this situation, a leak occurs at the time of opening the tap.

Repair in this case is made according to the scheme:

- using a thin screwdriver gland nut is reversed;

- A new oil seal is cut out of the fum tape and wound on the old valve:

- the crane is assembled and the nut is tightly twisted.

If all the manipulations were done correctly, then after turning on the water re-leakage will not occur.

Another common cause of estrus of a single-lever mechanism is associated with wear of the gander, more precisely, of the part that is installed on it. With such a problem, the tap dripping occurs continuously, and quite abundantly.

In order to change the liner on the gander, it is necessary to unscrew the fastening nut, for which purpose an adjustable wrench is used. Then the procedure is standard - the damaged liner is removed and a new one is attached in its place.

Separately, we should talk about the repair of popular ball valves. The most common cause of damage in them is garbage accumulated inside the case itself.

In this case, the repair work on the device is performed in the following sequence:

- gently unscrew the screw holding the handle;

- the handle is carefully removed from its base;

- unscrew the screw with a screwdriver;

- further it is necessary to remove the cover, as well as the plastic seal;

- then you should inspect the entire gasket and remove all the dirt that has accumulated inside;

- if the item is outdated, you should buy a new one and fix it instead of the unusable one;

- then the ball is taken out; if it has deteriorated, it should also be replaced;

- remove the ball seals with a very thin screwdriver, which must also be replaced with new ones;

- after replacing the elements, they should be lubricated with a special compound;

- all manipulations are performed in the reverse order to assemble the crane.

Work should be done with great care, since the ball valve is quite easy to damage.

Two-valve

Two-valve design involves the supply of hot and cold water using two different valves. The most unprotected element here is considered a rubber gasket, which must be replaced with a new one.

The sequence of actions is standard: First, turn off the water tap and drain the remaining liquid from the mixer. Then gently pry the artificial cover, which is located under the screw of the flywheel. To do this, you need to use a very thin screwdriver, and then directly unscrew the screw and remove the flywheel. This must be done very carefully, so as not to damage the surface of the crane.

Then unscrew the stem with a rubber liner and inspect the valve near the base of the mixer. If scale or other defects are found in it, they should be cleaned, then you can replace the gasket with a new one and install the valve back.

After the work done, you need to turn on the tap and make sure that the problem is fixed. If the valve continues to leak, it makes sense to tighten the gland seals.

If the valve has dripped even when turned off or while rotating with the lever, you hear an unpleasant crackle, this may indicate wear on the sealing gum. The problem is solved quite simply: the valve must be removed, the bush removed and the gasket replaced, after which the thread should be sealed with a special tape and the valve returned to its place.

Sometimes the problem is due to the fact that the axle box is not tight enough to the mixer. Then there is also often a leak. In order to remedy the situation, it is necessary to tighten the existing threads and firmly tighten the nut.

If this did not have the expected effect, then most likely it is necessary to replace the bush.

Replacement works are performed in the following order:

- the cap is removed from the flywheel, after which the valve is removed;

- the thread and the flywheel are cleaned from inside of debris, rust scabs and other defects;

- elements of the dripping tap are unscrewed; for this purpose, various types of mites will be useful;

- then the bush is removed directly and now the mixer thread is cleared of impurities;

- in place of the old axle box a new one is screwed in; but note that if you didn’t thoroughly clean the threads,then the bush will not fit snugly enough;

- assemble the crane back.

How to repair the switch to the shower?

To understand that the shower switch requires repair is very easy - usually in case of failure, it immediately begins to drip and leak.

As practice shows, the most common cause of leakage is the wear of the old rubber ring, which is located between the switch knob and the main body.

To eliminate the damage, it is necessary to block the flow of water, after which the handle is disconnected from the tap. Further, the screw is carefully unscrewed from the switch and removed. After these manipulations are carried out, the old ring should be removed and a new one should be fixed in its place, and where the lever is fixed, a special tape of 3-4 layers is applied to the thread. Then the lever returns to its original place and is fastened with a screw.

If the switch is spool, quite often the nut that holds it breaks. This problem can also be resolved on its own. To do this, it is necessary to remove and completely disassemble the mixer, but it is very important that all its elements are disconnected.If a surface inspection reveals that the nut threads are fully or partially worn, then it should be replaced with a new one. Optimally, if you make it bronze - this material is more resistant to moisture and durable. If there is no need to replace the nut, then you need to clean it with sandpaper, lubricate all the elements of the mechanism with grease and reassemble the mixer.

When working on repairing a crane, it is very important to shut off the water. Otherwise, if something goes wrong, you will not avoid a large influx of water.

Tips

Despite the fact that even a person without experience in plumbing can easily cope with the repair of a dripping faucet, it is better to prevent these unpleasant situations from occurring than to waste time, effort and money on eliminating their consequences.

The main enemy of plumbing of any type is low-quality water. It is tough, it contains various salts and mechanical impurities, which can quickly disable even a very expensive and reliable mixer or faucet. It is very important to prevent solid particles from getting into the parts of the mechanism. Keep in mind that traditional rubber liners, which are mounted in the most simple taps, are much more resistant to wear than those parts, the base of which is ceramics.The latter almost immediately become scratched and begin to crumble, passing water. To prevent the occurrence of such problems is extremely simple - for this it is only necessary to use a mechanical cleaning filter built into the water supply system.

Pay special attention to water hardness. Try to reduce its level as much as possible, since an excess of carbonates forms scum, which destroys taps, as well as kettles, coffee makers, dishwashers and other appliances. To neutralize their adverse effects, it makes sense to install a filter with water softener functions.

You can forget about the problems with a crane for a long time if you give preference to products made of durable materials. Parts of brass and other heavy metals and alloys are characterized by the longest period of use, but products made by silumin from Chinese and Turkish manufacturers will not last long - it is very fragile and becomes unusable very quickly.

Some manufacturers offer a faucet, a cartridge in which is glass, but it is better to entrust its repair to professionals, since working with glass requires experience and utmost care.

Pay attention also to the fact that any rubber ring can be easily made by ourselves, but, nevertheless, such a part has a rather short period of use, therefore it can only be considered as an emergency measure. Such rings should be replaced by permanent at the earliest opportunity.

Well and in conclusion we will give a small overview of the manufacturers of faucets and mixers, whose products have enjoyed an impeccable reputation in the market for several decades.

The palm is undoubtedly given to German manufacturers, such as Hansa, as well as Grohe and Hansgrohe. These companies successfully sell their products over the course of a century and are durable and reliable products made of brass with a warranty period of 10 years.

Italian brands are very popular. Among the most sought after are Gessi, and Visentin, as well as the French Delafon. The choice of these brands means the ideal ratio of truly European quality and optimal price.

Finishing top five finnish taps for the bathroom and options for the kitchen from the company Oras and products of the Spanish concern Teka.

How to fix the faucet in the bathroom, see the following video.